How to Load a Grease Gun Without a Mess

Introduction

When it comes to equipment maintenance, a grease gun is essential for ensuring your machinery runs smoothly. However, loading one especially without creating a sticky, slippery mess can be a challenge, particularly for first-time users. Whether you're in a workshop, on a construction site, or maintaining agricultural machinery, mastering this process will save you time, reduce waste, and keep your workspace clean

Grease guns are essential in industrial, mechanical, and automotive maintenance. However, improperly loading a grease gun can lead to wasted grease, tool malfunction, and unnecessary cleanup. This guide will walk you through a mess-free approach to loading your grease gun efficiently and safely.

Read more...Types of Grease to Use on a Grease Gun

Key Takeaway

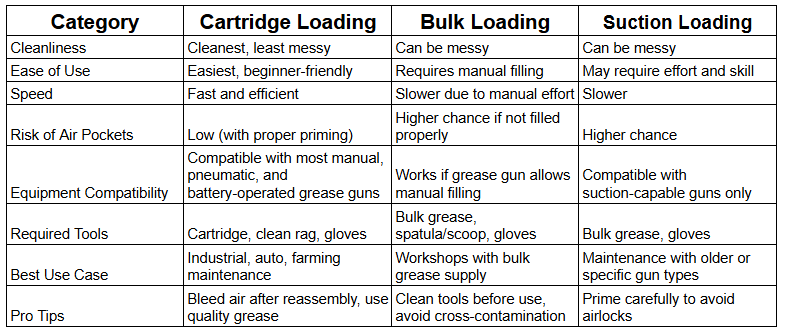

- Choose the Right Method: There are three common methods—cartridge loading, bulk loading, and suction loading. Cartridge loading is the cleanest and most user-friendly for most applications.

- Prepare Properly: Always clean the grease gun and your hands before loading to avoid contaminating the grease.

- Avoid Air Pockets: Bleed the air out of the gun after loading to prevent inconsistent grease flow or pressure buildup.

- Use Quality Grease: Only load clean, manufacturer-recommended grease that matches your equipment needs.

Tools You’ll Need

Before starting, gather the following:

- A grease gun (manual, pneumatic, or battery-operated)

- A cartridge of grease (make sure it’s compatible with your equipment)

- Clean rag or paper towels

- Protective gloves

- A flat work surface

Step-by-Step Guide: Loading a Grease Gun with a Cartridge

Step 1: Unscrew the Head from the Barrel

Start by unscrewing the grease gun head from the barrel. Hold the barrel firmly while turning the head counterclockwise. This will expose the plunger mechanism inside the barrel.

Step 2: Pull Back the Plunger Rod

Pull the T-handle or plunger rod all the way back until it locks into place. This action creates room in the barrel for the grease cartridge and ensures you won't spill grease during loading.

Step 3: Insert the Grease Cartridge

Remove the plastic cap from the new grease cartridge, then insert it into the barrel—open end first. Once inserted, remove the pull-tab seal from the exposed end of the cartridge.

Step 4: Reattach the Grease Gun Head

Screw the head of the grease gun back onto the barrel tightly. Ensure it's snug to prevent leakage but don’t overtighten, especially if your grease gun has a plastic or aluminum body.

Step 5: Release the Plunger and Prime the Gun

Once the head is reattached, unlock and slowly release the plunger rod back into the barrel. This will push grease toward the nozzle. Then:

- Pump the handle (for manual guns) or trigger (for electric/pneumatic models) several times to remove trapped air.

- If your grease gun has a bleed valve, open it slightly during priming to allow air to escape.

- Continue priming until grease starts to come out of the nozzle consistently without air pockets.

Pro Tip: If grease doesn’t flow smoothly, you may have an air lock. Re-tighten or slightly loosen the head and repeat the priming process.

Read more...Manual vs Pneumatic vs Battery-Powered Grease Guns: Which Is Best for You?

Comparison Table: Grease Gun Loading Methods and Grease Cartridge Types

Best Practices to Prevent Mess and Waste

To ensure a clean loading process every time, follow these tips:

- Always wear gloves – Grease is hard to clean off skin and fabrics.

- Use a rag under the barrel while inserting the cartridge to catch drips.

- Label your grease guns if using different types of lubricants to avoid cross-contamination.

- Clean the nozzle after each use to avoid hardened grease buildup.

- Store the gun upright to prevent leakage and air from entering the barrel.

Types of Grease Cartridges and Compatibility

Not all grease cartridges are created equal. Match your grease type with your equipment's manufacturer recommendations. Common types include:

- Lithium-based: Great for high-pressure and high-temp applications

- Calcium-based: Water-resistant; ideal for marine equipment

- Aluminum complex: Excellent for high-temp industrial settings

- Polyurea: Long-lasting, used in electric motors and sealed systems

If you're using the DongCheng Cordless Grease Gun – DCGG500, it's compatible with most standard cartridge types and allows quick, clean loading thanks to its pressure control system and 800mm hose for easier access to hard-to-reach fittings.

Read more...Common Grease Gun Problems and How to Fix Them

Safety Precautions When Handling Grease Guns

- Always wear gloves and eye protection.

- Keep the grease gun away from extreme heat or open flame.

- Avoid mixing different types of grease to maintain performance.

- Store the grease gun in a clean, dry place.

- Use only manufacturer-recommended grease for your equipment.

Frequently Asked Questions

1. Can I refill a grease gun without using a cartridge?

Yes, you can use bulk grease by scooping it directly into the barrel. However, it’s messier and may require extra effort to avoid air pockets.

2. Why is grease not coming out of my grease gun?

You may have an airlock. Re-prime the gun by loosening the head slightly and pumping until grease flows smoothly.

3. How do I know which grease to use?

Always consult your equipment manufacturer’s manual. Lithium-based grease is a good general-purpose option, but specialized machines may need calcium or polyurea types.

4. How often should I clean my grease gun?

Wipe down the exterior after every use and clean the nozzle regularly to prevent contamination and buildup.

Related Article:

Grease Guns in Nigeria: Complete Buyer’s Guide & Usage Tips

Importance of Lubricants for Machine Maintenance

Conclusion

Learning how to load a grease gun the right way saves you time, avoids waste, and ensures your equipment gets the lubrication it needs. Whether you're using a manual or cordless option like the DongCheng Cordless Grease Gun – DCGG500, the process can be clean and efficient if done properly.

Explore top-quality grease guns and compatible grease types today at GZ Industrial Supplies—your trusted source for industrial tools and maintenance solutions in Nigeria.