When Your Company needs an Industrial Epoxy Coating

Introduction

Is your current flooring holding your business back? In demanding industrial and commercial environments, your floor isn't just a surface; it's a critical part of your operation. Constant repairs, safety hazards, or even a perpetually dusty environment can silently drain your resources and undermine your professionalism. If you're facing these challenges, it might be time to consider a strategic upgrade: an industrial epoxy coating.

This isn't just about aesthetics; it's about investing in a foundation that can withstand the rigors of heavy machinery, chemical spills, constant traffic, and much more. This guide will help you identify the clear signs that your business needs an epoxy coating, explore the immense benefits it offers, and understand why it's a smart, long-term investment for your facility here in Port Harcourt and beyond.

Key Takeaway:

-

Industrial epoxy coatings are a strategic investment, not just a repair, essential when your current flooring shows signs of failure like dusting, cracking, or chemical damage.

-

They provide unmatched durability, superior chemical resistance, enhanced safety, and easier maintenance, significantly extending floor lifespan and reducing long-term costs.

-

Choosing a professional for proper installation and the right epoxy type is crucial to ensure your facility gets a high-performance foundation that supports its operational demands and boosts its professional image.

What Exactly is an Industrial Epoxy Coating?

At its core, an industrial epoxy coating is a high-performance flooring solution created by mixing a resin with a hardener. This chemical reaction forms a rigid, durable plastic material that bonds incredibly strongly to concrete substrates. Unlike standard paints, which simply sit on the surface, epoxy coatings penetrate and become an integral part of your floor, creating a seamless, non-porous layer.

What sets industrial epoxy apart from residential or thinner "epoxy paints" is its formulation. Industrial-grade epoxies are designed to handle extreme conditions, offering superior resistance to abrasion, impact, chemicals, and heat. They are typically applied in thicker layers, providing a much more robust and long-lasting finish essential for heavy-duty environments

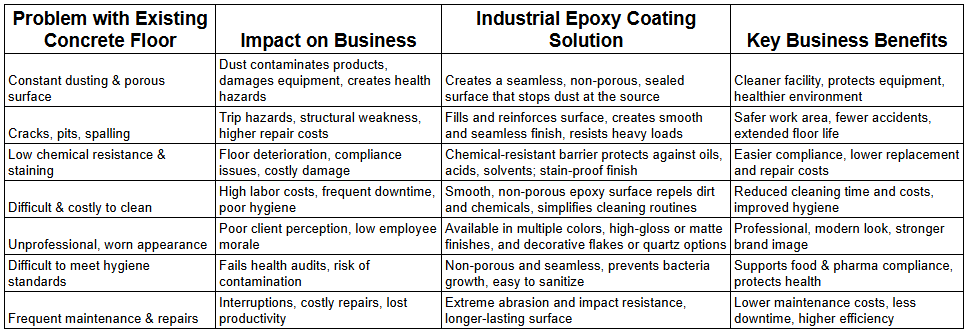

The Signs: When Your Current Flooring is Failing Your Business

Your floor communicates a lot about your operation, and often, it's the first place signs of inefficiency or potential hazards appear. Here are the clear indicators that your current flooring is no longer meeting your business's demands and that an industrial epoxy coating is needed:

Constant Concrete Dusting

If you're constantly cleaning up concrete dust, even after sweeping or mopping, your floor is literally deteriorating. This dust doesn't just make your facility look unkempt; it can contaminate products, damage sensitive equipment, and pose a respiratory health hazard to your employees. An epoxy coating seals the concrete, eliminating dust at the source.

Cracks, Pitting, and Spalling

Visible cracks, small pits, or larger areas where the concrete surface is flaking off (spalling) are more than just cosmetic issues. They indicate structural weakness, create uneven surfaces that are tripping hazards, and can allow moisture and contaminants to penetrate deeper, leading to more extensive damage over time. These are clear signs your floor can't handle the stress it's under.

Poor Chemical Resistance

In many industrial settings, spills are inevitable. If your concrete floor is easily stained or actively eroding from contact with oils, acids, solvents, or other chemicals, it's a serious problem. Not only does it look bad, but it compromises the integrity of the floor and can even lead to environmental or safety violations. Industrial epoxy is engineered to resist a wide range of corrosive substances.

High Maintenance & Cleaning Costs

Are you spending too much time and money patching holes, scrubbing stubborn stains, or dealing with a perpetually dirty appearance? Porous concrete floors trap dirt, grease, and grime, making them incredibly difficult and expensive to clean effectively. A seamless, non-porous epoxy surface makes cleaning a breeze, significantly reducing labor and material costs.

Safety Hazards

A slippery floor, especially when wet or oily, is a major liability. Uneven surfaces from damaged concrete also contribute to slips, trips, and falls, leading to potential employee injuries, lost work time, and insurance claims. Industrial epoxy can be formulated with anti-slip additives to create a safer work environment, even in high-traffic or wet areas.

Lack of Aesthetics/Professionalism

While functionality is key, the appearance of your facility also matters. A worn, stained, or damaged floor can negatively impact client perceptions, lower employee morale, and simply make your workspace feel less professional. A clean, bright, and uniform epoxy floor instantly elevates the look and feel of your entire operation, reflecting positively on your brand.

Regulatory Compliance Issues

Industries like food and beverage, pharmaceuticals, and healthcare have strict hygiene and safety regulations. A porous, damaged floor can make it impossible to meet these standards, as it harbors bacteria and contaminants. Epoxy coatings provide a seamless, easy-to-sanitize surface that helps companies comply with health, safety, and environmental mandates.

Why Industrial Epoxy Coatings Are a Smart Investment

Once you recognize the signs that your current flooring is falling short, it's time to understand why an industrial epoxy coating isn't just a repair, but a powerful upgrade that delivers significant long-term value to your business.

Durability & Longevity

This is where industrial epoxy truly shines. Unlike conventional flooring, epoxy is engineered to withstand the most punishing environments. It offers:

- Extreme Abrasion and Impact Resistance: Think about the constant traffic from forklifts, pallet jacks, and heavy machinery in a warehouse or manufacturing plant. Epoxy coatings are incredibly tough, resisting wear, scratches, and impact damage that would quickly break down other surfaces. This significantly extends your floor's lifespan, slashing future replacement and repair costs.

- Reduced Wear and Tear: Your investment means fewer disruptions from damaged flooring, keeping your operations smooth and efficient for years to come.

Chemical & Stain Resistance

Spills are an everyday reality in many industrial settings. Whether it's oil, grease, acids, alkalis, or aggressive solvents, these substances can quickly degrade unprotected concrete.

- Chemical Barrier: Epoxy creates a seamless, non-porous barrier that prevents these harsh chemicals from penetrating and damaging the substrate. This makes it an ideal solution for laboratories, auto repair shops, chemical processing plants, and any facility dealing with potential spills.

- Stain-Proof Surface: Beyond chemical attacks, epoxy resists staining from common industrial contaminants, ensuring your floor maintains a cleaner, more professional appearance.

Enhanced Safety Features

Safety is paramount in any workplace, and your floor plays a crucial role. Industrial epoxy coatings can be customized to significantly reduce workplace hazards:

- Seamless, Non-Slip Options: Unlike tiled floors with grout lines or standard concrete that can become slick when wet, epoxy can be applied seamlessly, eliminating trip hazards. We can also incorporate anti-slip aggregates directly into the coating, providing superior traction even in wet or oily conditions, which is vital for preventing slips, trips, and falls.

- Improved Visibility with Custom Markings: Epoxy comes in a wide range of colors. This allows for clear demarcation of walkways, safety zones, forklift lanes, and even hazard warnings directly on the floor, vastly improving operational safety and traffic flow.

Hygiene & Ease of Cleaning

For industries where cleanliness is critical, such as food and beverage processing, pharmaceuticals, or healthcare, an epoxy floor is indispensable.

- Non-Porous Surface: Concrete is inherently porous, acting like a sponge that traps dirt, bacteria, and contaminants. Epoxy creates a smooth, non-porous surface that prevents the absorption of liquids and microbial growth, making it incredibly hygienic.

- Effortless Cleaning: Spills and dirt simply sit on the surface, allowing for quick and easy cleaning with standard industrial cleaning equipment. This drastically reduces cleaning time, labor costs, and the use of harsh cleaning chemicals, contributing to a healthier and more efficient work environment.

Aesthetic Appeal & Professionalism

While durability is key, the look and feel of your facility significantly impact client perception and employee morale.

- Transformative Appearance: Forget dull, dusty grey concrete. Industrial epoxy coatings are available in a vast array of colors, finishes (from high gloss to satin or matte), and even decorative options like flake systems. This allows you to transform a drab, uninviting space into a bright, professional, and visually appealing environment.

- Reflects on Your Brand: A clean, well-maintained, and visually appealing floor sends a strong message of professionalism and attention to detail to clients, visitors, and employees alike.

Cost-Effectiveness & ROI (Return on Investment)

While the initial investment in an industrial epoxy coating might seem significant, its long-term cost benefits make it an exceptionally smart financial decision.

- Lower Long-Term Maintenance and Repair Expenses: Because epoxy floors are so durable and easy to clean, you'll spend far less on ongoing maintenance, patching, and eventual floor replacement compared to less robust flooring options.

- Reduced Operational Downtime: Fewer floor-related issues mean less need to halt operations for repairs, directly saving your business money from lost productivity.

- Increased Property Value: A high-quality, durable floor is a valuable asset that enhances the overall value and appeal of your commercial or industrial property.

Industrial Flooring Comparison: Concrete vs Industrial Epoxy Coating

Key Considerations When Choosing an Industrial Epoxy Coating

Investing in an industrial epoxy coating is a significant decision for your business, and making the right choices will ensure maximum longevity and performance. Here's what you need to consider:

Type of Epoxy

Not all epoxy coatings are the same. There are various formulations designed for specific needs:

- 100% Solids Epoxy: Highly durable and chemical resistant, offering the thickest, longest-lasting finish.

- Self-Leveling Epoxy: Ideal for creating a perfectly smooth, seamless surface, often used where aesthetics and easy cleaning are paramount.

- Flake or Quartz Systems: Incorporate decorative flakes or quartz aggregates for enhanced aesthetics and superior slip resistance.

- Chemical Resistant Epoxy: Specifically formulated to withstand the harshest acids, solvents, and other corrosive agents. Your chosen epoxy type should directly match your facility's operational demands.

Surface Preparation is Paramount

This is arguably the most critical step. Even the highest quality epoxy will fail prematurely if applied to an improperly prepared surface. This involves:

- Cleaning: Thorough removal of all dirt, grease, oil, and contaminants.

- Repair: Filling cracks, patching holes, and leveling uneven areas.

- Profiling: Mechanically abrading the concrete (e.g., grinding or shot blasting) to create a porous surface that the epoxy can deeply adhere to. Skipping this step leads to delamination and costly failures.

Professional Installation is Essential

While DIY kits exist for small residential projects, industrial epoxy coating is not a DIY job. The complexity of proper surface preparation, precise mixing ratios, rapid curing times, and specialized application techniques demand professional expertise. An experienced contractor ensures:

- Correct product selection and application.

- Optimal adhesion and longevity.

- Compliance with safety standards during installation.

- A durable finish that truly meets industrial demands.

Curing Time & Operational Downtime

Industrial epoxy coatings require specific curing times before they can be subjected to full traffic or heavy loads. This varies by product and temperature. Planning for this downtime is crucial to minimize disruption to your operations. A professional installer can help you schedule the project strategically, perhaps during off-hours or phased installations, to ensure a smooth transition.

Maintenance Requirements

While industrial epoxy floors are incredibly durable and easy to clean, they still benefit from proper maintenance to maximize their lifespan. This typically involves:

- Regular sweeping or vacuuming to remove abrasive debris.

- Mopping with a neutral cleaner.

- Prompt cleanup of spills. Avoiding harsh abrasive cleaners or equipment that could scratch the surface will keep your floor looking and performing its best for years.

Warranty & Aftercare

When selecting a service provider, inquire about their warranty for materials and workmanship. A reputable company will stand behind their work. Also, ask about aftercare advice and support to ensure you can maintain your new floor effectively.

Your Partner in Durable Flooring: Why GZ Industrial Supplies is the Right Choice

Here in Port Harcourt, where industrial demands are high, partnering with the right experts for your epoxy flooring project makes all the difference. At [Your Company Name], we bring extensive experience in delivering high-performance industrial epoxy coating solutions across various sectors, including manufacturing, oil and gas, automotive, and more.

We pride ourselves on our meticulous approach to surface preparation, precision application techniques, and unwavering commitment to quality and safety. We understand the unique challenges faced by businesses in this region and are dedicated to providing flooring solutions that not only meet but exceed your operational requirements. From initial consultation to project completion, your satisfaction and the longevity of your investment are our top priorities.

Related Articles

Epoxy Floor Coating for Food and Beverage Industry

HOW TO EXTEND THE LIFE OF YOUR EPOXY FLOOR

Conclusion

Your industrial floor is more than just a surface; it's a critical asset that supports your operations, protects your investments, and contributes to the overall safety and efficiency of your facility. When your concrete floor shows signs of wear, dusting, chemical damage, or presents safety hazards, it's a clear signal that your company needs an industrial epoxy coating.

By making this strategic investment, you're choosing unparalleled durability, superior chemical resistance, enhanced safety, and effortless maintenance. You're not just getting a new floor; you're future-proofing your facility, reducing long-term costs, and elevating the professional image of your entire business.

Ready to transform your industrial space with a high-performance flooring solution? Contact us today for a free consultation and let us help you build a stronger foundation for your business.