Welding electrodes for Nigeria

We sell Welding electrodes for Nigeria workshops available online from GZ industrial supplies.

GZ Industrial Supplies Nigeria is a significant supplier of welding supplies Nigeria. We are also a stockist of welding electrodes mild steel, low hydrogen, stainless, hard facing, and M & R sell mild steel, low hydrogen, stainless, hard facing, and M & R electrodes. The complete product line offers reliability and performance in all welding applications. Our operating procedure is focused to help the customer get the best welding materials their, iron welding or any metal.

About electrodes

The MIG welding rod is a continuously fed wire referred to as wire. An electrode is a metal wire that is coated. It is made out of materials with a similar composition to the metal welded. There are a variety of factors that go into choosing the right electrode for each project. SMAW or stick electrodes are consumable, meaning they become part of the weld, while TIG wires are non-consumable as they do not melt and become part of the weld, requiring the use of a welding rod.

Welding wire selection is critical to ease cleanup, weld strength, bead quality, and minimizing any spatter. Electrodes must be stored in a moisture-free environment and carefully removed from any package (follow the directions to avoid damage).

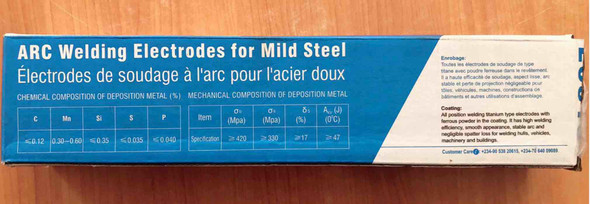

When molten metal is exposed to air, it absorbs oxygen and nitrogen and becomes brittle or is otherwise adversely affected. A slag cover is needed to protect molten or to solidify weld metal from the atmosphere. We can obtain this cover from the electrode coating. The composition of the welding electrode coating determines its usability and the composition of the deposited weld metal, and the electrode specification.

The formulation of this product.

The formulation of Welding rods is based on well-established principles of metallurgy, chemistry, and physics. The coating protects the metal from damage, stabilizes the arc, and improves the weld in other ways, which include:

- Smooth weld metal surface with even edges.

- Minimum spatter adjacent to the weld.

- A stable welding arc.

- Penetration control.

- A robust and tough coating.

- Easier slag removal.

- Improved deposition rate.

The metal-arc electrodes may be grouped and classified as bare or thinly coated electrodes and shielded arc or heavy coated. The covered electrode is the most popular type of filler metal used in arc welding. The composition determines the usability its use, deposited weld metal, and the specification of the electrode. The type of electrode used depends on the specific properties required in the weld deposited. These include corrosion resistance, ductility, high tensile strength, the type of base metal to be welded, the position of the weld (flat, horizontal, vertical, or overhead), and the kind of current and polarity required.

How to choose welding electrodes?

Choosing an electrode is determined by the requirements of the welding job. but take note of this option:

- Tensile strength

- Ductility

- Corrosion resistance

- Base metal

- Weld position

- Polarity

- Current

There are light and heavy coated electrodes. Light coated electrodes have a light coating that is applied through brushing, spraying, dipping, washing, wiping, or tumbling. Heavy coated electrodes are coated by extrusion or dripping. There are three main kinds of heavy coatings: mineral, cellulose, or a combination of the two. Heavy coatings are used for welding cast iron, steels, and hard surfaces.

GZ industrial supplies know the proper application and use of electrodes call on our experts at all times, we supply various brands of electrodes like Lincoln, Ador, Hyundai, Powerflex, including Nigeria brands like Samurai.

call +234 8181069339 or contact us for a quick cost-free quote

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Esab Stick Welding Electrode 3/32 x 14in 5kg E6013 Sureweld series

Esab

Esab Stick Welding Electrode 3/32 x 14in 5kg E6013 Sureweld series GZ Industrial Supplies Nigeria is the distributor of Esab welding products in Nigeria. Our Esab Stick Welding Electrode 3/32 x 14in 5kg E6013 Sureweld series, is the perfect...Qty in Cart: 0Quantity:Price:Subtotal: -

Gun Welding Machine 250A ExpressWeld

ExpressWeld Welding Equipments

₦98,900.00Gun Welding Machine 250A ExpressWeld (ExpressWeld250A) GZ Industrial Supplies is the distributor of ExpressWeld Welding Equipment in Nigeria. This Gun Welding Machine 250A ExpressWeld is a great choice for light and compact machine that...₦98,900.00 -

Mild Steel Welding Electrode 4mm Oerlikon PRIMAFIXIE

Oerlikon Welding Electrode

₦0.00Mild Steel Welding Electrode 4mm Oerlikon PRIMAFIXIE GZ Industrial Supplies is the distributor and supplier of Oerlikon Welding Electrodes in Nigeria. This Mild Steel Welding Electrode 4mm Oerlikon PRIMAFIXIE is a metal...₦0.00 -

Mild Steel Welding Electrode 2.5mm Oerlikon PRIMAFIXIE

Oerlikon Welding Electrode

₦0.00Mild Steel Welding Electrode 2.5mm Oerlikon PRIMAFIXIE GZ Industrial Supplies is the distributor and supplier of Oerlikon Welding Electrodes in Nigeria. This Mild Steel Welding Electrode 2.5mm Oerlikon PRIMAFIXIE is a...₦0.00 -

Stainless Steel electrode ASKAYNAK-AS-P309L-17 5kg pack

Askaynak

Stainless Steel electrode ASKAYNAK-AS-P309L-17 5kg pack GZ Industrial Supplies is the major distributor of Welding electrode in Nigeria and the supplier of Askaynak electrodes in Nigeria, Our Askaynack stainless electrode (AS P-309L -17 )is a...Qty in Cart: 0Quantity:Price:Subtotal: -

Askaynak Electrode E7018 (Low Hydrogen) 2.50 X 350 mm -1 Pack 4kg

Askaynak

Askaynak Electrode E7018 (Low Hydrogen) 2.50 X 350 mm -1 Pack 5kg GZ Industrial supplies have large stock of ASkayNak Welding consumables, Our Askaynak Electrode E7018 (Low Hydrogen) 2.50 X 350 mm -1 Pack 5kg is a basic coated...Qty in Cart: 0Quantity:Price:Subtotal: -

Samurai Welding Electrode Mild steel E6013 2.5mm 350mm

Samurai Welding electrodes

₦0.00Samurai Welding Electrode Mild steel E6013 2.5mm 350mm GZ Industrial Supplies Nigeria is the distributor and supplier of Samurai Welding electrodes in NIgeria, Our Samurai Welding Electrode Mild steel E6013 2.5mm 350mm₦0.00 -

Hyundai Welding electrode low hydrogen E 7018 4.0mm for stick Welding

Hyundai

₦5,213.75Hyundai Welding electrode low hydrogen E 7018 4.0mm for stick Welding GZ industrial supplies is provider of Hyundai welding electrode low hydrogen E 7018 2.6mm for stick Welding Other Hyundai Welding Consumables, Flux Cored...₦5,213.75 -

Hyundai Welding electrode low hydrogen E 7018 3.2mm for stick Welding

Hyundai

₦5,213.75Hyundai Welding electrode low hydrogen E 7018 3.2mm for stick Welding GZ industrial supplies is provider of Hyundai welding electrode low hydrogen E 7018 3.2mm for stick Welding Other Hyundai Welding Consumables, Flux Cored Wire,...₦5,213.75 -

Hyundai Welding electrode low hydrogen E 7018 2.6mm for stick Welding

Hyundai

₦5,213.75Hyundai Welding electrode low hydrogen E 7018 2.6mm for stick Welding GZ industrial supplies is provider of Hyundai Welding electrode low hydrogen E 7018 2.6mm for stick Welding Other Hyundai Welding Consumables, Flux Cored Wire,...₦5,213.75