Surface Maintenance in Nigeria: Best Strategies to Extend Lifespan (2025 Guide)

Introduction

Imagine walking into a commercial facility where every surface gleams from the floors to the walls and exterior structures. Clean, well-maintained surfaces not only enhance the aesthetic appeal of a space but also reflect high standards of professionalism and care. Now imagine the opposite: scratched tiles, stained walls, rusted metals instantly, the environment feels neglected and possibly unsafe.

In Nigeria's growing industrial and commercial environments, surface integrity plays a vital role in operational success. Whether it’s heavy machinery, production floors, exterior walls, or decorative elements, each surface endures intense stress and exposure that can lead to costly damage if left unaddressed.

At the heart of surface protection is a robust maintenance strategy, a combination of inspection, cleaning, protection, and repair. Two core strategies that deliver the most value are regular inspections and protective coatings. These practices, when implemented effectively, delay wear and tear, prevent operational downtime, and reduce the need for expensive refurbishments.

In this guide, we explore the top techniques for maximizing the lifespan of surfaces in industrial, commercial, and residential settings across Nigeria

Buy online Epochem Polyurethane Floor Paint

Key Takeaways

- Regular Cleaning Prevents Damage: Consistently removing dirt, grime, and contaminants from surfaces helps prevent long-term damage and wear.

- Use the Right Products: Selecting appropriate cleaning and maintenance products based on the material of the surface ensures longevity and maintains its appearance.

- Protective Coatings Are Essential: Applying protective coatings, such as sealants or varnishes, can shield surfaces from environmental factors like UV rays, moisture, and abrasion.

- Prompt Repairs Extend Lifespan: Addressing minor damages, such as scratches or cracks, immediately can prevent further deterioration and costly repairs.

- Scheduled Maintenance Increases Durability: Establishing a regular maintenance schedule tailored to the specific needs of your surfaces helps maximize their lifespan and ensures they remain in top condition.

Why Surface Maintenance is Essential

Surface degradation is inevitable, especially in industrial environments. However, without proper upkeep, surfaces deteriorate faster, increasing operational costs and reducing safety. The first step in effective maintenance is understanding what causes surface degradation:

- Environmental Exposure: Surfaces exposed to Nigeria's intense sun, heavy rains, and humidity can suffer from UV damage, moisture seepage, and cracking.

- High Traffic Wear: Repeated use in areas like production floors or loading bays results in scratches, abrasions, and structural wear.

- Corrosion: Metal surfaces are especially prone to corrosion, particularly in coastal or humid regions.

- Chemical Deterioration: Facilities using harsh cleaning agents or manufacturing chemicals face accelerated degradation if surfaces are left unprotected.

Protecting your surfaces means protecting your investment. By implementing proactive maintenance, you not only preserve surface appearance but extend their structural integrity and performance.

Effective Maintenance Strategies

Regular Cleaning and Inspection

Routine cleaning is one of the simplest yet most impactful maintenance actions. It removes damaging debris and prevents the buildup of harmful substances. Use appropriate cleaning solutions tailored to the surface type — for example, degreasers for workshop floors and pH-neutral cleaners for tiled areas.

Pair cleaning with scheduled inspections. Create a maintenance checklist and inspect surfaces for early signs of damage such as:

- Cracks or surface erosion

- Bubbling or peeling paint

- Discoloration or damp spots

Detecting and fixing these signs early helps avoid large-scale repairs or replacements.

Application of Protective Coatings

Protective coatings form a crucial barrier between your surfaces and environmental stress. Options like Epochem Polyurethane Floor Paint or Epocoat Alkyd Gloss are designed to resist chemicals, abrasion, and UV rays.

For industrial flooring, consider visiting our article on where to buy epoxy flooring materials in Nigeria to source high-quality coatings for long-term protection.

These coatings reduce the frequency of maintenance and give surfaces a longer functional lifespan while also improving their aesthetic appeal.

Why Surface Maintenance Is Essential

Surfaces in industrial and commercial environments are constantly exposed to harsh conditions—from foot traffic and heavy machinery to fluctuating weather and chemical contact. Without a structured maintenance plan, these surfaces degrade quickly, leading to high replacement costs, operational downtime, and even safety hazards.

To proactively protect your infrastructure, it’s important to understand the major causes of surface wear:

- Environmental Exposure: UV rays, moisture, and temperature extremes break down coatings and weaken surfaces.

- Mechanical Stress: Constant use in high-traffic areas results in abrasion, dents, and scratches.

- Chemical Contact: Harsh cleaning agents or industrial chemicals corrode materials over time.

- Corrosion: Particularly in metal installations, corrosion is a silent threat—especially in humid or salty environments.

By addressing these risks early, businesses can preserve surface integrity, uphold safety standards, and significantly reduce their long-term maintenance budget.

Effective Maintenance Strategies

Regular Cleaning and Inspection

Routine cleaning is the first line of defense. Dust, grime, and residue from operations can act like sandpaper, slowly grinding down surface quality. However, the wrong cleaner can do more harm than good. It’s crucial to:

- Match cleaners to surface types (e.g., pH-neutral cleaners for stone, degreasers for machinery)

- Use non-abrasive tools to avoid scratching delicate finishes

- Inspect surfaces after cleaning for early signs of wear, such as peeling, bubbling, or discoloration

For example, Epochem degreasers are ideal for heavy industrial surfaces exposed to oil, grease, and chemicals.

Application of Protective Coatings

Protective coatings form a barrier against moisture, abrasion, and UV degradation. These include:

- Sealants and varnishes for decorative or wooden surfaces

- Epoxy and polyurethane floor coatings for warehouses, factories, and showrooms

- Specialty paints for metal, such as rust-preventive coatings or enamel finishes

A top recommendation is Epochem Polyurethane Floor Paint—engineered to resist chemicals, water, and physical impact. Reapplying coatings every 1–2 years (or as wear becomes visible) helps preserve surface integrity and prevents costly restoration.

Routine Maintenance and Timely Repairs

Surfaces don't fail overnight, damage builds up gradually. That’s why routine maintenance is not optional but essential. It includes:

- Fixing scratches and chips as soon as they appear to prevent further spread

- Filling cracks and joints in concrete or epoxy floors before moisture infiltrates

- Reapplying protective finishes in high-traffic zones on a scheduled basis

Early intervention is significantly cheaper than full replacement. For instance, using Epocoat 304/305 Floor Paint, you can restore worn epoxy floors quickly without needing to strip and recoat an entire surface.

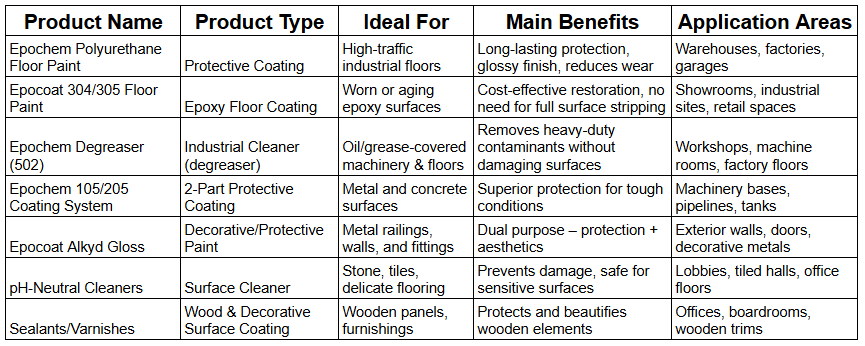

Comparison Table: Top Surface Cleaning and Protective Products in Nigeria

DIY Guide: Steps for Effective Maintenance

If you're managing surface upkeep yourself or training a facilities team, here’s a step-by-step maintenance framework:

Inspect:

- Scan for physical damage: cracks, chips, peeling paint

- Use a checklist to cover walls, floors, metal surfaces, and coated areas

- Pay extra attention after high-use periods or weather changes

Clean:

- Choose surface-appropriate cleaners (e.g., degreasers like Epochem 502)

- Clean gently yet thoroughly to avoid abrasive damage

- Rinse and dry properly to avoid watermarks or chemical buildup

Apply:

- Mix coating systems like Epochem 105 and 205 according to manufacturer specs

- Apply in thin, even layers using rollers or sprayers

- Mask adjacent areas and maintain a clean environment to reduce dust settling

Monitor:

- Keep a maintenance log with inspection dates, products used, and repair actions

- Record coating expiration dates and plan reapplication schedules

Educate:

- Train your team with updated best practices

- Attend workshops or speak with technical experts from suppliers like GZ Industrial Supplies

Engaging Professional Surface Maintenance Services

While DIY efforts help with regular upkeep, certain tasks require professional expertise—especially in industrial environments. Trained technicians bring:

- Specialized tools like abrasive blasters and electrostatic sprayers

- Expert application techniques that maximize coating adhesion and longevity

- Access to industrial-grade products like high-performance epoxy, alkyd, and polyurethane systems

They also ensure compliance with safety standards and material specifications, minimizing liability and project delays. For example, a certified team applying Epochem Polyurethane Floor Paint or Epocoat Alkyd Gloss ensures that the correct curing times, thicknesses, and environmental conditions are met.

Frequently Asked Questions

1. How often should I clean my surfaces to ensure they last longer?

High-traffic industrial floors may require daily cleaning, while less-used surfaces can follow a weekly or monthly schedule. Always adjust frequency based on use and exposure.

2. What type of cleaning products should I use to avoid damaging my surfaces?

Match the product to the surface type—non-abrasive cleaners for wood, pH-neutral for stone, and industrial degreasers for machinery. Avoid corrosive agents unless specifically required.

3. Why are protective coatings important for surface maintenance?

They act as a barrier, preventing water, chemicals, UV rays, and physical abrasion from degrading the substrate.

4. How can I tell when a surface needs to be resealed or recoated?

Look for signs like fading, chalking, stains, or water absorption. Loss of gloss and visible wear lines are also strong indicators.

Related Articles

Types of Surfaces: Common Maintenance Challenges and Solutions

Understanding the Importance of Regular Surface Maintenance for Property Owners

The Complete Guide to Surface Maintenance Solutions: Tips, Techniques, and Best Practices

Conclusion

Preserving your surfaces is not just about aesthetics—it's a smart financial decision. With proactive care, the right tools, and expert-grade coatings, your facilities can remain functional, safe, and professional-looking for years.

Explore our wide range of industrial coatings like Epochem Polyurethane Floor Paint, Epocoat 304/305, and more. Partner with GZ Industrial Supplies for expert guidance, free consultations, and fast delivery anywhere in Nigeria.