TYPES OF GAS DETECTORS

Gases are one of the fundamental states of matter and the air around us is a mixture of pure gases existing naturally in a combined state. Hence there is need to detect each particular gas.

A Gas Detector is a gadget that detects the presence or existence of gases in an isolated location. This equipment is used to carefully search for gas leak or other emissions and can interface with a facility’s control system so a process can be automatically shut down.

GAS DETECTORS AS SAFETY EQUIPMENT

Gas Detection is necessary and is incorporated as part of the safety system of most Oil and Gas facilities as well as other industrial facilities because its integration can be used to detect combustible, flammable and toxic gases. Also, gas detection helps to monitor oxygen consumption in underground terrains (such as gold mines and coal mines), reasons being that reduced oxygen levels can cause dizziness in workers and potential passing out. If levels are too low it can cause serious brain damage or death. Gas detection may be employed in firefighting. In addition, a gas detector can sound warning or evacuation alarm to operators in the area where the leak is occurring, giving them time to leave the premises. This instrument is of immeasurable importance because there are many gases that can be harmful to organic life, such as plants, humans and animals.

Types of Gas Detectors

Gas detectors can be classified into two major form factors depending on their operation mechanism: Fixed and Portable Gas Detectors.

Portable Detection Systems: This is often employed to assist workers undertaking tasks such as maintenance, where employees might disturb or release gas that should not be freely roaming in that area. Portable detectors are also a useful way of sampling gases, where workers need to measure the quality of the atmosphere around personnel and are either hand-held or worn on clothing or on a belt/harness. These gas detectors are usually designed to run on battery. They transmit visible and audible signals through flash lamps and alarms when harmful gas vapor reaches dangerous levels.

Fixed Detection Systems: This as the name goes is mainly fixed at a position within the work area. Their placement position within the building or process plant is dependent on the gas density (whether the gas is heavier or lighter than air). Fixed type detectors are generally mounted near the process area of a plant or control-room, or an area to be protected and a cable connected to a monitoring system that can be activated during emergency, they may be used for detection of one or more gas types.

Types of Gas Detectors

There are types of gas detectors which are employed for peculiar industrial operations which include:

1. Electrochemical gas Detectors

Electrochemical sensors are used for detecting oxygen and toxic gases. More specifically, they measure the concentration of a specific gas within an external circuit. This is done by method of oxidation or reduction reactions.

These reactions generate the positive or negative current flow through said external circuit. An electrochemical sensor is made up of a "working" electrode, a "counter" electrode, and usually a "reference" electrode. All of these components sit inside of a sensor housing along with a liquid electrolyte.

2. Photo-ionization detectors

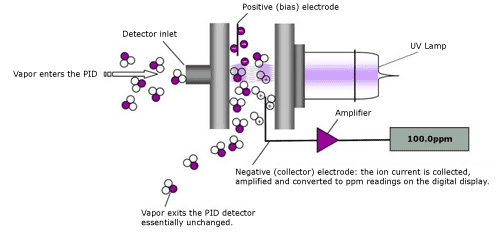

Photoionization detectors (PIDs) use a high-photon-energy UV lamp to ionize chemicals in the sampled gas. If the compound has an ionization energy below that of the lamp photons, an electron will be ejected, and the resulting current is proportional to the concentration of the compound. Common lamp photon energies include 10.0 eV, 10.6 eV and 11.7 eV; the standard 10.6 eV lamp lasts for years, while the 11.7 eV lamp typically last only a few months and is used only when no other option is available.

A broad range of compounds can be detected at levels ranging from a few ppb to several thousand ppm. Detectable compound classes in order of decreasing sensitivity include: aromatics and alkyl iodides; olefins, sulfur compounds, amines, ketones, ethers, alkyl bromides and silicate esters; organic esters, alcohols, aldehydes and alkanes; H2S, NH3, PH3 and organic acids. The PID is comprised of an ultraviolet lamp that emits photons that are absorbed by the compound in an ionization chamber. Ions (atoms or molecules that have gained or lost electrons and thus have a net positive or negative charge) produced during this process are collected by electrodes. The current generated provides a measure of the analyte concentration. Because only a small fraction of the analyte molecules are actually ionized, this method is considered nondestructive, allowing it to be used in conjunction with another detector to confirm analytical results. In addition, PIDs are available in portable hand-held models and in a number of lamp configurations. Results are almost immediate.

Infrared points Gas Detectors

Infrared Point gas detector

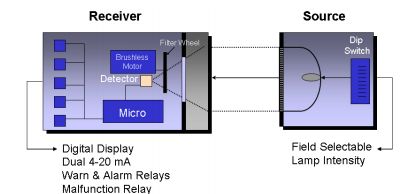

The Infrared (IR) method of measuring gas concentration is based on the absorption of IR radiation at certain wavelengths as the radiation passes through a volume of the gas. IR hydrocarbon gas detectors can be classified into two types known as point detectors and open path detectors. For point detectors, the absorption path length is fixed, and is determined by the instrument design to be a few inches. For the open path IR detectors, the absorption path length can be as long as 130 meters as opposed to the few inches of the point detector. Instruments based on IR technology use two wavelengths, one at the gas absorbing wavelength and the other at a wavelength not absorbed by the gas; neither wavelength is absorbed by the other atmospheric constituents such as water vapor, nitrogen, oxygen, or carbon dioxide.

IR gas sensing technology provides for fail-to-safe operation in contrast to electro-catalytic sensors since optical sensing is an active technology, which continuously monitors for sensor faults and communicates them to the user. This is achieved chiefly through the use of the second or reference wavelength. IR detectors are also immune to poisoning, resistant to corrosion, can operate in a deficit or surplus of oxygen, and do not suffer from reduction in sensor life on repeated exposure to gas. With the sophisticated optical and electronic designs currently being used, the detectors are factory calibrated and virtually maintenance free.

Other Gas-detecting equipment includes: Infrared imaging, Semi-conductor sensors, Ultra-sonic Gas leak detectors, Catalytic bead (pellistor) , Holographic gas sensors, etc. it is worthy of note that a Multi-Gas detector can be employed to replace some of the earlier mentioned detectors, because it was designed for events where a variety of gases need monitoring at the same time the detectors are preset to meet users’ individual requirements. They are commonly used for the following gases, hydrogen sulphide (H2S), Carbon monoxide (CO2), Oxygen (O2) and combustibles (%LEL). All gas detectors require regular calibration to ensure accuracy of the gas readings. It will interest you to know that you need not travel too far to make procurement for this equipment. We got you covered at GZ Industrial supplies world.

Frequently Asked Questions

Q1 What are the two types of gas detectors?

These many gas detector kinds can be broadly divided into two groups: fixed and portable. The environment of personnel is monitored using portable gas detectors, which are usually worn on safety equipment or are handheld devices.

Q2 What is a gas detector?

A gas detector, which is frequently a component of a safety system, is a device that detects the presence of gasses in an area. Operators in the vicinity of the leak can be given the opportunity to evacuate by having a gas detector alert them.

Q3 How do gas detectors work?

Toxic gases like carbon monoxide are measured by electrochemical gas detectors, which are incredibly sensitive. To raise the alert, they use electrodes that sense airborne electrodes to deliver an electric current.

Related Articles

Angle Grinder Safety Tips: Protecting Yourself and Your Workpiece

Safety Equipment in Nigeria 2023 Reviews

Top 10 Marine Supplies Every Boat Owner in Nigeria Needs

Recent Posts

-

The Best Transformer prices in Nigeria

A transformer facilitates the delivery of electrical energy at minimum power loss. The best and affo …Apr 18, 2024 -

Eco-Friendly Industrial Chemicals: The Future of Sustainability in Manufacturing

In the face of escalating environmental concerns, sustainability in the use of industrial chemicals …Apr 17, 2024 -

Innovative Features of Dongcheng Percussion Hammers

Power tools like percussion hammers are used in the construction and demolition industries for break …Apr 17, 2024