Where to Buy Epoxy Flooring Materials in Nigeria (Updated 2025 Guide)

Introduction

Epoxy flooring has become a go-to solution for many industries in Nigeria due to its unmatched strength, durability, and aesthetic appeal. Whether you're outfitting a commercial warehouse, a high-traffic showroom, or a residential garage, epoxy coatings offer a resilient and long-lasting surface that’s both functional and visually appealing.

This guide provides a comprehensive overview of epoxy flooring, why it's superior to other materials, and most importantly where to buy authentic, high-quality epoxy flooring materials in Nigeria from trusted suppliers like GZ Industrial Supplies.

Read more... Epoxy Flooring Professionals and Materials Near Me: A Guide to Finding the Right Contractor and Supplier

Key Takeaway

- Epoxy flooring is a durable, chemical-resistant solution ideal for residential, commercial, and industrial surfaces across Nigeria.

- The demand for high-quality epoxy materials is rising due to their long-lasting performance, ease of maintenance, and aesthetic appeal.

- When buying epoxy materials, prioritize trusted suppliers that offer verified products, technical support, and after-sales service.

What Is Epoxy Flooring?

Epoxy flooring is a durable coating system made by combining a Part A Resin (Epochem 105) and a Part B Hardener (Epochem 205). This chemical reaction forms a tough copolymer layer, perfect for surfaces requiring high resistance to chemicals, pressure, and wear. Thanks to its strong adhesive properties, epoxy flooring is used extensively in industrial and commercial settings, including:

- Manufacturing plants

- Oil & gas facilities

- Automotive garages

- Retail stores and showrooms

- Residential homes

Compared to vinyl or tile, epoxy offers superior strength, chemical resistance, and a seamless finish that makes cleaning and maintenance easy.

Why Choose Epoxy Flooring in Nigeria?

Durability:

Epoxy coatings can withstand heavy foot traffic, forklifts, and abrasive materials without cracking or losing integrity. Products like Epochem 105 Epoxy Resin offer superior strength for industrial-grade applications.

Versatile Applications:

From hospitals and airports to warehouses and food production facilities, epoxy coatings are versatile. Their high adaptability to various substrates makes them ideal for concrete floors in Nigeria’s diverse industries.

Easy Maintenance:

Epoxy-coated floors are seamless and impervious to dirt, grease, and chemicals. Simple mopping or pressure washing is often enough to keep the surface clean, reducing downtime and maintenance costs.

Cost Efficiency:

Despite their high performance, epoxy floors offer excellent value over time. Their longevity and minimal maintenance requirements often make them more economical than traditional flooring options.

Read more...Guide to Buying Industrial Floor Paint in Nigeria

Types of Epoxy Flooring Materials Available in Nigeria

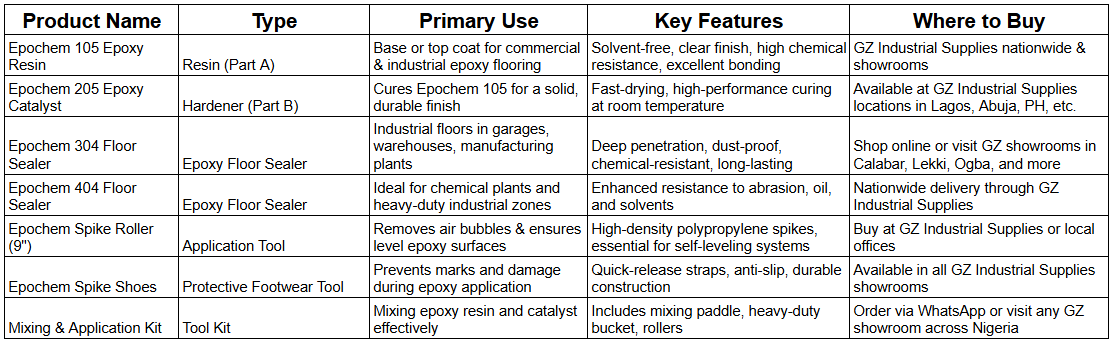

At GZ Industrial Supplies, we stock a comprehensive range of epoxy flooring products tailored to different project sizes and industries:

Epochem 105 Epoxy Resin

A clear, solvent-free resin ideal for decorative and protective coatings. Used as a base coat or top coat with outstanding bonding and chemical resistance.

Epochem 205 Epoxy Catalyst

This fast-drying hardener accelerates the curing of Epochem 105, delivering high-performance finishes at room temperature.

EPOCHEM 304/404 Floor Sealers

Designed for high-traffic industrial floors, these sealers penetrate deep into concrete to form a dust-free, chemical-resistant barrier—ideal for garages, warehouses, and factories.

Epoxy Flooring in Nigeria: Ultimate Comparison Table (2025 Guide)

How to Apply Epoxy Flooring the Right Way

Getting the most out of your epoxy flooring system starts with proper surface preparation and correct application techniques. Here’s what a typical process looks like for industrial and commercial spaces in Nigeria:

Step 1: Surface Preparation

- Clean and degrease the surface thoroughly to remove any oils, dust, or contaminants.

- Grind or shot-blast the concrete surface to open the pores and allow for better adhesion.

- Repair any cracks or joints with a suitable epoxy repair mortar.

Step 2: Primer Application

Apply a penetrating epoxy primer like Epochem 105 to create a strong base layer. This improves bonding and ensures even application of subsequent coats.

Step 3: Mixing the Epoxy Resin and Hardener

The key to a successful application lies in the correct mixing ratio:

- 2 parts Epochem 105 Resin

- 1 part Epochem 205 Catalyst

Mix thoroughly using a low-speed drill and mixing paddle for about 2–3 minutes. Improper mixing can lead to curing issues or surface defects.

Step 4: Applying the Body Coat

Pour the mixed epoxy onto the surface and spread it evenly with a roller or squeegee. For decorative finishes, graded aggregates or metallic pigments can be added at this stage.

Step 5: Spiked Rolling

Use the Epochem Spike Roller (9 inch) to:

- Eliminate air bubbles

- Help the resin level itself out

- Prevent uneven thickness and distortions

This tool is essential for industrial-grade epoxy installations, especially self-leveling floor systems.

Step 6: Curing and Final Finish

Allow the flooring to cure undisturbed for 24–48 hours. For higher chemical resistance and durability, post-curing with heat may be applied depending on your setting.

Read more...LONG DOES EPOXY FLOOR LAST

Essential Tools for Epoxy Flooring Professionals

At GZ Industrial Supplies, we not only supply materials but also stock professional-grade epoxy tools that help deliver perfect finishes every time:

Epochem Spike Shoes

- Prevent scuffs and marks during application

- Designed with ¾" Polypropylene spikes and quick-release buckles for ease and safety

Epochem Spike Rollers

- Available in various spike lengths for different thicknesses

- Ideal for use with self-leveling epoxy and polyurethane systems

Mixing and Application Kits

- Heavy-duty buckets, mixing paddles, and rollers designed to handle industrial-grade epoxy systems

Related Reading:

- To strengthen your epoxy project knowledge and improve your search engine visibility, also read:

- Benefits of Selecting a Metallic Epoxy Floor Coating

- Epoxy Floor Coating for Industrial Floor

Read more...HOW TO EXTEND THE LIFE OF YOUR EPOXY FLOOR

Where to Buy Epoxy Flooring Materials in Nigeria

If you're wondering where to buy epoxy flooring materials in Nigeria, look no further than GZ Industrial Supplies, Nigeria’s most trusted supplier of Epochem epoxy products, including Epochem 105 Resin, Epochem 205 Catalyst, Epochem 304/404 Floor Sealers, and essential tools like spike rollers and spike shoes.

Our Major Locations Include:

- Lagos (Ikeja, Lekki, Apapa, Ogba)

- Port Harcourt

- Calabar

- Abuja

We provide nationwide delivery, expert consultation, and customized flooring solutions tailored to your environment. For assistance or bulk orders, call or WhatsApp 08053390129

You can buy Epoxy Flooring Materials in our offices across Nigeria.

GZ Industrial Supplies Ikeja.

18 Adeshina street, Behind Holy Trinity Hospital Ikeja, Off Obafemi Awolowo Way Ikeja. Lagos State Nigeria. Tel. +234 8181069339, +234 9055793557 +234 9055793558, WhatsApp: +234 8181069339,

GZ Industrial Supplies Port Harcourt Showroom.

238 Aba Road First Artillery by Fidelity bank, Port Harcourt. Rivers State Nigeria. Tel. +234 8181069339, +234 9055793557 , +234 9055793558, WhatsApp: +234 9055793558, +234 8181069339

GZ Industrial Supplies Calabar Showroom.

30/32 Ndidem Usang-Iso, Marian Road, Calabar, Cross Rivers State Nigeria. Contact Tel. +234 8181069339, +234 9055793557, WhatsApp: +234 9055793557 +234 8181069339.

GZ Industrial Supplies Sango Ota Showroom.

Km 42 Lagos-Abeokuta Expressway, opposite Coronation Power and Gas Limited, Ado-Odo/Ota, Sango Ota.

GZ Industrial Supplies Ogba Showroom.

77/79 Yaya Abatan Road, Maternity Bus Stop. Ogba , Lagos NG, Ifako Agege, Ogba. Contact Tel.+234 8181069339, +234 9055793557, WhatsApp: +234 9055793557 +234 8181069339

GZ Industrial Supplies Abuja Showroom.

Shop 016, Zitel Plaza, Plot 227 P.O.W. Mafemi Crescent Utako, Abuja. Tel. +234 8053390161,+234 9121740191

GZ Industrial Supplies Lekki.

Suit 10 Sebuf plaza Lekki Epe Expressway Lekki Lagos. Tel. +234 8181069339, +234 8053390169 +234 9055793557

GZ Industrial Supplies Apapa.

Tel. +234 8181069339, +234 9055793557, +234 9055793558

Benefits of Epoxy Flooring: Why It’s the Top Choice

Whether in a factory, commercial kitchen, aircraft hangar, or residential garage, epoxy flooring stands out for its:

- Durability: Withstands forklifts, heavy tools, and vehicular traffic.

- Aesthetic Appeal: Available in matte, satin, or glossy finishes with metallic and flake options.

- Safety: Non-slip textures and chemical resistance make it ideal for industrial and food-grade environments.

- Low Maintenance: No waxing, buffing, or special care—just sweep and mop.

Frequently Asked Questions

1. How long does it take to install epoxy flooring?

Installation takes about 2–3 days, depending on the size and environmental conditions. Full curing can take up to 48 hours.

2. Can epoxy flooring be applied over tiles?

Yes, with proper grinding and levelling. Using a self-levelling compound is often recommended for best results.

3. Is epoxy flooring safe?

Yes, when applied with the correct PPE and ventilation. Epochem products have low VOCs and are safe for industrial and food environments.

4. What are the main tools needed?

Spike rollers, spiked shoes, mixing paddles, and precision application tools.

Related Articles

Epoxy Flooring materials and accessories shop

Where to Find Epoxy Flooring Supplies in Nigeria

Conclusion

Finding reliable, high-quality epoxy flooring materials in Nigeria doesn't have to be a challenge. Whether you're working on a commercial project, industrial facility, or residential upgrade, choosing the right supplier ensures your flooring investment is durable, attractive, and long-lasting.

For top-tier epoxy resins, hardeners, primers, and application tools, look no further than GZ Industrial Supplies. With nationwide delivery, expert product recommendations, and a reputation for supplying trusted brands like Epochem, they remain one of Nigeria’s leading sources for flooring materials in 2025.