Why Transformer Oil Quality Matters: Tips for Proper Use & Storage

Introduction

Transformer oil is the silent protector inside every high-voltage transformer. Beyond being just a fluid, it is the lifeblood of the transformer, keeping it cool, insulating live components, and preventing oxidation. In Nigeria’s growing power infrastructure, where transformers are essential for both urban and rural electricity distribution, oil quality is a major factor in ensuring uninterrupted supply and avoiding costly breakdowns.

Unfortunately, transformer oil is often overlooked until problems arise like overheating, voltage instability, or complete transformer failure. This guide explains why oil quality matters, the risks of poor maintenance, and proven tips for proper use and storage that will extend transformer life, reduce downtime, and save costs.

The Nynas Nytro 10XN Super Grade delivers exceptional oxidation stability, high dielectric strength, and superior heat transfer, ensuring longer transformer life with minimal maintenance. Follow proper storage and handling practices to preserve its performance and safeguard your electrical assets.

Key Takeaway

-

Transformer Oil is Critical for Reliability – It provides both insulation and cooling, preventing electrical faults and overheating in transformers.

-

Oil Quality Directly Affects Performance – Contaminated or degraded oil reduces dielectric strength, increases fire risk, and shortens transformer lifespan.

-

Regular Testing is Essential – Routine checks for moisture, acidity, and dielectric strength help detect early warning signs before major breakdowns occur.

-

Proper Storage Prevents Contamination – Always store transformer oil in sealed, moisture-free, and shaded environments to avoid water, dirt, and oxidation.

What is Transformer Oil?

Transformer oil, sometimes called insulating oil, is a specialized high-grade mineral or synthetic oil used in transformers, switchgear, and other high-voltage electrical equipment. Its main functions are:

- Insulation – Prevents electrical discharges between live components.

- Cooling – Transfers heat away from windings and the core.

- Protection – Prevents moisture and oxygen from degrading insulation and metals.

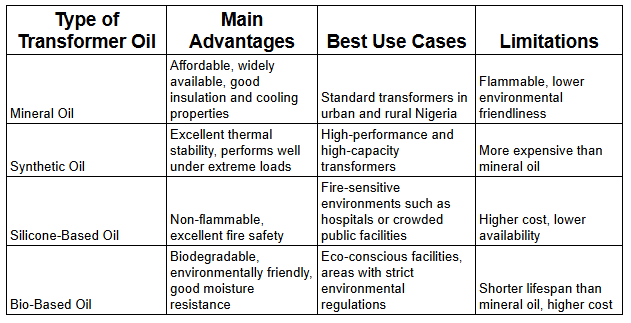

Types of Transformer Oil

- Mineral Oil – The most common and cost-effective, used in the majority of transformers in Nigeria.

- Synthetic Oil – Offers better thermal stability, ideal for high-performance systems.

- Silicone-Based Oil – Non-flammable, often used in fire-sensitive environments.

- Bio-Based Oil – Environmentally friendly alternative with good biodegradability.

Choosing the right type depends on the transformer’s design, operating environment, and safety requirements.

Why Transformer Oil Quality Matters

Electrical Performance

High-quality oil maintains high dielectric strength, which is the oil’s ability to resist electrical breakdown. If the dielectric strength is low, arcing and short circuits become more likely — a dangerous risk in high-voltage systems.

Thermal Stability

Transformers generate heat during operation. Poor-quality oil can lose its viscosity and cooling ability under high temperatures, leading to overheating and insulation damage.

Contamination Resistance

Good oil resists moisture, dust, and sludge formation. Contaminated oil conducts electricity poorly, accelerates corrosion, and clogs cooling ducts.

Equipment Longevity

Maintaining clean, high-quality oil reduces wear and tear on windings and insulation, extending the operational life of the transformer.

Prevention of Electrical Failures

Transformer failure due to oil breakdown can cause widespread blackouts and high repair costs. Regular testing and quality control prevent such disruptions.

Common Causes of Transformer Oil Degradation

Even the best oil degrades over time due to operational and environmental factors:

- Moisture Ingress – Water vapor from the atmosphere or faulty breathers reduces dielectric strength.

- Particulate Contamination – Dust, rust, or metallic particles cause insulation failure.

- Oxidation – Prolonged exposure to air causes acids and sludge to form.

- Thermal Stress – Overloads or poor cooling increase degradation speed.

- Electrical Discharges – Partial discharges or arcing within the transformer can carbonize the oil.

How to Test Transformer Oil Quality

Testing transformer oil isn’t just a preventive measure — it’s an essential maintenance routine for safe and reliable operations. In Nigeria, where environmental factors such as humidity, dust, and fluctuating power supply are common, regular testing is even more important.

Dielectric Breakdown Voltage (BDV) Test

- Purpose: Measures the oil’s insulating strength.

- Process: Apply increasing voltage across a gap in the oil until breakdown occurs.

- Ideal Value: A BDV of ≥ 30 kV is considered safe; anything lower indicates contamination or moisture ingress.

Dissolved Gas Analysis (DGA)

- Purpose: Detects gases formed from oil breakdown or electrical faults.

- Importance: Early detection of arcing, overheating, or insulation failure before catastrophic damage occurs.

Moisture Content Test

- Purpose: Measures water levels in the oil, as moisture drastically reduces insulation capacity.

- Ideal Value: Below 35 ppm for in-service mineral oil.

Interfacial Tension (IFT) Test

- Purpose: Determines oil’s resistance to sludge formation.

- Low IFT: Indicates oil oxidation and contamination.

Acidity Test (Neutralization Value)

- Purpose: Checks for acid buildup, which corrodes metal parts and damages insulation.

Proper Use Guidelines for Transformer Oil

Following correct usage procedures ensures transformer oil performs effectively and lasts longer.

Use the Right Oil for the Job

- Match the oil type to the transformer’s specifications.

- Avoid mixing different oil types unless they are proven compatible.

Maintain the Breather System

- Use silica gel breathers to prevent moisture ingress.

- Replace silica gel when it changes color from blue to pink (moisture-saturated).

Avoid Overloading Transformers

- Continuous overloading increases oil temperature and accelerates degradation.

Keep Oil Levels in Check

- Low oil levels reduce cooling efficiency and increase risk of insulation breakdown.

Use Clean, Dry Equipment for Oil Handling

- Always filter and dehydrate oil before filling the transformer.

- Avoid contact with dust, water, or metal shavings during oil transfer.

Comparison of Transformer Oil Types: Advantages, Applications, and Limitations

Best Storage Practices for Transformer Oil

Store in Clean, Sealed Containers

- Use drums or tanks made of mild steel or stainless steel with airtight seals.

- Never store in containers previously used for chemicals, lubricants, or fuel.

Keep Away from Moisture & Dust

- Store in dry, covered facilities away from rainwater, humid air, and dust contamination.

- Elevate drums from the ground to prevent corrosion.

Control Temperature & Sunlight Exposure

- Avoid prolonged exposure to direct sunlight, which accelerates oxidation.

- Maintain storage temperature between 10°C – 40°C where possible.

Label Clearly

- Mark each container with oil grade, batch number, and date of receipt.

- Helps track oil age and plan preventive replacement.

Challenges & Solutions in Nigeria

Power Fluctuations – Frequent outages and voltage spikes can accelerate oil degradation.

Solution: Conduct BDV tests quarterly and keep standby oil ready for top-up.

Dusty & Humid Environments – Construction zones, industrial hubs, and coastal areas increase contamination risks.

Solution: Invest in oil filtration systems and use silica gel breathers.

Long-Term Storage Issues – In many facilities, oil drums sit unused for years.

Solution: Test oil before use, even if it’s been sealed.

Frequently Asked Questions

1. How often should transformer oil be tested?

Every 6–12 months, or more frequently in high-load or harsh environments.

2. Can I mix different brands of transformer oil?

Only if they meet the same IEC/ASTM specifications and are confirmed compatible.

3. What’s the fastest way to remove moisture from oil?

Use a vacuum dehydration process before returning the oil to service.

4. Why does my transformer oil turn dark?

Aging, contamination, or overheating — indicating the need for testing and possible replacement.

5. Where can I buy certified transformer oil in Nigeria?

From trusted suppliers like GZ Supplies and Tikweld, who stock verified and tested oils.

Related articles

The Key Role of Transformer Oil in Ensuring Reliable Power Distribution

This article dives into proper storage and handling of transformer oil, safety considerations, and how contamination and electrical stress degrade oil quality. It's a natural fit to link readers who want practical advice on operational safety and environmental compliance.

Best Practices for Transformer Oil Storage and Handling to Ensure Long-Term Stability and Effectiveness

Ideal for operational managers, this guide lays out detailed steps for storing transformer oil safely, preserving its stability, and preventing contamination.

Choosing the Right Transformer Oil: A Guide to Specifications and Selection

This post helps readers understand critical oil properties like dielectric strength, thermal conductivity, and oxidation stability. It pairs well with your sections on why oil quality matters and can serve as an educational resource for deeper technical insight.

Conclusion

A clean, well-maintained industrial environment directly translates to improved productivity, reduced equipment wear, and a safer workplace. Epochem 502 Heavy Duty Degreaser stands out as a high-performance, eco-conscious choice for industries seeking dependable cleaning without compromising on environmental responsibility.

Whether you’re maintaining oilfield machinery, servicing automotive fleets, or keeping factory equipment in peak condition, Epochem 502 delivers results that keep your operations moving forward. With its biodegradable, non-flammable formula and proven versatility across multiple sectors, it’s the smart solution for businesses that value efficiency, safety, and sustainability.

Don’t compromise on equipment performance—order Epochem 502 today from GZ Industrial Supplies and experience the industrial cleaning solution trusted across Nigeria.