Floor Paint Maintenance: Industrial Equipment You Need

Introduction

Industrial floors endure constant wear and tear from heavy machinery, foot traffic, chemical spills, and environmental exposure. Maintaining industrial floor paint is essential to extend its lifespan, enhance workplace safety, and preserve aesthetics. Without regular maintenance, painted floors can peel, fade, or become hazardous, leading to costly repairs or workplace accidents.

This guide outlines the best industrial equipment for floor paint maintenance and essential best practices to keep your industrial floors in top condition.

Read more...Floor Paint Maintenance: How to Keep Your Floors Looking Their Best

Key Takeaway

-

Regular Maintenance Extends Lifespan – Routine cleaning, inspections, and touch-ups help prolong the durability of industrial floor paint.

-

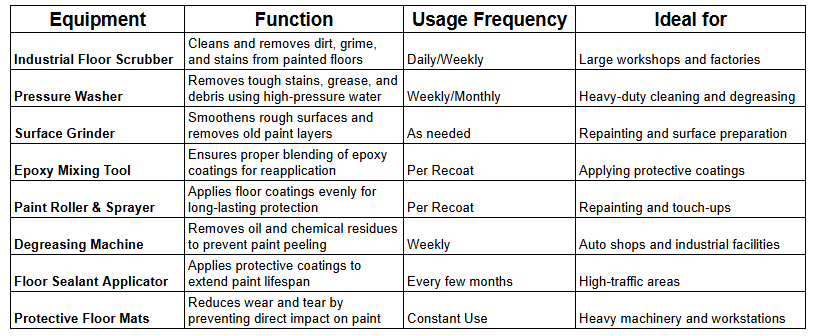

Essential Equipment is Key – Tools such as industrial floor scrubbers, pressure washers, surface grinders, and epoxy mixing tools ensure proper maintenance and reapplication.

-

Surface Preparation is Crucial – Before repainting, floors must be cleaned, degreased, and sanded to remove dirt and ensure strong adhesion.

Dongcheng Vacuum Cleaner 1200W/15L DVC15

Common Challenges in Industrial Floor Paint Maintenance

Industrial floor coatings are designed for durability, but various challenges can degrade them over time. Below are the most common issues and how they affect floor performance.

Wear and Tear from Heavy Traffic

Industrial facilities rely on forklifts, conveyor belts, and heavy machinery, all of which put significant pressure on floor coatings. Over time, painted surfaces can scratch, chip, or wear out, leading to:

- Uneven surfaces that pose safety risks.

- Degraded coatings that expose the underlying floor to damage.

- Increased maintenance costs if left unattended.

Chemical and Oil Spills

Many industrial environments, such as manufacturing plants and workshops, deal with hazardous chemicals, oils, and solvents that can:

- Break down protective coatings, causing discoloration and fading.

- Weaken the bond between paint and concrete, leading to peeling.

- Create slippery surfaces, increasing the risk of workplace accidents.

Moisture and Temperature Fluctuations

Industrial floors expand and contract due to changes in humidity and temperature. If floor coatings aren’t properly maintained, they may:

- Develop cracks and blisters, reducing durability.

- Allow moisture penetration, which leads to peeling and corrosion.

- Increase maintenance costs due to frequent recoating needs.

Solution: Using the right industrial cleaning and maintenance equipment helps prevent these issues and ensures that painted floors remain durable and slip-resistant.

Key Industrial Equipment for Effective Floor Paint Maintenance

Read more...How to Choose the Right Floor Paint: Tips for Durability and Aesthetics

Essential Industrial Equipment for Floor Paint Maintenance

To keep industrial floors in optimal condition, using high-performance cleaning, repair, and maintenance equipment is crucial.

Floor Cleaning Machines

Regular cleaning prevents dirt buildup, stain formation, and premature paint degradation. The following machines are essential for industrial floor maintenance:

Automatic Scrubbers:

- Ideal for large industrial spaces.

- Removes stubborn grime, oil, and debris.

- Uses rotating brushes and water-based cleaning solutions.

Industrial Sweepers:

- Best for removing dust, dirt, and loose particles.

- Helps prevent abrasive damage to floor coatings.

- Essential in factories, warehouses, and logistic centers.

Pressure Washers:

- Powerful cleaning for oil-stained and chemical-exposed floors.

- High-pressure water removes deep-set dirt without damaging the coating.

- Ideal for outdoor industrial spaces and heavily stained areas.

Ingco High Pressure Washer 2000W

Buffing and Polishing Machines

Purpose: Buffing and polishing restore the shine and protective coating on painted industrial floors.

Types:

- High-speed polishers for epoxy and polyurethane-coated floors.

- Orbital buffers for gentle maintenance of acrylic and water-based paints.

Benefits:

- Increases paint longevity by maintaining a smooth, sealed surface.

- Prevents floor discoloration and dullness over time.

- Enhances workplace aesthetics with a professional finish.

Floor Recoating and Repair Equipment

Over time, industrial floor coatings will develop cracks, chips, and surface wear, requiring periodic repairs and recoating. Below are key tools and equipment for maintaining and restoring painted floors:

Paint Applicators (Rollers, Sprayers):

- Used for touch-ups and full reapplications of industrial floor paint.

- Airless sprayers provide even coverage with minimal overspray.

- High-density rollers work well for epoxy and polyurethane coatings.

Epoxy Crack Fillers & Patching Compounds:

- Essential for repairing small cracks and chips before they spread.

- Prevents moisture infiltration, which can lead to paint peeling.

- Works on concrete, metal, and resin-coated floors.

Sanding Machines & Floor Grinders:

- Used to remove old, damaged paint layers before recoating.

- Helps smooth uneven surfaces and improves paint adhesion.

- Diamond grinders are ideal for concrete floor preparation.

Safety and Protective Gear for Floor Maintenance

Proper safety gear is essential when working with industrial cleaning chemicals, power tools, and floor coatings. Essential safety equipment includes:

PPE (Personal Protective Equipment):

- Chemical-resistant gloves to handle cleaning agents and paint removers.

- Safety goggles to protect eyes from dust, paint, and debris.

- Respirators or face masks when working with solvent-based coatings.

Wet Floor Signs and Barricades:

- Prevents accidents in areas undergoing cleaning or recoating.

- Essential for maintaining OSHA-compliant workplace safety standards.

DongCheng Polisher 750W 180MM DSP180

Best Practices for Industrial Floor Paint Maintenance

Establish a Routine Cleaning Schedule

- Sweep and scrub daily to prevent dirt accumulation.

- Perform weekly deep cleaning using industrial scrubbers.

- Recoat or touch up paint every 12-24 months based on usage.

Use the Right Cleaning Solutions

- Avoid harsh chemicals that can degrade paint over time.

- Choose pH-neutral cleaners for epoxy and polyurethane-coated floors.

- Use oil and grease removers specifically formulated for industrial settings.

Prevent Heavy Wear and Tear

- Install protective mats in high-impact areas.

- Use forklift tires with non-marking rubber to reduce scuff marks.

- Reapply protective topcoats to prolong the lifespan of painted surfaces.

Frequently Asked Questions

1. How often should industrial floors be repainted?

Industrial floors should be repainted every 3 to 5 years, depending on foot traffic, equipment movement, and exposure to chemicals. Regular maintenance and touch-ups can extend the lifespan.

2. What equipment is essential for maintaining industrial floor paint?

Key equipment includes industrial floor scrubbers, pressure washers, paint rollers, epoxy mixing tools, degreasers, and surface grinders for reapplication preparation.

3. How do I prevent peeling and cracking of floor paint?

Ensure proper surface preparation before painting, use high-quality industrial floor coatings, and apply sealants to enhance durability. Regular cleaning and avoiding harsh chemicals also help.

4. Can I apply new paint over an old floor coating?

Yes, but the surface must be thoroughly cleaned, sanded, or ground to remove loose paint and ensure proper adhesion of the new coating.

5. Where can I find reliable industrial floor maintenance equipment in Nigeria?

You can get high-quality floor maintenance tools and coatings from GZ Industrial Supplies. Visit GZ Industrial Supplies for premium floor maintenance solutions.

Related Articles

The Ultimate Guide to Preparing Your Floor for Painting with Floor Paint

Floor Paint Safety: Precautions to Take When Painting Your Floors

The Pros and Cons of Using Water-Based vs. Oil-Based Floor Paint

Conclusion

Maintaining industrial floor paint is crucial for safety, aesthetics, and longevity in high-traffic areas like welding and fabrication facilities. By using the right industrial equipment, such as scrubbers, sealers, and grinders, businesses can preserve floor coatings and prevent costly repairs.

For the best industrial floor maintenance equipment, including scrubbers, coatings, and cleaners, check outGZ Industrial Supplies. Get durable and reliable solutions tailored to your facility's needs today!