Drilling Machine: What You Need to Know in 2025

Introduction

Whether you’re anchoring a frame to concrete, boring holes through steel, or installing kitchen cabinets, one tool is nearly always involved, the drilling machine. In 2025, this essential tool has evolved beyond the simple handheld drill, offering a variety of specialized functions for different industries and materials.

From home repairs to industrial construction, drilling machines continue to power efficiency, speed, and accuracy. As Nigeria’s demand for quality tools rises across sectors like construction, metal fabrication, carpentry, and electrical installations, understanding the right drilling machine to use has become just as important as knowing how to use it.

Read more...What is a Drilling Machine? Everything You Need to Know

In this article, we’ll walk you through:

- What a drilling machine does

- Key components

- The latest types and technologies in 2025

- How to choose the best one for your specific job

Key Takeaway

- Smart Features Are Leading the Way: Drilling machines in 2025 come equipped with digital interfaces, speed controls, and safety sensors, improving precision and reducing user fatigue.

- Cordless and Brushless Tech Dominate: Battery-powered and brushless motor drilling machines are now preferred for their efficiency, longer lifespan, and maintenance-free operation.

- Multi-Purpose Drills Offer More Value: Modern drilling machines are increasingly multi-functional—capable of drilling, screwing, and even chiseling—making them ideal for both professionals and DIYers.

What Is a Drilling Machine?

A drilling machine is a power tool or machine used to create round holes in solid materials like wood, metal, concrete, or plastic by rotating a drill bit into the surface. But in reality, it does more than just "drill" — many modern machines can also tap, countersink, bore, and ream depending on the bit and functionality.

Drilling machines are used in both light-duty tasks like hanging picture frames or assembling furniture and heavy-duty industrial jobs like steel fabrication, bridge installation, and factory maintenance.

Main Parts of a Drilling Machine

While models vary, most drilling machines include the following key components:

- Motor: The powerhouse that rotates the drill bit.

- Chuck: Holds the drill bit in place and tightens around the shank.

- Spindle: Transfers rotational motion from the motor to the chuck.

- Drill Bit: The cutting tool that bores into the material.

- Trigger or Switch: Controls operation and speed.

- Base or Handle: Offers grip, stability, and/or mounting surface.

- Gear System (in heavy-duty models): Allows speed adjustment and torque control.

Understanding these components is key to selecting the right drill based on the material, depth, and hole size required.

Types of Drilling Machines in 2025

Different tasks require different types of drills — and in 2025, the range is more versatile than ever. Here are the most common types used in Nigeria:

Portable Electric Drill

Also known as a handheld drill, this is the most common tool for general use at home or in small workshops. It’s lightweight, easy to operate, and perfect for:

- Installing wall anchors

- Assembling furniture

- Light wood or metal work

Available in corded (requires plug) and cordless (battery-powered) models.

Popular Brands Available:

Dongcheng, Ingco, Maxmech

Bench Drilling Machine

Bench drills are mounted on a workbench or table and are typically used in carpentry shops, mechanical workshops, or school labs. These offer more precision than handheld drills and are ideal for repetitive tasks like:

- Drilling precise holes in wood or plastic

- Light metal boring

- Drilling at fixed angles

Recommended Brands:

Bosch, Dongcheng

Pillar/Column Drilling Machine

This heavy-duty drill is fixed to the ground and can handle more substantial materials. Great for:

- Steel and aluminum fabrication

- Mechanical parts assembly

- Workshop production lines

Best For: Workshops, light industrial setups

Available Brands: Maxmech, Dongcheng

Radial Drilling Machine

The radial drill features a movable arm that allows the drill head to travel along a horizontal axis. This gives it excellent flexibility, making it ideal for drilling large or heavy workpieces that cannot be easily moved. It is commonly used in:

- Metalworking shops

- Heavy machinery assembly

- Structural steel fabrication

Because the workpiece can stay stationary, operators enjoy improved accuracy and safety when handling bulky components.

Best For: Factories, fabrication plants

Available Brands in Nigeria: Typically imported — GZ Supplies can help source via request

Magnetic Drilling Machine

Also known as a mag drill, this machine uses a powerful magnet to cling to a steel surface, allowing for vertical, overhead, and horizontal drilling operations. Common on construction sites and shipyards, it's ideal for:

- I-beams and steel frames

- Bridge and building fabrication

- Mobile installation crews

Some 2025 models come battery-powered, offering portability and power in a compact design.

Popular Brands: Dongcheng (corded options), Bosch (high-end magnetic models)

CNC Drilling Machines

CNC (Computer Numerical Control) drills are automated and used in advanced manufacturing facilities where high-volume, high-precision holes are required. Controlled by software, CNC drills:

- Minimize human error

- Allow repeatable, complex drilling operations

- Are integrated into wider CNC milling and fabrication lines

Best For: Automotive, aerospace, electronics, high-end metal fabrication

Note: Not yet common in general workshops due to high cost.

What’s New in Drilling Machines (2025)?

Technology in drilling tools continues to evolve, making them smarter, safer, and more efficient. Here are some 2025 innovations now seen in Nigeria’s market:

Brushless Motors

- Found in newer cordless drills

- Offer more torque with less heat and longer motor life

- Lower maintenance and quieter operation

Dual-Speed and Torque Control

- Enables better control for drilling into different materials

- Automatically adjusts power to protect drill bits and material surface

Digital Displays & Laser Guides

- Display drilling depth, battery status, and overheating warnings

- Laser pointers assist with alignment for precision drilling

Anti-Vibration + Ergonomic Handles

- Reduces user fatigue and improves grip

- Helps contractors work longer with greater comfort

Smart Battery Systems

- Fast-charging lithium-ion with up to 4X runtime

- USB-C charging ports on drill bodies for mobile integration

Applications of Drilling Machines in Nigeria

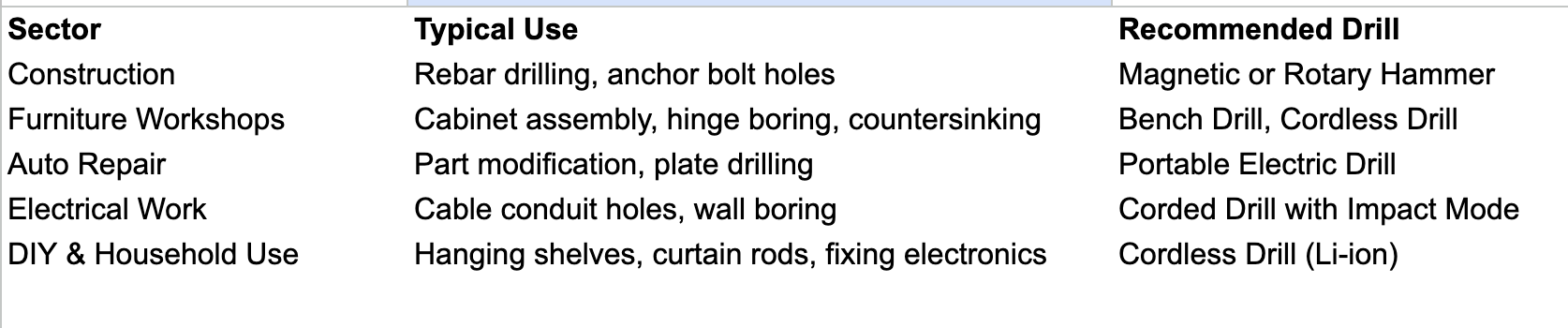

Drills are everywhere—from the construction of Lagos skyscrapers to local furniture shops in Aba. Here’s how they are being applied across sectors:

Maintenance Tips for Drilling Machines

To extend the life of your drilling equipment and maintain safety and performance, follow these best practices:

Lubricate Moving Parts

- Apply machine oil to spindles, chucks, and moving joints to prevent friction and wear.

- Especially important for bench, pillar, and radial drills.

Clean After Use

- Remove dust, chips, and residue from the chuck, bit, and body after every use.

- Use a dry brush or compressed air.

Check Battery Health (Cordless Models)

- Charge only with recommended chargers.

- Store lithium-ion batteries in a cool, dry place.

Inspect Power Cables & Plugs

- Look for exposed wires or frayed cords.

- Replace damaged cords immediately to avoid shocks or fire.

Sharpen or Replace Drill Bits Regularly

- A blunt bit causes more strain on the motor and leads to poor drilling accuracy.

- Use the correct bit for wood, metal, or concrete.

Top Drilling Machine Brands Available at GZ Supplies

Dongcheng

- Rugged, affordable, and great for both beginners and professionals.

- Available in corded, cordless, and rotary models.

Bosch

- High-end precision tools with innovative features like anti-vibration and smart depth control.

- Great for industrial and high-performance tasks.

Ingco

- Budget-friendly with surprising power.

- Ideal for SMEs and semi-professionals needing performance at a low cost.

Maxmech

- Known for robust builds.

- Excellent for rough job sites, masonry, and concrete drilling.

Frequently Asked Questions

1. What’s the best drilling machine for home use?

A cordless electric drill (12V or 18V Li-ion) is best for most household DIY tasks.

2. Can I use the same drill for concrete and metal?

Not ideally. Use a rotary hammer for concrete and a standard drill with metal bits for steel or aluminum.

3. What safety gear should I use?

Always wear safety goggles, gloves, and ear protection during extended use.

4. How do I know which drill bit to use?

- HSS (High-Speed Steel): for metal

- Carbide-tipped: for concrete

- Brad point bits: for wood

5. What’s the difference between a drill and an impact drill?

An impact drill delivers rotational force + concussive hits, making it ideal for tough surfaces like brick or concrete.

Related Article

How to Choose the Right Drilling Machine for Your Project

Choosing the Best Drilling Machine for Your Workshop in Nigeria

Best Drilling Machine for Home Use

Conclusion

Drilling machines remain one of the most indispensable power tools in every professional’s toolbox. In 2025, with brands offering smart features, longer runtimes, and ergonomic builds, choosing the right drill means faster work, better results, and fewer repairs.

Whether you're a furniture maker, technician, builder, or DIY enthusiast, GZ Supplies offers the right drill for your job at the right price.