Nylon vs Polypropylene Rope:Which is Best for Your Job?

Introduction

Ropes are among the most versatile and essential tools across industries, from construction and marine operations to agriculture and everyday household tasks. Choosing the right rope material can significantly impact safety, durability, and cost-effectiveness. Two of the most widely used rope types are nylon and polypropylene, each offering unique advantages depending on the job at hand.

In this guide, we’ll break down the key differences between nylon and polypropylene ropes, highlight their strengths and weaknesses, and provide practical insights to help you select the best option for your specific needs.

Key Takeaway

-

Nylon excels in strength and elasticity, making it ideal for dynamic loads, shock absorption, and heavy-duty industrial use.

-

Polypropylene is lightweight, floats on water, and is more affordable, making it suitable for marine, fishing, and temporary applications.

-

Choosing the right rope depends on load requirements, environmental exposure, and budget, ensuring safety and performance in industrial tasks.

Understanding Rope Materials

Nylon Rope

Composition & Characteristics

Nylon ropes are made from synthetic polyamide fibers, giving them exceptional tensile strength and elasticity. They are known for being tough, durable, and resistant to abrasion.

Strength & Durability

Nylon is one of the strongest rope fibers available, with a high breaking strength that makes it ideal for heavy-duty applications like lifting, towing, and load securing. Its ability to stretch under load also helps absorb shock, reducing stress on equipment and improving safety.

Environmental Resistance

- Excellent resistance to abrasion and friction.

- Good tolerance to heat and UV rays, though long-term sunlight exposure can gradually weaken fibers.

- Moderate resistance to chemicals, but less effective against acids.

Typical Applications

Because of its superior strength and flexibility, nylon rope is commonly used in construction, marine mooring lines, climbing, towing, and rescue operations.

Polypropylene Rope

Composition & Characteristics

Polypropylene ropes are made from lightweight synthetic thermoplastic polymer fibers. This makes them lighter than nylon, and uniquely buoyant, meaning they float on water.

Strength & Durability

While not as strong as nylon, polypropylene offers decent strength for general use. It is best suited for lighter loads and short-term applications where cost and portability are more important than extreme durability.

Environmental Resistance

- Excellent resistance to water (it doesn’t absorb moisture and floats).

- Highly resistant to many chemicals, including acids, alkalis, and solvents.

- However, it has lower resistance to UV exposure, making it less durable for long-term outdoor use.

Typical Applications

Polypropylene ropes are widely used in water sports, agriculture, packaging, and temporary construction tasks. They are also common in safety lines around pools and as general-purpose household ropes due to their affordability.

Key Differences Between Nylon and Polypropylene Rope

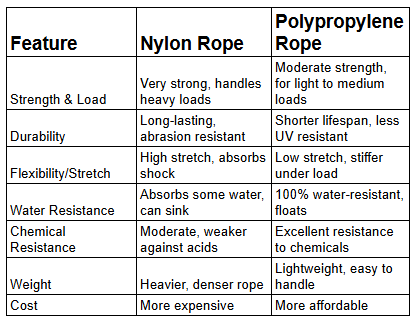

When comparing nylon and polypropylene, several performance factors stand out:

Applications of Nylon Rope

Because of its strength, flexibility, and shock absorption, nylon rope is often the go-to choice for heavy-duty and safety-critical applications.

Marine & Boating

- Ideal for anchor lines, mooring ropes, and dock lines.

- Handles constant tension from tides and waves due to its stretch properties.

- Resistant to abrasion when rubbed against piers, cleats, or rocks.

Construction & Industrial Use

- Common in lifting, towing, and rigging operations.

- Handles high loads without breaking easily.

- Preferred in building sites for hoisting materials and securing scaffolding.

Rescue & Safety Operations

- Nylon’s shock-absorbing capacity makes it perfect for climbing ropes, rescue lines, and harness systems.

- Provides extra safety in dynamic situations where sudden pulls are likely.

Automotive & Transport

- Used in tow ropes and straps.

- Strong enough for moving disabled vehicles and heavy loads.

Applications of Polypropylene Rope

Polypropylene ropes are valued for their lightweight nature, water resistance, and affordability. They shine in areas where portability and cost savings are more important than extreme strength.

Water Sports & Pool Safety

- Floats on water, making it perfect for swimming pool safety lines, watercraft towing, and water rescue.

- Widely used in fishing nets and boat lines for small-scale water operations.

Agriculture & Gardening

- Useful for tying, bundling, and hauling lightweight farm equipment or produce.

- Ideal for fencing, shading nets, and temporary crop supports.

Packaging & Light Duty Hauling

- Popular in warehouses and logistics for tying cartons and securing lightweight goods.

- Used as a general-purpose rope in households and shops due to its affordability.

Construction (Temporary Use)

- Handy for short-term binding or light lifting tasks.

- Often used when cost matters more than long-term strength, such as temporary scaffolding tie-downs.

Which Rope is Best for Your Job?

The decision between nylon and polypropylene rope depends on your specific use case:

Choose Nylon Rope if:

- You need strength, durability, and shock absorption.

- Applications involve heavy lifting, towing, or rescue work.

- Long-term outdoor use is required, where abrasion and load stress are frequent.

Choose Polypropylene Rope if:

- You need a lightweight, floating, and affordable rope.

- The job involves water environments, agriculture, or packaging.

- You require a temporary or budget-friendly solution.

Safety and Maintenance Tips

No matter which rope you choose, proper use and care are essential to ensure long-lasting performance and safety.

Storage

- Keep ropes in a cool, dry place away from direct sunlight.

- Avoid damp or chemical-prone environments that may degrade fibers.

Inspection

- Regularly check for fraying, cuts, or worn spots before use.

- Replace ropes that show significant wear to avoid accidents.

Proper Usage

- Always use the right rope for the right job (don’t overload a polypropylene rope in a heavy-duty lift).

- Follow load and safety ratings provided by the manufacturer.

Cleaning

- Wash ropes in clean water after exposure to salt or chemicals.

- Let them dry fully before storage to prevent mold or weakening.

Frequently Asked Questions

1. Which rope is stronger—nylon or polypropylene?

Nylon rope is significantly stronger and more durable than polypropylene, making it better for heavy-duty tasks.

2. Can polypropylene rope be used for towing?

Not recommended for heavy towing. It’s better suited for light hauling, packaging, or water-based activities.

3. Is nylon rope waterproof?

Nylon absorbs some water and sinks, but it remains durable when wet. For buoyant applications, polypropylene is better.

4. Which rope lasts longer outdoors?

Nylon rope generally lasts longer due to its abrasion and UV resistance, while polypropylene may degrade faster under sun exposure.

5. What is the most affordable rope option in Nigeria?

Polypropylene is usually cheaper, making it a cost-effective choice for light-duty or temporary tasks.

Conclusion

Selecting between nylon and polypropylene ropes depends on the job’s specific demands—strength, elasticity, water resistance, or budget. Nylon offers superior durability and shock absorption for heavy-duty use, while polypropylene provides lightweight versatility and cost-effectiveness for marine and general-purpose tasks.

For premium-quality ropes tailored to your industrial needs, visit GZ Industrial Supplies today and explore a wide range of durable nylon and polypropylene ropes designed for safety, reliability, and performance.