Hydraulic Hose Crimping Machines: DX68 vs Portable Units (Buyer’s Guide 2025)

Introduction

Hydraulic hose crimping is one of the most critical processes in industries like oil and gas, construction, mining, and manufacturing. These hoses carry high-pressure fluids that keep equipment running smoothly, and a poor crimp can lead to leaks, equipment damage, or even dangerous accidents. That’s why the choice of crimping machine is more than just a purchase, it’s an investment in safety, reliability, and productivity.

Among the most popular machines in the market are the Kaida DX68, a heavy-duty hydraulic crimper widely used in workshops, and portable crimping units, designed for on-site flexibility and quick repairs. Each has its own advantages and limitations. This guide compares them side by side, helping buyers in 2025 make the best decision depending on their industry, workload, and budget.

Key Takeaway

-

Power & Capacity: The DX68 series offers very high crimping forces (≈ 400-600 tonnes) and crimp range from about 6-51 mm, making them ideal for heavy, industrial applications. Portable units, by contrast, have much lower crimping force and smaller size ranges, sufficient for light repairs and field use.

-

Size, Weight & Portability: DX68 machines are large, heavy (≈ 240-260 kg), and stationary, suited for workshop/factory use. Portable crimpers are lightweight, smaller, easier to transport to different job sites. This flexibility makes them valuable for mobile technicians.

-

Speed & Efficiency: DX68 machines offer high work throughput (≈ 200 pieces/h in optimal conditions) with wide range dies (10 sets) and precision (accuracy ±0.01-0.02mm), well-suited for high-volume operations. Portable crimpers tend to be slower and more manual, but provide essential turnaround in field repairs.

What is a Hydraulic Hose Crimping Machine?

A hydraulic hose crimping machine is a specialized tool used to attach fittings to the ends of hydraulic hoses, creating a secure, leak-proof connection. The process involves compressing a metal ferrule around the hose and fitting under high pressure, ensuring the joint can withstand demanding conditions.

Without a proper crimp, hoses may fail prematurely, causing downtime and safety hazards. That’s why companies in Nigeria and worldwide rely on these machines to ensure precision and compliance with international hydraulic standards.

Different types of crimping machines exist, including manual, semi-automatic, and fully hydraulic units. In this guide, we’ll focus on comparing the Kaida DX68 hydraulic crimping machine (a workshop-grade solution) with portable hose crimpers (field-ready solutions).

Overview of the Kaida DX68 Hose Crimping Machine

The Kaida DX68 has earned a strong reputation in oil & gas, construction, and heavy industries due to its durability and precision. Built for continuous workshop use, the DX68 handles a wide range of hose diameters and is designed for high-volume crimping operations.

Key Features of the DX68:

- Powerful crimping force suitable for large-diameter, high-pressure hoses.

- Stable hydraulic system that ensures consistent, uniform crimps.

- Wide crimping range, accommodating various hose and fitting sizes.

- Long-lasting design with robust steel construction.

- Typically powered by electricity, requiring a fixed workshop setup.

Strengths: The DX68 is ideal for industries where reliability and throughput are critical. It delivers precise crimps every time, reducing downtime and extending hose life.

Limitations: Its size and fixed power requirements mean it is less suited for on-site fieldwork. It also comes with a higher upfront investment compared to portable units.

Overview of Portable Hose Crimping Machines

While the Kaida DX68 is built for heavy-duty, workshop-based operations, portable hose crimping machines are designed for mobility and convenience. These units are smaller, lighter, and easier to transport, making them indispensable for technicians who perform on-site maintenance or emergency repairs.

Key Features of Portable Units:

- Compact and lightweight design for easy transport.

- Can be manually operated or powered by smaller electric/hydraulic pumps.

- Suitable for medium to small hose diameters, commonly used in field repairs.

- Quick setup and operation, allowing technicians to resolve issues without hauling equipment back to the workshop.

Strengths: Portable units excel in situations where downtime is costly, and immediate action is required. They are widely used in construction sites, remote oil rigs, agricultural equipment servicing, and mobile repair operations. Their lower cost compared to large crimpers also makes them accessible to small businesses.

Limitations: These machines cannot match the crimping force, precision, or capacity of workshop-based units like the DX68. They may struggle with large-diameter or ultra-high-pressure hoses and generally have a shorter service life under heavy use.

Bottom Line: Portable crimping machines are best for field flexibility and budget-conscious buyers, while the DX68 is better for high-volume, heavy-duty operations.

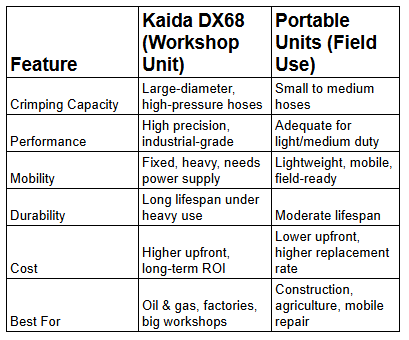

Comparative Analysis – DX68 vs Portable Units

Choosing between the Kaida DX68 and portable crimping machines depends on performance needs, budget, and where the machine will be used. Here’s how they stack up across key factors:

Performance

- DX68: Provides high crimping force, accommodating large-diameter and high-pressure hoses. Delivers consistent results suitable for industrial-scale operations.

- Portable Units: Effective for small to medium hoses but limited in crimping range and force. Best for light to medium-duty applications.

Mobility

- DX68: Fixed installation, heavy, requires electricity and stable workshop setup.

- Portable Units: Lightweight, mobile, can be carried to remote sites. Some manual models can even work without external power.

Durability

- DX68: Built for continuous heavy use, long service life with proper maintenance.

- Portable Units: Adequate durability but not designed for prolonged, heavy-duty crimping.

Cost and Investment

- DX68: Higher upfront cost but offers long-term ROI through efficiency and reduced downtime.

- Portable Units: Lower cost, budget-friendly, but may require more frequent replacement under heavy use.

Industry Fit

- DX68: Oil & gas rigs, refineries, large workshops, manufacturing plants.

- Portable Units: Construction sites, agricultural equipment repair, mobile service teams.

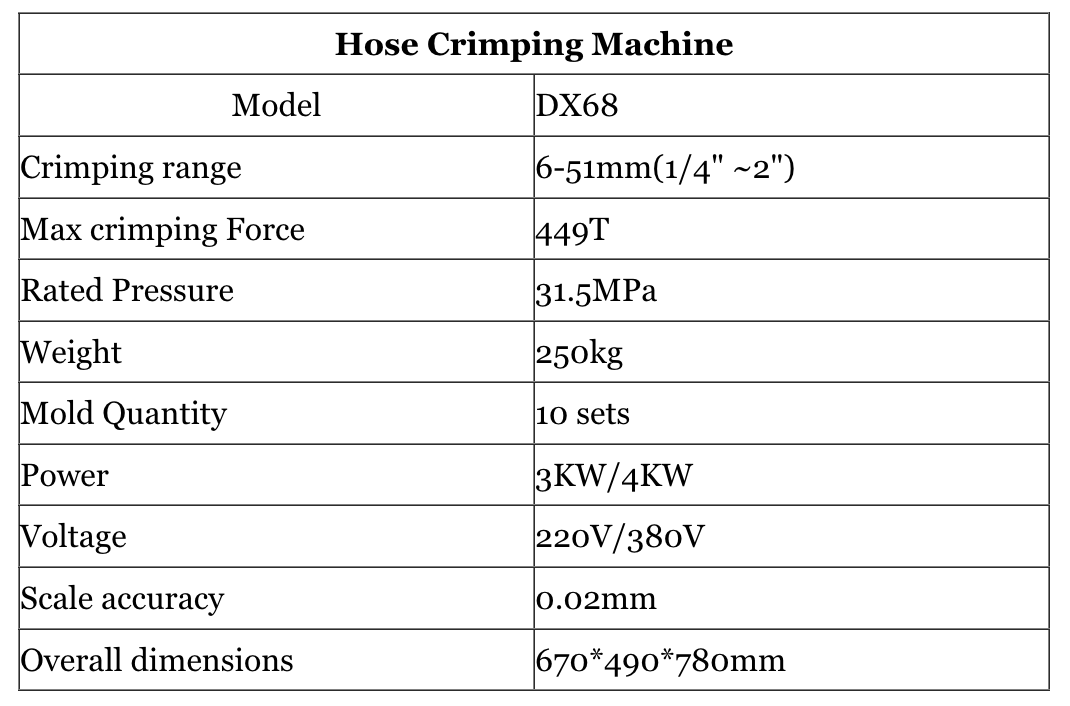

Specification of Kaida DX68 Hydraulic Hose Crimping Machine

Quick Comparison Table

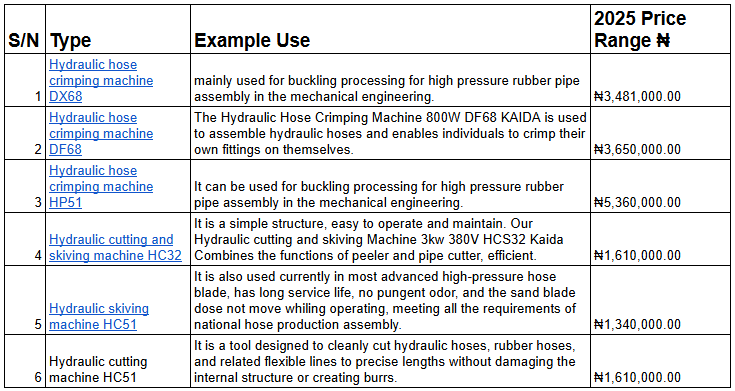

Price Guide in Nigeria (2025 Update)

Note: Prices vary by brand Kaida, die set inclusion, motor size, and exchange-rate/logistics. Use these as planning ranges.

Typical Machine Prices (equipment only)

Key Buying Considerations

Before purchasing a hydraulic hose crimping machine in Nigeria, here are the most important factors to weigh:

Type of Hoses You Crimp Most Often

- Consider the diameter and pressure rating of hoses in your daily operations. Large-diameter, high-pressure hoses require a heavy-duty unit like the DX68, while smaller hoses can be handled by portable units.

Expected Crimping Volume

- If your team crimps hoses daily in high volumes, a workshop-based machine is best for durability and efficiency. For occasional or emergency repairs, portable units are more cost-effective.

Workshop vs. On-Site Needs

- Ask yourself: Will most work happen in a fixed facility (favoring DX68) or in the field (favoring portable machines)? Mobility is critical for construction and agriculture, while precision is critical for oil & gas.

Availability of Spares and After-Sales Support in Nigeria

- Always confirm that dies, spare parts, and service are readily available locally. Trusted suppliers like Epoxy Oilserv, GZ Industrial Supplies, and Tikweld Welding Supplies provide warranty and technical support, which is vital for long-term ROI.

Frequently asked questions

1. Can portable crimping machines handle high-pressure hoses?

Portable units can handle light to medium-duty hoses, but for large-diameter, high-pressure applications, a DX68-class machine is recommended.

2. Which machine is best for oil & gas applications?

The DX68 or equivalent heavy-duty crimpers are best for oil & gas, offshore, and refinery environments where hoses must withstand extreme pressures and continuous duty cycles.

3. How long do crimping dies last?

With proper use and maintenance, crimping dies can last several years, though lifespan depends on usage frequency, hose materials, and care during operation.

4. Where can I buy genuine DX68 and portable hose crimpers in Nigeria?

For authenticity and warranty, purchase from authorized suppliers like Epoxy Oilserv, GZ Industrial Supplies, or Tikweld Welding Supplies. They offer both machines and spare parts with nationwide delivery.

Conclusion

When it comes to hydraulic hose crimping machines, the choice between a Kaida DX68 and portable units boils down to your unique needs.

The DX68 offers precision, durability, and industrial-grade performance, making it the top choice for oil & gas, refineries, and high-volume workshops.

Portable crimpers, on the other hand, provide mobility, affordability, and field flexibility, ideal for construction, agriculture, and mobile service teams.

There’s no one-size-fits-all solution. The best machine depends on your workload, budget, and industry demands. What matters most is investing in authentic equipment that guarantees efficiency, reliability, and safety.

Ready to make the right choice for your business? Visit GZ Industrial Supplies today to order genuine Kaida DX68 and portable hydraulic hose crimping machines. Benefit from expert advice, warranty assurance, and fast nationwide delivery to keep your operations running without interruptions.