How to Use and Maintain Hydraulic Jacks for Safe Lifting

Introduction

Hydraulic jacks are among the most essential lifting tools in workshops, automotive garages, and even for personal vehicle owners. They use hydraulic pressure to raise heavy loads, making tasks such as changing tires, repairing undercarriages, and performing routine maintenance far easier and safer.

However, hydraulic jacks can also pose risks when not used properly. Every year, accidents occur because users rely solely on the jack without additional safety measures, overload the tool, or neglect basic maintenance. This highlights why safe operation and regular upkeep are critical.

This article provides a step-by-step guide on how to use hydraulic jacks correctly and maintain them for long-term reliability. Whether you’re a workshop owner, a roadside mechanic, or a DIY enthusiast, mastering these basics will improve both your safety and efficiency.

Key Takeaway

-

Proper Usage Prevents Accidents – Always follow manufacturer guidelines, use on stable surfaces, and never exceed the load capacity.

-

Routine Maintenance Ensures Longevity – Regular inspection, lubrication, and hydraulic fluid checks keep jacks in optimal condition.

-

Safety Protocols Are Non-Negotiable – Using jack stands, avoiding sudden load release, and proper storage minimize risks during lifting operations.

Understanding Hydraulic Jacks

What is a Hydraulic Jack?

A hydraulic jack is a mechanical device that uses hydraulic pressure to lift heavy objects. The principle behind its operation is Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. In practical terms, a small force applied on a piston handle is amplified to lift loads many times heavier than the operator’s input.

The main types of hydraulic jacks include:

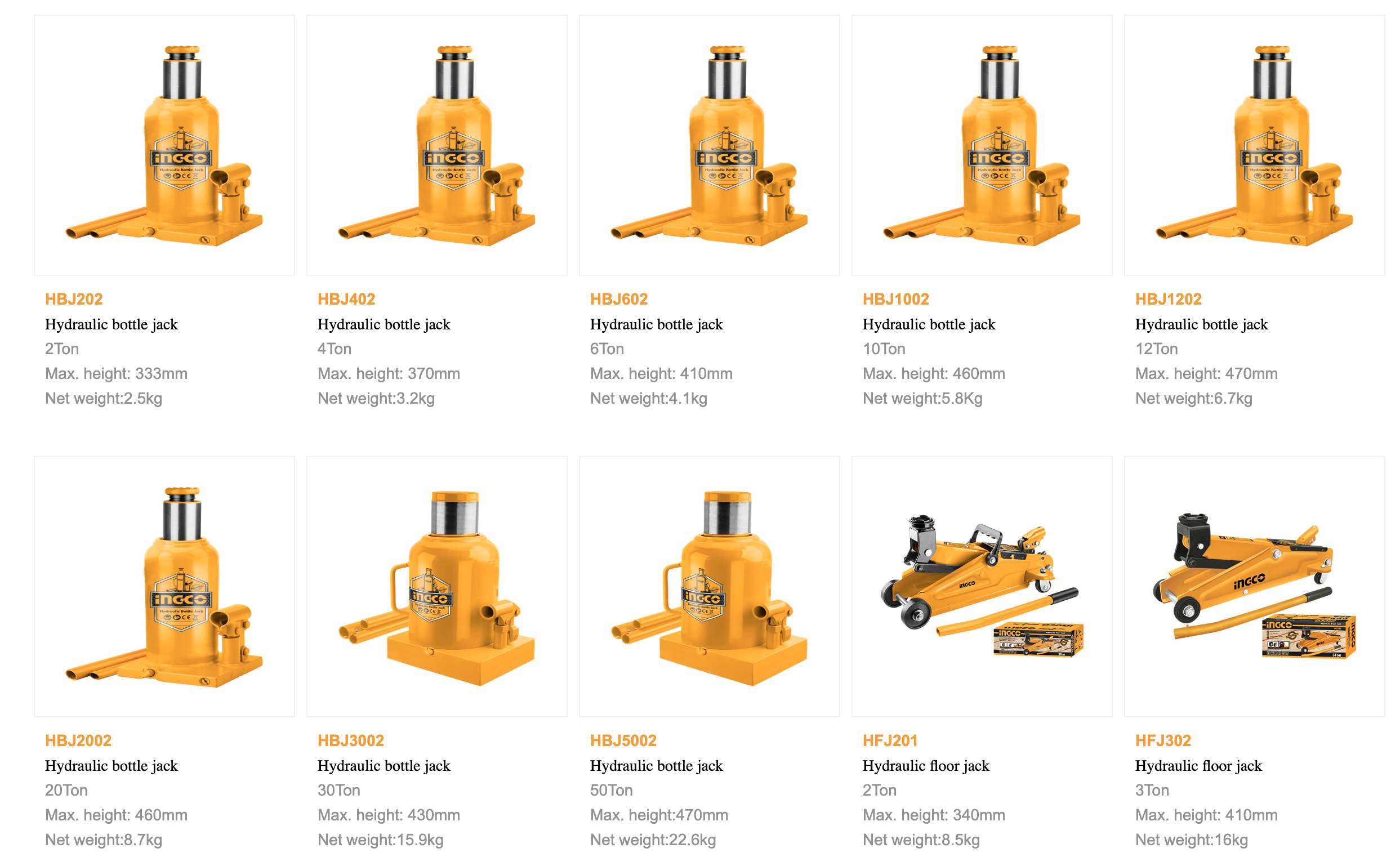

- Bottle Jacks: Compact, upright jacks shaped like bottles. They can lift very heavy loads but require sufficient clearance under the vehicle.

- Floor Jacks (Trolley Jacks): Larger, wheeled jacks that slide under vehicles. They are easy to maneuver and provide stable lifting, making them common in workshops.

- Scissor Jacks with Hydraulic Assist: A hybrid type often supplied with cars, combining screw mechanisms with hydraulic support for easier lifting.

Applications of Hydraulic Jacks

Hydraulic jacks are widely used across multiple industries and for personal applications:

- Automotive: Lifting cars, SUVs, and trucks for tire changes, underbody inspections, and repairs.

- Industrial Workshops: Supporting fabrication, machinery installation, and heavy-duty lifting tasks.

- Household/DIY: Handling small lifting tasks such as garden equipment or light trailers.

Their versatility makes them indispensable—but only when operated with proper safety precautions.

Safety Precautions Before Using a Hydraulic Jack

Before operating a hydraulic jack, it is important to prioritize safety. The following steps reduce the risk of accidents and equipment failure:

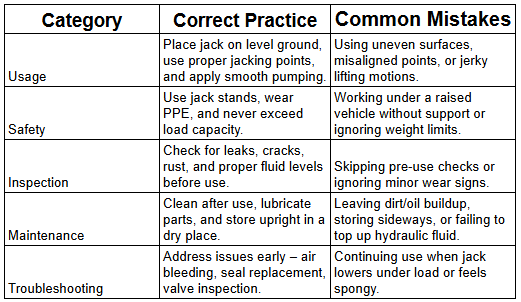

Inspect the Jack Before Use

- Check for oil leaks, cracks, rust, or bent handles.

- Confirm the jack is rated for the load you intend to lift.

Check the Ground Surface

- Always place the jack on flat, stable, non-slippery ground.

- Avoid soft soil or uneven surfaces that can cause the jack to tilt or sink.

Use Wheel Chocks and Jack Stands

- Wheel chocks prevent the vehicle from rolling during lifting.

- Jack stands provide solid support under the vehicle, ensuring that the jack is not the sole support mechanism.

Wear Appropriate PPE

- Heat- and slip-resistant gloves for grip.

- Steel-toe boots to protect feet from falling tools or parts.

- Goggles if working under the vehicle where dust or rust might fall.

Never Exceed the Rated Capacity

Hydraulic jacks are rated by tonnage (e.g., 2-ton, 5-ton, 20-ton). Overloading beyond the specified capacity can cause sudden failure.

By observing these precautions, you establish the foundation for safe lifting operations.

Step-by-Step Guide: How to Use a Hydraulic Jack Safely

Hydraulic jacks are straightforward to operate, but precision and care are required to ensure both safety and efficiency. Here’s a clear, step-by-step process:

Preparation

Before you begin lifting, take a few moments to prepare properly:

- Park on Flat Ground: Always ensure the vehicle or load is on a level, solid surface.

- Engage the Handbrake: Prevents rolling during lifting.

- Place Wheel Chocks: Block the wheels opposite to the lifting side. For example, if lifting the front, place chocks behind the rear tires.

A well-prepared setup minimizes the risk of sudden slips or imbalance.

Positioning the Jack

- Locate Jacking Points: Refer to the vehicle’s manual for manufacturer-recommended jacking points. These are reinforced sections designed to withstand lifting pressure.

- Avoid Weak Spots: Do not place the jack on thin metal, rusted frames, or unstable areas. Doing so can cause bending or collapse.

- Center the Jack Saddle: Align the lifting pad of the jack directly under the jacking point for maximum stability.

Operating the Jack

- Insert the Handle: Place the handle securely into the pump socket.

- Pump Slowly and Steadily: Apply smooth strokes until the load begins to rise.

- Lift Only as Necessary: Raise the vehicle just high enough to perform the required task—excess lifting increases instability.

Pro Tip: For vehicles, raise the wheel at least 2–3 inches off the ground for tire changes but avoid unnecessary elevation.

Securing the Load

This is the most important step for safety:

- Place Jack Stands: Slide jack stands under the vehicle’s frame or axle once the desired height is reached.

- Transfer Load to Stands: Gently lower the jack until the vehicle rests on the stands, ensuring stability.

- Keep the Jack in Place: Even after transferring the load, keep the hydraulic jack positioned as a backup.

Common Mistakes to Avoid

Even experienced operators sometimes overlook critical safety steps when using hydraulic jacks. These mistakes can lead to equipment damage, accidents, or serious injury. Below are the most common errors to avoid:

Relying on the Jack Alone

A hydraulic jack is meant for lifting, not for holding a load for extended periods. Depending solely on the jack without using jack stands is one of the leading causes of accidents in workshops and roadside repairs.

Overloading Beyond Capacity

Every jack has a specified weight rating (e.g., 2-ton, 5-ton, 20-ton). Exceeding this limit:

- Strains the hydraulic system.

- Increases the risk of sudden collapse.

- Can cause permanent damage to seals and cylinders.

Always match the jack’s capacity to the vehicle or load being lifted.

Using the Jack on Uneven or Soft Ground

Placing the jack on dirt, gravel, or an inclined surface compromises stability. On soft ground, the jack can sink under pressure. The correct practice is to:

- Use a flat, concrete, or asphalt surface.

- Place a steel plate or wooden block under the jack if the surface is questionable.

Ignoring Leaks or Damaged Parts

Hydraulic jacks rely on oil pressure. If you notice oil leaks, cracks in the housing, or a bent handle, do not ignore them. Continuing to use a faulty jack increases the chance of failure while under load

Lifting Higher Than Necessary

Some operators raise vehicles far higher than required, which reduces stability and increases wobble. Always lift just enough to complete the task, whether it’s a tire change or an underbody inspection.

By avoiding these common mistakes, operators ensure both personal safety and the long-term reliability of their hydraulic jacks.

How to Maintain Hydraulic Jacks for Longevity

Proper maintenance not only extends the lifespan of a hydraulic jack but also ensures safe and reliable performance every time it is used. A well-maintained jack reduces downtime, prevents accidents, and saves on costly replacements. Below are essential care practices:

Regular Cleaning

After each use, wipe down the jack to remove oil, grease, dust, and debris. Dirt buildup can enter moving parts, causing wear or jamming. Keeping the jack clean also makes it easier to spot leaks or cracks early.

Lubrication of Moving Parts

Hydraulic jacks have several pivot points and moving components that benefit from lubrication. Applying a light machine oil or grease to the wheels, hinges, and handle joints ensures smooth operation and prevents premature wear.

Hydraulic Fluid Maintenance

The hydraulic system depends on clean, sufficient fluid to function properly.

- Check Fluid Levels: Low oil levels reduce lifting power and can cause the jack to fail mid-lift.

- Top Up or Replace Oil: Always use the manufacturer-recommended hydraulic oil.

- Bleed Air from the System: If the jack feels “spongy” or fails to lift smoothly, trapped air may be the issue. This can be fixed by bleeding air according to the manual instructions.

Storage Practices

Improper storage can damage seals and reduce jack performance.

- Store the jack in a dry, upright position to prevent oil leakage.

- Avoid leaving it in areas with excessive heat, cold, or moisture.

- If storing long-term, lower the ram fully to reduce stress on internal seals.

Periodic Inspection and Servicing

Hydraulic jacks should be inspected routinely, especially in busy workshops.

- Check Seals and Pistons: Replace worn or cracked seals to prevent leaks.

- Inspect for Structural Damage: Bent handles, cracked bases, or warped saddles are signs it’s time for repair or replacement.

- Service Schedule: Heavy-use jacks in workshops should be serviced at least once a year; occasional-use jacks may need less frequent maintenance.

Troubleshooting Common Hydraulic Jack Issues

Even with proper use and maintenance, hydraulic jacks may sometimes fail to perform as expected. Understanding common problems — and their solutions — helps prevent downtime and ensures safety.

Jack Not Lifting to Full Height

Cause:

Low hydraulic oil, air trapped in the system, or worn seals.

Solution:

- Check and refill hydraulic oil to the recommended level.

- Bleed air from the jack (by opening the release valve slightly and pumping).

- Inspect seals; replace if leaking or damaged.

Jack Lowers Under Load

Cause: Faulty release valve, internal seal leaks, or worn piston.

Solution:

- Ensure the release valve is tightly closed.

- If the jack continues to sink, service or replace seals.

- In cases of severe leakage, professional repair or replacement may be required.

Handle Feels Too Soft or Spongy

Cause: Air trapped in the hydraulic system.

Solution: Bleed the jack to remove air. This usually restores normal pumping pressure.

Handle Feels Too Stiff

Cause: Rust, dirt buildup, or lack of lubrication.

Solution: Clean the moving parts and apply light machine oil or grease to hinges, wheels, and the pump mechanism.

Jack Will Not Lift at All

Cause: Severely low oil, blocked suction valve, or damaged cylinder.

Solution:

- Refill with the correct hydraulic oil.

- Clean or replace the suction valve.

- If the cylinder is damaged, consult a professional or replace the jack entirely.

Frequently Asked Questions

1. Can I use a hydraulic jack without jack stands?

No. Hydraulic jacks are designed for lifting, not holding loads long-term. Always use jack stands for safety.

2. How often should I change hydraulic fluid in my jack?

For frequent-use jacks, fluid should be checked every few months and replaced at least once a year or when contaminated.

3. What type of oil should be used in a hydraulic jack?

Always use manufacturer-recommended hydraulic jack oil. Substituting with motor oil or brake fluid can damage seals and reduce performance.

4. Why does my jack sink under load?

This usually indicates a faulty seal or release valve. Servicing or replacing seals will typically solve the problem.

5. Are hydraulic jacks safe for long-term lifting?

No. Jacks are not designed to hold loads for extended periods. For safety, use jack stands or other mechanical supports once the load is lifted.

Conclusion

Hydraulic jacks are invaluable tools for automotive repair, workshop operations, and heavy lifting tasks. But like any equipment, their safety and effectiveness depend on correct usage and proper maintenance.

By following safe operating steps, avoiding common mistakes, maintaining fluid levels, and addressing small issues early, you can ensure your jack remains reliable for years. Remember: never compromise on safety — always use jack stands, check for wear, and maintain your jack regularly.

For professionals and DIY enthusiasts in Nigeria and beyond, investing in genuine hydraulic jacks and consumables is a smart decision. Reliable suppliers not only provide quality products but also ensure after-sales support when needed.

Get premium hydraulic jacks and accessories from GZ Industrial Supplies your trusted source for durable lifting equipment in Nigeria.