WHAT ARE HYDRAULIC HOSES USED FOR?

Introduction

Hydraulic hoses are the cornerstone of modern machinery. Found in nearly every industrial and mechanical environment, these durable, flexible tubes channel hydraulic fluid under high pressure to power complex systems and equipment. From lifting excavator buckets to powering robotic arms, hydraulic hoses serve as the arteries of heavy-duty applications.

In Nigeria’s rapidly expanding construction, oil & gas, agriculture, and manufacturing sectors, understanding the role and value of hydraulic hoses is key to ensuring operational efficiency, safety, and productivity. Whether you're a technician, site engineer, or procurement officer, knowing what hydraulic hoses do and where they apply is a strategic advantage.

From precise hydraulic controls in injection molding to fluid transfer in forklifts and aerial lifts, the Orientflex SAE100 R7 keeps operations running with zero leaks and maximum flexibility. Designed for tight spaces and tough cycles, it’s the quiet hero behind smooth, uninterrupted performance.

Key Takeaway

-

Essential for Fluid Power Transmission: Hydraulic hoses transport pressurized hydraulic fluid between components like pumps, valves, cylinders, and motors, enabling mechanical force and movement in heavy machinery.

-

Vital in Mobile and Industrial Equipment: Used in construction, agriculture, mining, manufacturing, and oil and gas sectors, hydraulic hoses power equipment such as excavators, forklifts, tractors, and cranes.

-

Support High-Pressure, High-Performance Systems: Hydraulic hoses are engineered to handle extreme pressure, temperature, and vibration—crucial for systems that require precision, force, and reliability.

In demanding workshops and on-site operations, the Orientflex SAE 100 R8 hose delivers reliable flow for hydraulic and pneumatic systems. Its aramid fibre reinforcement withstands extreme pressure, while the abrasion-resistant cover extends service life. Built for precision, it keeps critical equipment performing at its best.

What Is a Hydraulic Hose?

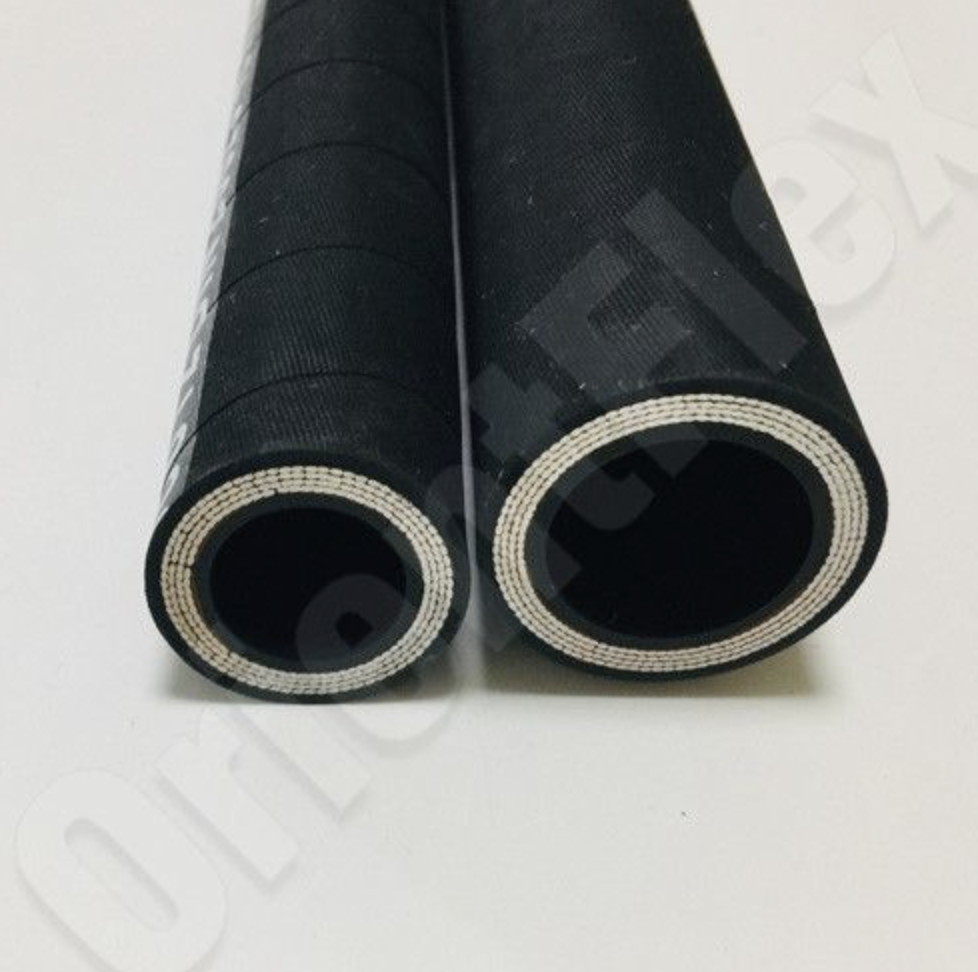

At its core, a hydraulic hose is a reinforced flexible tube used to convey hydraulic fluid between components within a hydraulic system. These hoses are typically constructed with multiple layers to withstand extreme pressure, temperature, and abrasion. The three main parts of a hydraulic hose include:

- Inner Tube – Carries the fluid and must be compatible with the type of hydraulic oil used.

- Reinforcement Layer – Made of braided or spiral-wound steel wire to handle pressure.

- Outer Cover – Protects the hose from external damage like abrasion, oil, weather, and chemicals.

Hydraulic hoses come in various sizes, pressure ratings, and material compositions depending on the application. They also feature specific types of end fittings and couplings to ensure compatibility with valves, cylinders, pumps, and other hydraulic components.

When hydraulic systems face extreme pressure and relentless cycles, the Orientflex EN856 4SP rises to the challenge. Built with four layers of high-tensile steel wire, it delivers strength, flexibility, and a million-cycle endurance. In the toughest industrial conditions, it keeps your operations flowing without compromise.

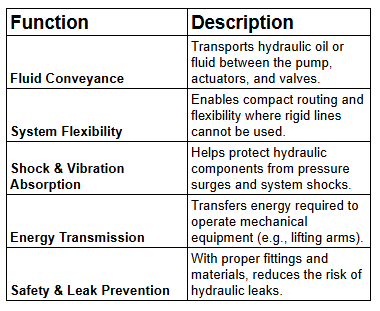

Core Functions of Hydraulic Hoses

Hydraulic hoses are not just fluid transfer lines. Their design allows them to perform several critical roles in hydraulic-powered machinery:

In Nigeria, where equipment is often subjected to rugged environments from offshore platforms to dusty mining sites having reliable hoses that fulfill these functions is crucial.

Common Applications of Hydraulic Hoses

Hydraulic hoses are essential across a broad spectrum of industries. Here are some of the most common and impactful uses:

Construction & Heavy Machinery

Hydraulic hoses power excavators, bulldozers, cranes, and backhoes. They control the movement of booms, buckets, and outriggers. In building projects from Lagos to Abuja, they’re vital to machine performance.

Agriculture

In Nigeria’s agricultural sector, hydraulic hoses are used in tractors, sprayers, and combine harvesters. Whether lifting plows or rotating tillers, they support planting and harvesting cycles year-round.

Manufacturing & Automation

Hydraulic hoses are found in hydraulic presses, injection molding machines, robotic arms, and conveyor systems. In factories producing everything from plastics to steel, these hoses are the backbone of automation.

Oil & Gas

Whether it's an offshore drilling rig near Bonny Island or a downstream terminal in Warri, hydraulic hoses operate key components like blowout preventers, pipe-handling equipment, and cranes. Their ability to function under extreme pressure and hazardous conditions makes them indispensable.

Mining and Quarrying

In mining operations, especially in regions like Jos, Enugu, or Ogun State, hydraulic hoses are essential in underground loaders, rock drills, crushers, and hydraulic shovels. These environments are harsh and demanding, so hoses must withstand abrasion, high pressure, and extreme temperatures. Whether conveying hydraulic oil to a jackhammer or powering a hydraulic lift deep underground, durability and reliability are key.

Marine and Shipbuilding

Hydraulic systems are widely used in ship steering gear, stabilizers, winches, cranes, and hatch covers. Marine-grade hydraulic hoses must be corrosion-resistant and capable of performing in wet, salty conditions. Epoxy Oilserv and other marine service providers across Nigeria frequently specify specialized hydraulic hoses for offshore platforms, supply vessels, and port equipment.

Built for the toughest hydraulic jobs, the Orientflex EN856 4SH thrives under extreme pressure and high impulse demands. With four layers of spiral steel wire and oil-resistant durability, it keeps industries moving when failure isn’t an option.

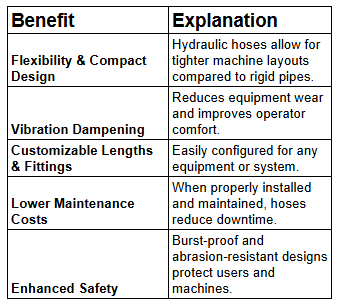

Benefits of Using Hydraulic Hoses

Beyond their essential functions, hydraulic hoses offer a range of benefits that contribute to the efficiency, safety, and cost-effectiveness of industrial operations:

This is particularly useful in Nigeria, where replacement parts may not always be readily available. A good hose can extend a machine’s working life significantly.

Choosing the Right Hydraulic Hose

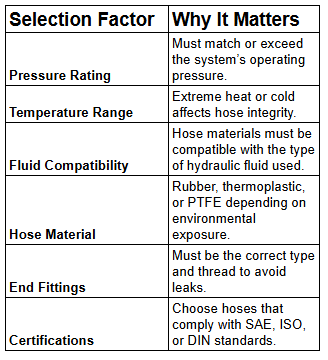

Choosing the right hydraulic hose is not just about size, it’s about the right fit for the job. The wrong hose can cause system inefficiencies, premature wear, and even safety hazards. Here’s what to consider:

Tip: Always work with verified vendors like GZ Industrial Supplies, Epoxy Oilserv, or Tikweld to ensure product authenticity and support.

For air brake systems, the Orientflex SAE 100 R5 acts as a flexible, high-pressure conduit that safely carries the compressed air (or sometimes hydraulic fluid in combination systems) from the compressor or control valves to the brake actuators.

Frequently Asked Questions (FAQs)

1. What type of fluid runs through hydraulic hoses?

Hydraulic hoses typically carry hydraulic oil, but can also convey water, fuel, synthetic fluids, and lubricants depending on the system requirements and hose material.

2. How long do hydraulic hoses last?

With proper use and regular maintenance, hydraulic hoses can last from 1 to 5 years. However, harsh environments or incorrect installation can reduce their lifespan.

3. Can I repair a hydraulic hose myself?

Temporary fixes like hose tape or clamps might work briefly, but for safety and reliability, professional replacement is recommended. Always test for leaks before reactivating the system.

4. How do I know when a hose needs replacement?

Signs include cracking, abrasion, leakage, reduced system performance, and swelling. A visual inspection and pressure test can confirm the need for replacement.

5. Where can I buy original hydraulic hoses in Nigeria?

Trusted suppliers include GZ Industrial Supplies, Epoxy Oilserv, and Tikweld Services, offering top brands and reliable after-sales support.

Conclusion

Hydraulic hoses are vital components in Nigeria’s most demanding industries from construction and agriculture to mining and marine. Their ability to handle high pressure, extreme temperatures, and rough handling makes them indispensable for safe and efficient operations.

Choosing the right hose type and supplier will save you time, money, and potentially catastrophic failure. As businesses continue to modernize and automate, the demand for reliable hydraulic systems will only grow.