Workplace Safety and PPE Standards

Introduction

In any industrial environment be it oil and gas, manufacturing, construction, or logistics, workplace safety is not optional; it’s essential. Every year, thousands of preventable injuries occur because of poor hazard awareness or lack of proper safety measures. The ripple effects go beyond the injured worker, they affect productivity, company reputation, and even long-term profitability.

Workplace safety goes far beyond having warning signs and safety manuals. It’s about creating a culture where every team member takes responsibility for their environment. A safe workplace minimizes risks, boosts morale, reduces downtime, and ensures compliance with local and international safety laws.

In Nigeria, industrial operations, especially within oil and gas facilities, require strict adherence to Health, Safety, and Environment (HSE) standards. This ensures workers are protected from exposure to chemicals, mechanical hazards, and heavy machinery. When safety becomes part of the corporate culture, companies can achieve operational excellence and sustainability.

Key takeaway

-

Safety Starts With Awareness – Understanding workplace hazards is the first step toward preventing accidents, injuries, and costly downtime. Every employee must know the risks specific to their job environment.

-

PPE Is the Last Line of Defense – Personal Protective Equipment protects workers when engineering controls and administrative measures are not enough. Using the right PPE significantly reduces exposure to physical, chemical, and biological hazards.

-

Proper Selection Matters – Not all PPE is the same. Choosing the correct helmets, gloves, goggles, respirators, or safety boots depends on the specific risks present in the workplace.

-

Correct Use Determines Effectiveness – PPE must be worn, handled, and maintained properly. Even high-quality equipment will fail if used incorrectly or inconsistently.

To Explore safety equipment: Click here

Understanding PPE (Personal Protective Equipment)

Personal Protective Equipment (PPE) forms the last line of defense between workers and hazards. While administrative controls and engineering solutions can reduce risks, PPE provides personal protection against what cannot be fully eliminated.

Definition and Role

PPE refers to specialized clothing or equipment worn by employees to safeguard them from health and safety risks on the job. Whether handling chemicals, operating heavy machinery, or working in confined spaces, PPE helps prevent injuries and long-term health problems.

Categories of PPE

- Head Protection – Helmets and bump caps shield against falling objects, impact, or electrical shock.

- Eye and Face Protection – Goggles and visors protect from sparks, chemical splashes, or UV radiation during welding and grinding.

- Hearing Protection – Earplugs and earmuffs guard against high decibel noise in factories or drilling rigs.

- Respiratory Protection – Masks and respirators prevent inhalation of harmful gases, fumes, and dust.

- Hand Protection – Gloves provide insulation against cuts, chemicals, and high temperatures.

- Body Protection – Flame-resistant coveralls and aprons protect from heat, chemicals, or sharp objects.

- Foot Protection – Safety boots with steel toes and anti-slip soles prevent crush injuries and slips.

Importance of PPE Usage

Each PPE type is designed for specific tasks, meaning no single equipment can offer total protection. Proper training in PPE selection, use, and maintenance is critical to ensure effectiveness. Even the best safety gear can fail if not used correctly or replaced when worn out.

Common Workplace Hazards and How PPE Helps

Industrial worksites are full of potential hazards. Recognizing them early and selecting the right protective gear significantly reduces risks. Below are common hazards and how PPE mitigates them:

Chemical Hazards

Workers in oil and gas plants or manufacturing facilities are often exposed to acids, solvents, and cleaning agents.

PPE Solutions: Chemical-resistant gloves, face shields, respirators, and protective aprons reduce exposure and prevent burns or respiratory damage.

Mechanical Hazards

These involve contact with moving machinery, impact, or crushing injuries from tools and equipment.

PPE Solutions: Helmets, gloves, and reinforced boots prevent head and limb injuries, while flame-retardant clothing protects from sparks and heat.

Electrical Hazards

Electric shock and arc flashes can occur during maintenance or power distribution work.

PPE Solutions: Dielectric gloves, insulated boots, and non-conductive helmets reduce electrocution risks.

Biological Hazards

Exposure to bacteria, viruses, or biological waste can happen in waste management or chemical cleaning operations.

PPE Solutions: Disposable masks, coveralls, and gloves maintain hygiene and safety standards.

Noise Hazards

Prolonged exposure to loud equipment and machinery can cause permanent hearing damage.

PPE Solutions: Ear defenders and foam plugs maintain safe sound levels.

Dust and Fume Hazards

Dust from grinding or fumes from welding can cause lung irritation or long-term respiratory illness.

PPE Solutions: Proper ventilation systems and respirators protect workers’ airways from contamination.

Global and Nigerian PPE Standards

In every industrial sector, adherence to safety and PPE standards is not just a best practice—it’s a legal and moral obligation. These standards establish the minimum requirements for protecting workers against occupational hazards and ensuring the quality of personal protective equipment.

Global Standards and Certifications

- OSHA (Occupational Safety and Health Administration – USA)

Sets and enforces protective workplace safety standards. OSHA requires employers to assess hazards and provide certified PPE to workers.

Example: OSHA 1910.132 outlines PPE use for general industry, construction, and maritime operations. - ISO 45001 (Occupational Health & Safety Management Systems)

This global benchmark provides a framework for reducing workplace risks, enhancing safety culture, and improving employee well-being.

Companies that implement ISO 45001 demonstrate a proactive approach to health and safety management. - EN Standards (European Norms)

Commonly marked as “EN 166” for eye protection or “EN 20345” for safety boots, EN standards define performance testing and certification for PPE in Europe and other regions. - ANSI/ISEA Standards (U.S.)

These standards define design, testing, and labeling requirements for PPE such as helmets, gloves, and respirators.

Nigerian PPE and Workplace Safety Regulations

Nigeria enforces several safety frameworks aimed at ensuring workers are protected in industrial and construction environments.

- Factories Act (1990, Revised 2004)

Mandates employers to provide safe working conditions, proper ventilation, and personal protective equipment suitable for specific job risks. - National Environmental Standards and Regulations Enforcement Agency (NESREA)

Oversees workplace safety concerning environmental pollutants and chemical exposure. - Department of Petroleum Resources (DPR) / NUPRC HSE Framework

In the oil and gas sector, the DPR (now NUPRC) enforces compliance with HSE policies across drilling, refining, and logistics operations. Companies must demonstrate proper PPE use during audits and inspections. - Nigeria Social Insurance Trust Fund (NSITF)

Provides compensation for workplace injuries—making preventive safety practices critical to minimize incidents.

Why Compliance Matters

Adhering to both international and local PPE standards ensures that:

- Employees are safeguarded from occupational hazards.

- Companies avoid costly penalties or shutdowns from regulatory agencies.

- Productivity increases due to fewer accidents and downtime.

- Corporate reputation improves with a proven record of employee care.

GZ Industrial Supplies supplies PPE and safety solutions that meet ISO, EN, and OSHA standards, helping Nigerian industries maintain global-level compliance.

Implementing a Safety Culture

Having PPE and rules in place isn’t enough—safety must be a culture, not a checklist. A company’s safety culture determines how effectively it manages risks and prevents accidents.

Conduct Regular Risk Assessments

Safety begins with awareness. Employers must:

- Identify potential hazards in each work area.

- Evaluate risk severity and likelihood.

- Implement preventive measures and assign appropriate PPE.

Routine inspections should verify that workers are using the right equipment and following established protocols.

Train and Empower Employees

Employees should receive ongoing training on:

- Correct PPE selection and usage

- Emergency response and first aid

- Hazard communication and labeling (e.g., for chemicals)

- Safe operation of machinery and tools

A trained workforce is confident, compliant, and proactive in preventing accidents.

Involve Leadership and Supervisors

Safety starts at the top. Supervisors and managers must lead by example, wearing PPE, reporting hazards promptly, and rewarding compliance. When leaders demonstrate safety commitment, workers follow suit.

Encourage Open Reporting

Workers should feel safe to report unsafe conditions or near-misses without fear of punishment. Anonymous reporting systems can help identify recurring hazards.

Track and Review Performance

Maintaining safety logs and using Key Performance Indicators (KPIs) like “Lost Time Injury Frequency Rate (LTIFR)” helps companies measure and improve their safety performance.

GZ Industrial Supplies works with clients across Nigeria to strengthen safety cultures by supplying certified PPE, providing training resources, and supporting compliance audits.

Selecting the Right PPE for the Job

Selecting the correct PPE isn’t just about compliance — it’s about matching the protection level to the specific risk in the work environment. The wrong PPE can be just as dangerous as none at all.

Conduct a Hazard Assessment

Before purchasing or assigning PPE, conduct a comprehensive hazard assessment to:

- Identify all physical, chemical, and biological risks in each work area.

- Determine exposure levels (duration and frequency).

- Classify PPE by risk type — e.g., respiratory, chemical, electrical, or impact protection.

A welder, for example, requires flame-resistant gloves, face shields, and coveralls, while a lab technician may need chemical-resistant gloves and goggles.

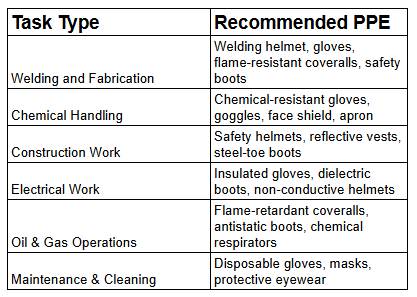

Match PPE to the Task

Each activity demands specialized equipment:

Selecting the right PPE ensures protection, comfort, and efficiency on the job.

Fit and Comfort

Proper fit is crucial. Ill-fitting PPE can cause discomfort, distraction, or even accidents. Adjustable straps, breathable fabrics, and ergonomic designs help workers perform better.

Employers should test-fit PPE before approval and offer multiple sizes to accommodate all users.

Compatibility

When workers need multiple PPE items, ensure they work together effectively. For instance, a respirator should not interfere with the seal of a face shield or helmet. Combining incompatible PPE may reduce protection.

Trusted PPE Suppliers

Using certified, high-quality PPE guarantees compliance and durability. GZ Industrial Supplies supplies a wide range of globally recognized brands — from chemical-resistant gloves and helmets to flame-retardant coveralls and industrial safety boots — all compliant with ISO, OSHA, and EN standards.

Maintenance and Storage of PPE

Even the best safety equipment can fail if it’s not properly maintained. Regular inspection, cleaning, and replacement are vital to ensure PPE performs as intended.

Cleaning and Decontamination

After every use, PPE must be cleaned according to manufacturer guidelines.

- Wash coveralls and gloves used with chemicals separately from regular laundry.

- Disinfect reusable masks and respirators to prevent contamination.

- Store goggles and face shields in protective cases to avoid scratches.

Proper cleaning extends PPE lifespan and maintains its protective qualities.

Inspection and Replacement

Before each use, inspect PPE for cracks, tears, corrosion, or other damage. Replace immediately if compromised.

Checklist for daily inspection:

- Helmet shell integrity

- Strap and buckle strength

- Lens clarity and cleanliness

- Glove wear and tear

- Boot sole and grip condition

Pro tip: Keep a maintenance log or barcode tracking system to monitor inspection intervals and replacement dates.

Proper Storage

Store PPE in cool, dry, and dust-free environments. Avoid sunlight exposure, which can degrade materials. For instance:

- Helmets should be stored upright to retain shape.

- Rubber gloves must be kept away from oils and solvents.

- Respirators should be stored in sealed containers when not in use.

Disposal of Worn-Out PPE

Old or contaminated PPE should be safely disposed of to prevent cross-contamination. For example:

- Burn contaminated fabrics in designated waste areas.

- Dispose of used masks and gloves in sealed containers.

- Follow environmental and safety guidelines for disposal, especially in chemical or oil-related industries.

Common Safety Violations and How to Avoid Them

Even the most safety-conscious organizations can fall short if daily practices are inconsistent. Recognizing frequent safety violations helps companies close gaps and prevent costly incidents.

Most Frequent Safety Violations

- Ignoring PPE Requirements

Workers often skip wearing safety gear due to discomfort or haste. This remains one of the top causes of workplace injuries. - Improper PPE Maintenance

Using worn-out gloves, faded helmets, or cracked visors compromises protection and violates safety regulations. - Lack of Hazard Communication

Employees unaware of chemical hazards or machinery dangers are more likely to cause or experience accidents. - Poor Housekeeping and Obstructed Work Areas

Spilled liquids, misplaced tools, and clutter increase the likelihood of trips, falls, and equipment damage. - Failure to Conduct Regular Safety Training

Safety procedures evolve. Without consistent training, even experienced workers can adopt unsafe shortcuts. - Incorrect PPE Selection

A mismatch between PPE type and hazard (e.g., using general gloves for chemical handling) reduces effectiveness.

How to Avoid These Violations

- Implement strict PPE policies with mandatory checks at entry points.

- Schedule regular safety training for all employees and contractors.

- Introduce a PPE tracking system to monitor usage and replacement cycles.

- Encourage reporting of unsafe conditions through anonymous feedback channels.

- Reward compliance — positive reinforcement boosts safety adherence.

GZ Industial Supplies supports partner industries by not only supplying certified PPE but also conducting HSE awareness sessions and safety audits to help teams remain compliant and protected.

GZ Industrial Supplies Commitment to Workplace Safety

At GZ Industrial Supplies, workplace safety isn’t just a policy, it’s a philosophy embedded in every operation. As one of Nigeria’s leading suppliers of industrial lubricants, cleaning agents, and safety equipment, the company understands that efficient production is only possible in a secure, well-protected environment.

Comprehensive Safety Solutions

GZ Industrial Supplies provides a full range of certified PPE and safety products, including:

- Industrial helmets, gloves, and face shields

- Chemical-resistant coveralls and aprons

- Anti-slip safety boots

- Respiratory and eye protection gear

- Spill control and emergency response kits

These products meet ISO, OSHA, and EN safety standards, ensuring maximum protection in harsh industrial settings.

Training and Technical Support

Beyond product supply, GZ Industrial Supplies collaborates with clients to develop:

- Customized HSE training programs for staff and contractors

- Safety audits and compliance checks for factories and oilfield operations

- Consultation on PPE selection based on job risk assessment

This holistic approach ensures organizations not only buy PPE but use it effectively and sustainably.

Partnership for a Safer Future

GZ Industrial Supplies vision extends to building a nationwide safety culture in Nigeria’s industrial and oil & gas sectors.

By prioritizing protection, awareness, and continuous improvement, the company empowers teams to work smarter and safer — today and for years to come.

Frequently asked questions

1. What is the most important PPE in an industrial setting?

There’s no single “most important” PPE, it depends on the job. For example, a welder’s top PPE includes a helmet and gloves, while a lab technician’s priority is chemical-resistant gear.

2. How often should PPE be replaced?

This varies by material and exposure. Helmets typically last 2–3 years, gloves and boots 6–12 months, and respirators as needed depending on contamination and filter use.

3. What does OSHA recommend for PPE use?

OSHA requires employers to assess workplace hazards, provide appropriate PPE, train employees, and ensure all equipment is properly maintained and replaced when defective.

4. Why choose GZ Industrial supplies for PPE and safety supplies?

GZ offers certified, globally compliant products tailored for Nigeria’s industrial and oilfield environments backed by expert support and nationwide delivery.

Conclusion

Workplace safety goes far beyond regulatory compliance—it's a strategic investment in protecting lives, improving productivity, and strengthening an organization’s reputation. Companies that commit to proper PPE usage and cultivate a strong safety culture benefit from fewer accidents, reduced operational costs, and a more confident, motivated workforce.

GZ Industrial Supplies remains a trusted partner in promoting this safety-driven future, providing certified, reliable PPE that meets the highest industry standards.

Protect your workforce today with high-quality safety gear from GZ Industrial Supplies.

Call: +234 805 339 0129

Email: sales@gz-supplies.com