Manual vs Pneumatic vs Battery-Powered Grease Guns: Which Is Best for You?

Introduction

When it comes to machine maintenance, proper lubrication is non-negotiable. Grease guns play a critical role in keeping equipment running smoothly, preventing friction, and extending the life of components. But with different types available manual, pneumatic (air-powered), and battery-powered how do you decide which is best for your needs?

In this guide, we compare the strengths and limitations of each type, helping you select the right tool for your environment, budget, and daily demands. Whether you’re a DIY mechanic, a farm operator, or a heavy-equipment technician, this comparison is for you.

Read more...Common Grease Gun Problems and How to Fix Them

Key Takeaway

- Manual grease guns are budget-friendly, easy to maintain, and suitable for occasional or light-duty tasks where mobility and simplicity are key.

- Pneumatic grease guns offer fast, continuous lubrication ideal for high-volume workshops but require access to a compressed air system.

- Battery-powered grease guns deliver superior pressure and portability, making them perfect for fieldwork, heavy-duty use, and reducing operator fatigue.

- Choosing the right grease gun depends on your work environment, lubrication frequency, mobility needs, and available power sources.

Understanding Grease Guns: A Quick Overview

A grease gun is a mechanical device designed to apply lubricant (typically grease) under pressure to specific points on machinery and equipment. It ensures that moving parts like bearings, joints, and gears remain protected from wear and tear. Grease guns are widely used across sectors including agriculture, automotive, manufacturing, and construction.

Choosing the right type of grease gun improves:

- Efficiency and ease of use

- Grease application accuracy

- Overall equipment uptime

Manual Grease Guns

How They Work

Manual grease guns are operated by hand, typically using a lever or pistol grip. You manually pump the handle to push grease through the nozzle and into the lubrication point.

Pros

- Cost-effective and readily available

- No power source required

- Lightweight and compact

- Simple to maintain

Cons

- Labor-intensive, especially for frequent use

- Inconsistent pressure and grease flow

- Slower output compared to powered options

Best For:

- Occasional lubrication tasks

- Light-duty maintenance work

- Remote job sites where power tools aren’t practical

Manual grease guns are ideal for hobbyists or operations with limited lubrication needs. They’re dependable, affordable, and perfect as a backup option even in high-volume environments.

Read More...Grease Couplers: Types, Uses and How to Choose

Pneumatic (Air-Powered) Grease Guns

How They Work

Pneumatic grease guns use compressed air to create pressure, pushing grease through the nozzle with minimal manual effort. They are connected to an air compressor and deliver consistent grease output through a trigger-operated mechanism.

Pros

- High-pressure, continuous grease delivery

- Less user fatigue for repetitive tasks

- Ideal for bulk lubrication jobs

Cons

- Requires access to a reliable air compressor

- Less portable—restricted by hose and compressor

- Initial setup cost is higher than manual types

Best For:

- Workshops and garages with central air systems

- High-frequency lubrication tasks

- Production environments with high throughput

Battery-Powered Grease Guns

How They Work

Battery-powered grease guns (also known as cordless grease guns) operate using rechargeable lithium-ion batteries. They automate the grease delivery process, combining the mobility of manual guns with the efficiency of pneumatic models—without the need for cords or compressors.

? Example: The DongCheng Cordless Grease Gun – DCGG500, available at GZ Industrial Supplies, is a prime example. With up to 10,000 PSI working pressure, a dual-speed oil injection system, and a portable 20V battery, it handles light and heavy-duty tasks with ease.

Pros

- Highly portable and convenient

- Fast grease delivery with minimal effort

- Great for both field and workshop use

- Ideal for greasing hard-to-reach components

Cons

- Higher upfront cost

- Dependent on battery charge

- Slightly heavier than manual models

Best For:

- Field service technicians

- Industrial maintenance engineers

- Equipment fleets needing regular service

Cordless grease guns are a game-changer for those managing multiple lubrication points or working in mobile environments.

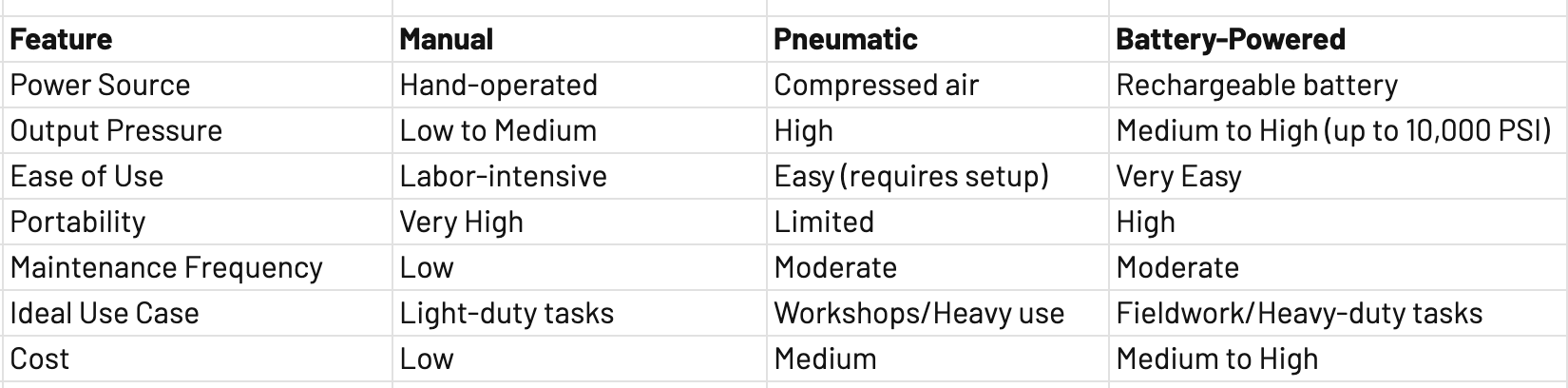

Side-by-Side Comparison Table

Which Grease Gun Is Right for You?

Choosing the right grease gun depends on your work environment, lubrication volume, and how often you perform maintenance. Here's a quick guide:

Choose Manual Grease Guns if:

- You're handling occasional, light-duty tasks

- Portability and low cost are top priorities

- You work in tight spaces without access to power or air

Choose Pneumatic Grease Guns if:

- You manage high-volume lubrication needs

- Your workshop is equipped with compressed air

- You want faster, consistent output with minimal hand strain

Choose Battery-Powered Grease Guns if:

- You need freedom from cords and hoses

- You perform regular or heavy-duty lubrication

- You want the best balance between power, convenience, and mobility

For Nigerian technicians and engineers working in industrial, construction, or fleet maintenance, the DongCheng Cordless Grease Gun – DCGG500 is a top-tier solution. Available now at GZ Industrial Supplies, it provides reliability, portability, and precision in every application.

Frequently Asked Questions

1. What is the main difference between manual, pneumatic, and battery-powered grease guns?

Manual grease guns are hand-operated and ideal for light tasks. Pneumatic grease guns use compressed air for continuous flow, while battery-powered models provide high pressure and portability without manual effort or air supply.

2. Which grease gun is best for field service technicians?

Battery-powered grease guns are the best choice for field service due to their portability, ease of use, and consistent output, especially in remote or outdoor locations where air compressors aren’t available.

3. Are pneumatic grease guns better than manual ones?

Yes, in high-volume workshop environments. Pneumatic grease guns offer faster and more consistent lubrication with less user fatigue. However, they require an air compressor and are less portable than manual grease guns.

4. How do I choose the right grease gun for my needs?

Consider your work environment, lubrication frequency, equipment size, and available power sources. For occasional use, go manual; for constant in-shop work, go pneumatic; for mobile and heavy-duty jobs, choose battery-powered.

5. Do battery-powered grease guns require a lot of maintenance?

Not necessarily. Just keep the battery charged, clean the tool regularly, and store it in a dry, dust-free place. Avoid overloading the grease cartridge or running the battery to zero for best performance.

Related Article

Types of Grease to Use on a Grease Gun

How to Load a Grease Gun Without a Mess

Conclusion

The right grease gun can drastically improve your maintenance routine, extend equipment life, and save you valuable time and effort. While manual grease guns are cost-effective for small jobs, pneumatic models deliver power for heavy workshops, and battery-powered grease guns offer the ultimate in flexibility and efficiency.

No matter your choice, using the correct type of grease and following safe greasing techniques is just as important as the tool itself.

Visit GZ Industrial Supplies for high-quality grease guns like the DongCheng Cordless Grease Gun – DCGG500, and consult our experts to find the perfect fit for your needs.