The Ultimate Guide to Choosing the Right Hose Crimping Machine

The use of Hose crimping machine in the automotive, hydraulic engineering, industrial manufacturing, or any field that relies on fluid transport systems, ensures seamless connections and prevent costly leaks, between smooth production and unexpected downtime. Choosing the right hose crimping machine is a decision that can make or break the integrity of your operations. In various industrial applications precision and efficiency are paramount, the proper assembly of hoses and connectors is not a matter of chance.

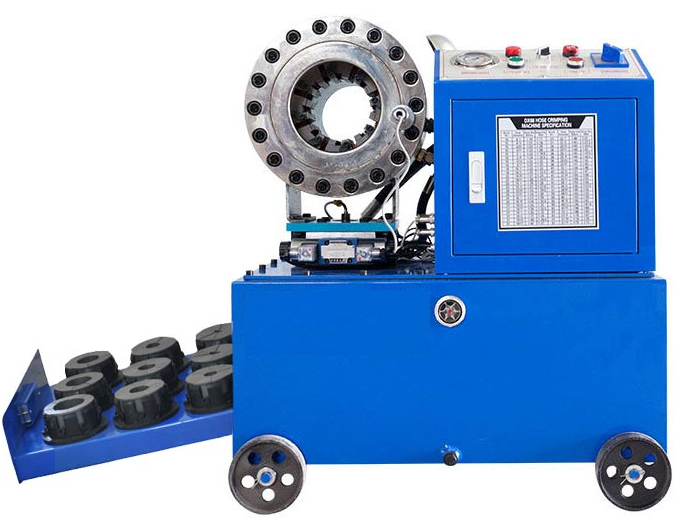

AVAILABLE... Hydraulic Hose Crimping Machine 220V DX68W KAIDA

Hose assembly forms the backbone of an array of industries spanning from automotive engineering to heavy machinery manufacturing. In the automotive sector, precise hose assembly is indispensable for the efficient functioning of brake and fuel lines. The aerospace industry relies on meticulously crimped hoses to withstand the demanding conditions of flight. In the realm of hydraulics, where power transmission is paramount, a perfectly crimped hose is the conduit through which immense forces flow.

Beyond these high-profile sectors, industries as diverse as construction, agriculture, and pharmaceuticals all rely on hose assemblies for seamless operations. Whether it's conveying vital fluids, gases, or chemicals, the integrity of these connections can mean the difference between a smoothly running operation and costly downtime.

Welcome to "The Ultimate Guide to Choosing the Right Hose Crimping Machine." If you find yourself faced with the daunting task of selecting the ideal hose crimping machine for your specific needs, you're in the right place. In the pages that follow, we will unravel the intricacies of hose crimping technology, guiding you through the maze of options, features, and considerations that define this critical piece of equipment.

By the time you reach the end of this comprehensive guide, you'll be armed with the knowledge and confidence to make an informed decision, ensuring that your hose assembly processes are not only efficient but also built on a solid foundation of quality and reliability. Whether you're a seasoned professional seeking to stay up-to-date with the latest industry trends or a novice exploring the world of hose crimping for the first time, this guide is designed to provide you with valuable insights and practical tips to help you choose the perfect hose crimping machine for your specific requirements. Let's embark on this journey together, demystifying the world of hose crimping machines, and empowering you to make the right choice with confidence.

Understanding Hose Crimping

Hose crimping is a method of joining hydraulic hoses and fittings by compressing them together using a crimping machine. The machine applies a specific amount of force to deform the fitting and hose, creating a tight and secure connection. Hose crimping plays a vital role in fluid transport systems, such as hydraulic, pneumatic, and industrial applications. The importance of secure connections cannot be overstated, especially in hydraulic or pneumatic systems. Crimped connections ensure a leak-free connection, eliminating the potential hazards associated with fluid leaks, such as environmental contamination and safety risks. Additionally, crimped connections provide enhanced strength and durability, allowing the fluid transport system to withstand high pressures and demanding operating conditions. On the other hand, poor crimping can have serious consequences for the fluid transport system and its users. Poor crimping can result in leaks, bursts, or blow-offs, which can cause damage to the equipment, loss of fluid, reduced performance, increased maintenance costs, and even injury or death. Therefore, it is essential to follow the proper crimping procedures and use the appropriate tools and equipment.

Types of Hose Crimping Machines

When it comes to hose crimping machines, there are various categories and options available, each tailored to specific applications and preferences. Understanding the different types of hose crimping machines is crucial to making an informed choice for your particular needs.

Hydraulic Hose Crimping Machines:

Hydraulic crimpers are commonly used for heavy-duty applications where high pressure and large-diameter hoses are involved. These machines employ hydraulic power to exert the force needed for crimping. They are favored for their precision, ability to handle a wide range of hose sizes and also deliver consistent and reliable crimps.

Pneumatic Hose Crimping Machines:

These machines operate using compressed air to generate crimping force. They are efficient, reliable, and easy to operate, and are often preferred in industries where electricity is not readily available or where pneumatic systems are already in use. Another advantage they have is being more lightweight and portable when compared to their hydraulic counterparts.

Manual vs. Automatic Crimping Machines:

A key consideration when choosing a hose crimping machine is the degree of automation required. Manual crimping machines rely on the operator's physical force to complete the crimp, offering control, portability and cost effectiveness, but exerting more labor. In contrast, automatic crimping machines, also known as power crimpers, are mechanized with advanced features such as programmable settings, digital controls, and integrated safety mechanisms. They can handle high volumes of crimping with less physical effort where speed, accuracy, and repeatability are crucial.

Custom vs. Standard Solutions:

Depending on your specific application and hose requirements, you may need a custom crimping solution. Custom crimping machines are designed to meet unique specifications and hose dimensions. Standard crimping machines are based on common specifications and standards, such as DIN, SAE, or ISO. They provide convenience and compatibility for general needs. By understanding these distinctions, you can make an informed choice when selecting a hose crimping machine that aligns with the nature of your projects and the level of automation you need.

Buy Online... Hydraulic Hose Crimping Machine 220V DX68 KAIDA

Factors to Consider When Choosing a Hose Crimping Machine

When selecting a hose crimping machine, there are several factors that you should consider to ensure that you choose the right machine for your needs and to ensure that your fluid transport systems are safe, efficient, and reliable These factors include:

Hose and fitting compatibility:

The first and foremost consideration is the compatibility of the machine with your hoses and fittings. Some machines may have different specifications and requirements for the hoses and fittings that they can handle. For example, some machines may only be able to crimp certain materials, such as rubber, metal, or plastic, while others may be able to crimp a variety of materials. Similarly, some machines may only be able to crimp certain shapes, such as straight, elbow, or flange, while others may be able to crimp any shape. Therefore, it is important to check the compatibility of the machine with the hoses and fittings that you intend to use with current projects but also for potential future needs.

Crimping capacity and range:

Determine the crimping capacity of the machine, which refers to the largest hose diameter it can accommodate. Different machines may have different limits on the minimum and maximum hose diameters that they can crimp. For example, some machines may only be able to crimp hoses up to 1 inch in diameter, while others may be able to crimp hoses up to 6 inches in diameter. Therefore, it is important to choose a machine that can accommodate the hose sizes that you need. Ensure that the machine's crimping force is suitable for your applications, as different tasks may require different levels of pressure.

Mobility and space constraints:

The mobility and space constraints of a machine refer to the ease of moving and storing the machine. Different machines may have different weights, sizes, and shapes, which affect their mobility and space requirements. For example, some machines may be portable and lightweight, while others may be fixed and heavy. Similarly, some machines may be compact and easy to store, while others may be bulky and require more space. Therefore, it is important to consider the mobility and space constraints of the machine in relation to your facility layout and workflow.

Safety features and regulations:

The safety features and regulations of a machine refer to the measures that are taken to ensure the safety of the operator and the environment when using the machine. Different machines may have different safety features and regulations that they comply with. Look for features such as safety guards and emergency stops to mitigate potential hazards during operation. Some machines may meet certain standards or certifications, such as CE, UL, or ISO, while others may not meet any standards or certifications at all. Therefore, it is important to choose a machine that has adequate safety features and regulations for your application. Additionally, training and certification in proper crimping procedures are essential to ensure the safety of the operator and the integrity of the hose connections.

Buy Online... Hydraulic Hose crimping machine YMC 102

Sizing and Compatibility of Hose Crimping Machine

When selecting a hose crimping machine, sizing and compatibility are crucial factors to consider. The importance of matching crimping machines to hose and fitting sizes cannot be overstated. Using the right size and compatible machine ensures a secure and leak-free connection, which is essential for the safety and efficiency of fluid transport systems. The key to proper crimping is the precise matching of machine and hose dimensions,and also selecting the right die sets.

Tips for selecting the right die sets

Die sets are an integral part of hose crimping machines, as they determine the size and shape of the crimp. It’s important to select die sets that are compatible with the hose and fitting sizes you intend to use. The right die set ensures that the crimp is uniform and leak-free. To make the right choice you should…

- Consider the range of hose sizes you will be working with and ensure that the die sets can accommodate those sizes.

- Look for die sets that are easy to change and adjust, as this will save time and improve efficiency during the crimping process.

- Check the manufacturer’s specifications and guidelines for recommended die sets for your specific machine model.

Understanding the implications of mismatched sizes

Mismatched sizes between the crimping machine, die sets, hoses, and fittings can lead to improper crimping, which can cause leaks, bursts, or blow-offs. Using a crimping machine or die set that is too large or too small for the hose and fitting can result in an insecure connection, reducing the reliability and safety of the fluid transport system. To avoid these issues, it’s essential to ensure that all components of the crimping process are properly matched in size and compatibility.

In summary, ensuring the correct sizing and compatibility between your hose crimping machine, hoses, and fittings is paramount. It guarantees the safety and reliability of your connections, minimizes the risk of leaks and inefficiencies, and ultimately supports the smooth operation of your fluid transport systems.

Buy Online... Hydraulic Hose Crimping Machine 800W DF68 KAIDA

Performance and Precision of Hose Crimping Machines

Crimping performance and precision are critical aspects of hose crimping machines, as they determine the quality and reliability of the crimped connections. Several factors come into play, including the force applied, accuracy in crimping, and the quality control measures in place.

A. The Role of Crimping Force and Accuracy

Crimping force is a critical factor that directly impacts the integrity of your hose connections. Applying the right amount of force is essential. Too little force may result in a loose connection, while excessive force can damage the hose or fitting. Modern hose crimping machines are equipped with hydraulic or pneumatic systems that precisely control crimping force, ensuring uniform and strong connections. Crimping accuracy is equally vital, as it dictates how well the hose and fitting are merged. A machine with adequate crimping force and accuracy can ensure a uniform and secure crimp that meets the specifications of the terminal manufacturer. Modern machines incorporate advanced technologies to provide consistent and precise crimps, guaranteeing reliability and safety.

B. Tolerance Levels and Quality Control

Hose crimping, particularly in industrial applications, demands strict adherence to tolerance levels. Tolerance is the permissible limit of variation to the precise measurements of the crimped connection. High-quality hose crimping machines often include built-in quality control features to verify that the crimped connection complies with industry standards. These features may include measurement sensors, visual inspection systems, and data logging. Some common methods of measuring and inspecting crimps include visual inspection, pull test, cross-section analysis, micrograph analysis, electrical test, and dimensional test. A machine with low tolerance levels and high quality control can ensure a consistent and reliable crimp that meets or exceeds the expectations.

Maintenance and Upkeep of Hose Crimping Machines

Machine maintenance and upkeep are essential for ensuring the optimal performance and longevity of your hose crimping machine. By following proper maintenance routines, troubleshooting common issues, and prolonging the machine’s lifespan, you can save time, money, and resources, as well as improve the quality and safety of your crimped connections.

Regular maintenance routines

These are the basic tasks that you should perform on a regular basis to keep your machine in good working order. Such as cleaning, lubricating, inspecting, testing, and calibrating the machine components.

- Cleaning involves removing any dirt, dust, grease, or debris from the machine surfaces, especially the die sets and the crimping area. This prevents contamination and corrosion of the machine parts.

- Lubricating involves applying oil or grease to the moving parts of the machine, such as the motor, pump, cylinder, valve, and die sets. This reduces friction and wear and tear of the machine parts.

- Inspecting involves checking the machine parts for any signs of damage, wear, or misalignment, such as cracks, dents, scratches, or loose connections. This helps identify any potential problems that may affect the crimping quality or cause failure.

- Testing involves verifying the functionality and accuracy of the machine components, such as the crimping force, pressure, speed, and diameter. This helps ensure the machine is operating within the specified parameters.

- Finally, when it comes to calibrating, you adjust the machine settings to match the desired crimping specifications, such as the crimping force, pressure, speed, and diameter. This helps ensure that the machine produces consistent and precise crimps that meet or exceed the expectations.

Buy Online... Hydraulic Hose crimping machine PM20

Troubleshooting common issues

When it comes to troubleshooting common issues, to diagnose and resolve any problems that may occur with your machine during operation. You should consider the following:

- Leaks may occur due to damaged or worn seals, hoses, fittings, or valves. They may cause fluid loss, pressure drop, or contamination of the machine parts. To fix leaks, simply replace or repair the faulty components.

- Noises usually occur due to loose or misaligned parts, such as bolts, nuts, screws, or die sets. To fix noises, you should tighten or replace the loose or misaligned parts and check for any other sources of noises.

- Vibrations can happen due to unbalanced or misaligned parts, such as the motor, pump, cylinder, valve, or die sets. They can cause instability or reduced accuracy of the machine. To fix vibrations, balance or align the unbalanced or misaligned parts and check for any other sources of vibrations.

- Errors may occur due to faulty or malfunctioning components, such as the sensor, controller, display, or switch. They may cause incorrect or inconsistent crimping results or prevent the machine from operating normally. To fix errors, you should troubleshoot or replace the faulty or malfunctioning components and check for any other sources of errors.

- Malfunctions could be due to power supply issues, such as low voltage, power outage, or short circuit. They may cause the machine to stop working or operate abnormally. To fix malfunctions, you should check and restore the power supply and check for any other sources of malfunctions.

Additionally, most manufacturers provide troubleshooting guides in their user manuals, which can be a valuable resource in solving issues.

Prolonging the machine’s lifespan

Extending the lifespan of your hose crimping machine not only saves you money but also ensures consistent performance. Proper maintenance significantly contributes to this goal. However, there are some measures that you should take to extend the service life and performance of your machine.

- Follow the manufacturer’s recommendations and guidelines for operating and maintaining the machine. This helps ensure that you use the machine correctly and safely.

- Use quality hoses and fittings that are compatible with your machine and application. This helps prevent damage or failure of the machine components due to incompatible materials or sizes.

- Avoid overloading or overheating the machine, by keeping it within its rated capacity and operating temperature. This helps prevent stress or damage of the machine components due to excessive force or heat.

Buy Online... Hydraulic Hose Crimping 4KVA /220-415V HP51 KAIDA

Cost and Budgeting

When choosing a hose crimping machine, it's crucial to consider various cost factors to ensure that your investment aligns with your budget and long-term financial objectives.

Cost Considerations:

Begin by thoroughly assessing the total cost of acquiring and operating a hose crimping machine. This includes the initial purchase price, any necessary accessories or additional tools, and ongoing operational costs. Consider whether there are hidden costs, like training for your staff or maintenance expenses.

Budget-Friendly Options:

Depending on your budget, you may explore different options. There are both entry-level and high-end hose crimping machines available. While advanced models may offer more features and precision, it's essential to weigh the benefits against your budget constraints. Consider what features are essential for your specific applications and whether budget-friendly options can fulfill those requirements.

Long-Term Cost-Effectiveness vs. Upfront Expenses:

One key consideration is the balance between upfront expenses and long-term cost-effectiveness. Cheaper machines may seem more appealing initially, but they may result in higher operational and maintenance costs over time. On the other hand, investing in a high-quality machine might require a more significant upfront payment, but its efficiency, precision, and durability could lead to substantial savings down the line.

Operational Efficiency:

Don't forget that the operational efficiency of your hose crimping machine plays a significant role in your overall budget. A more efficient and precise machine can lead to reduced material waste and better quality crimps, ultimately saving you money in the long run.

Training Costs:

Training your personnel on using the machine effectively and safely is another budget factor. It's essential to account for these costs to ensure that your team can operate the machine correctly and prevent accidents or costly mistakes.

Frequently Asked Questions

Q1 What is a hose crimping machine used for?

The crimping machine facilitates the process of crimping the fittings on the ends of the hoses, allowing the hose assembly to be connected to the appropriate flow system. Crimping machines are handheld, battery-operated, lightweight, and portable tools used to crimp or fasten metal fittings to stiff hose ends.

Q2 Which tool used for crimping hydraulic hose?

To join the ends of two cables, wires, or other similarly flexible materials, such hydraulic hoses, to a matching hose end, one uses a hydraulic crimper. By transferring force from the user to the tool via a hydraulic fluid system, this tool enables the user to make crimped connections.

Q3 What is a hydraulic crimping machine?

A hydraulic crimping hose machine is primarily used for connecting to the end of a variety of hose sizes and fabricating hose assemblies. The hose is connected by crimping one or both ends to ensure that the two portions are held together.

Related Article:

MECHANISM OF HYDRAULIC HOSE CRIMPING MACHINE

The Ultimate Guide to Choosing the Right Hose Crimping Machine

Buy Online... Hydraulic Hose crimping machine YMC 10Lc

Conclusion

Choosing the right hose crimping machine is a crucial decision that can have a significant impact on your fluid transport systems and your business success. A hose crimping machine is a device that crimps or compresses a metal fitting onto a hose, creating a secure and leak-free connection. There are different types of hose crimping machines available in the market, each with its own advantages and disadvantages. Some of the main factors that you should consider when choosing a hose crimping machine are:

- Hose and fitting compatibility: The machine should be compatible with the types of hoses and fittings that you intend to use, in terms of material, shape, and size.

- Crimping capacity and range: The machine should be able to accommodate the range of hose sizes that you need, from the minimum to the maximum diameter.

- Mobility and space constraints: The machine should be easy to move and store, depending on your facility layout and workflow.

- Safety features and regulations: The machine should have adequate safety features and comply with the relevant standards and certifications for your application.

- Performance and precision: The machine should deliver high-quality and consistent crimps that meet or exceed the specifications of the terminal manufacturer and the expectations of the customer.

- Maintenance and upkeep: The machine should be easy to maintain and repair, with low operating costs and long service life.

- Cost and budgeting: The machine should offer the best value for your money, considering the initial investment, the operating cost, and the return on investment.

By following these guidelines, you can make an informed decision that suits your specific needs. A hose crimping machine is not only a tool, but also an investment that can enhance your productivity, profitability, and reputation. Therefore, you should choose wisely and carefully, as it can make a difference between success and failure. We hope that this article has helped you understand the basics of hose crimping machines and how to choose the right one for your needs. For more information, or if you’re in the market for a hose crimping machine…Contact Us Today.

Recent Posts

-

How to Choose the Right Industrial Cleaning Service Provider

Key takeawayThoroughly Assess Your Needs and Providers: Understand your specific industrial cle …Jul 26, 2024 -

Floor Paint Maintenance: How to Keep Your Floors Looking Their Best

Maintaining your painted floors is essential for preserving their beauty and extending their lifespa …Jul 25, 2024 -

The Best Floor Paint for Different Types of Flooring

When it comes to revitalizing your home's flooring, choosing the right paint can make all the d …Jul 19, 2024