Epoxy Floor Coating for Hospitals: Benefits, Applications, and Installation Insights

Introduction

Hospitals are environments where safety, hygiene, and durability aren't just desired, they are absolutely essential. From operating rooms to waiting lounges, every square meter of hospital flooring is subjected to rigorous use, daily sanitization, and potential contamination from a wide variety of fluids and chemicals.

In such demanding spaces, traditional flooring materials often fail to meet the strict performance standards required. That’s where epoxy floor coatings shine. These coatings offer a seamless, non-porous, and highly durable surface that supports infection control, withstands chemical spills, and endures heavy foot and equipment traffic without compromising on safety or aesthetics.

As more healthcare facilities across Nigeria and beyond seek high-performance flooring solutions, epoxy has become the go-to material for both new hospital construction and renovation projects.

Key Takeaway

-

Hygienic and Easy to Clean: Epoxy floor coatings create a seamless, non-porous surface that resists bacteria, mold, and chemical stains—critical for infection control in healthcare environments.

-

Chemical and Impact Resistance: These coatings withstand exposure to harsh disinfectants, cleaning agents, and dropped medical tools without degrading or cracking.

-

Slip-Resistant and Safe: Epoxy floors can be formulated with anti-slip additives to minimize fall risks in high-traffic hospital areas, improving overall patient and staff safety.

-

Durability in High-Traffic Areas: Ideal for corridors, operating rooms, and laboratories, epoxy coatings handle constant foot traffic, rolling equipment, and stretcher movement without showing wear.

What Is Epoxy Floor Coating?

Epoxy floor coating is a thermosetting resin system that forms when epoxide resin is combined with a polyamine hardener. When applied to prepared concrete or other surfaces, it cures into a rigid plastic-like layer that bonds tightly with the substrate.

In medical environments, epoxy coatings are customized with additives such as:

- Antimicrobial agents to inhibit the growth of bacteria and mold

- Anti-static compounds for operating rooms and electronic diagnostics areas

- Slip-resistant textures to enhance safety even when wet

Unlike floor paints, true epoxy coatings are resistant to abrasion, impact, and a wide range of chemicals, making them ideal for areas where hygiene, durability, and safety must work together seamlessly.

Why Hospitals Need Specialized Floor Coatings

Hospitals are exposed to a combination of aggressive cleaning agents, bodily fluids, heavy equipment, and constant movement of patients and staff. This places unique demands on flooring that many conventional materials cannot meet.

Key reasons epoxy floor coatings are essential in hospitals include:

- Infection Control: Seamless surfaces leave no crevices for bacteria to hide or multiply

- Chemical Resistance: Epoxy resists damage from blood, disinfectants, and acidic cleaners

- Load Bearing: Withstands hospital beds, gurneys, wheelchairs, and diagnostic machines

- Safety Compliance: Options for anti-slip textures and low-VOC (Volatile Organic Compound) formulations

- Quick Turnaround: Fast-curing options minimize downtime during installations

In healthcare settings, floors are the front line of infection prevention. The ability to clean and disinfect thoroughly and frequently without damaging the floor is crucial.

Key Benefits of Epoxy Floor Coating in Hospitals

Here’s why epoxy stands out as the ideal hospital flooring system:

Seamless and Easy to Clean

No grout lines or seams mean no dirt traps. Epoxy creates a monolithic surface that can be easily sanitized daily without deterioration.

Antimicrobial Protection

Additives can inhibit the growth of bacteria, mold, and viruses—making epoxy safer for use in ICUs, surgical suites, and laboratories.

Durable and Long-Lasting

With proper installation and maintenance, epoxy can last 10+ years, even under extreme foot traffic and constant cleaning.

Chemical Resistance

Stands up to disinfectants, solvents, bodily fluids, and medications without staining or corroding.

Color Coding and Zoning

Different colors and textures can be used to delineate safe zones, restricted areas, and workflow directions.

Where Epoxy Floor Coatings Are Used in Hospitals

Epoxy coatings are not a one-size-fits-all solution they are engineered for specific use cases across hospital departments. Here are the top areas where epoxy flooring delivers exceptional performance:

Operating Rooms (ORs)

Cleanliness and contamination control are paramount. Epoxy’s non-porous surface reduces microbial buildup and withstands sterilizing agents. Anti-static properties are also crucial in sensitive OR environments.

Intensive Care Units (ICUs)

Constant monitoring and cleaning are required. Epoxy supports frequent sanitation, resists scuffing from beds and equipment, and offers antimicrobial protection.

Sterilization & Sanitation Areas

Infection control zones benefit from seamless flooring that doesn't harbor bacteria. Epoxy’s resistance to heat, moisture, and chemicals ensures durability even under extreme cleaning regimens.

Laboratories & Diagnostics Rooms

Spills from chemicals or biological materials demand a floor that resists chemical corrosion and is easy to clean. Epoxy meets these demands while providing a bright, professional finish.

Reception and Waiting Areas

Aesthetic appeal meets functionality. Epoxy floors can be customized with decorative flakes or quartz to resemble tile or granite, while maintaining industrial-grade durability.

Corridors and Hallways

These high-traffic zones benefit from epoxy’s abrasion resistance, keeping floors looking clean and professional even under constant foot and equipment movement.

Kitchens & Food Service Areas

Food safety is critical. Epoxy coatings are available in food-grade formulas, offering anti-slip properties, resistance to food acids, and compliance with sanitation codes.

Choosing the Right Epoxy System for Hospital Floors

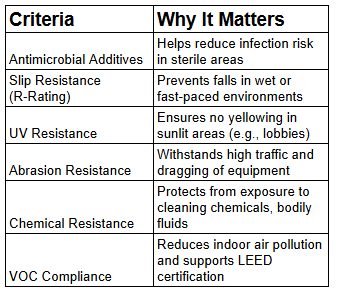

When selecting an epoxy floor coating for a hospital, facility managers must consider several factors beyond just durability. Here’s a guide to help with product selection:

Performance Criteria to Consider:

Recommended System Layers:

Primer – Enhances adhesion to concrete substrate

Base Coat – Main body for strength and chemical resistance

Topcoat – Adds texture, gloss/matte finish, and antimicrobial or anti-slip properties

Professionally applied systems typically range between 2 mm to 5 mm in thickness, depending on traffic loads and functional needs.

Application Process: What to Expect

Proper application is key to maximizing the performance and lifespan of epoxy floor coatings in hospitals. Here’s a step-by-step overview of how professionals typically apply epoxy coatings in healthcare environments:

Step-by-Step Installation

Surface Preparation

- Remove all dust, oils, and contaminants.

- Shot blasting or diamond grinding may be used for mechanical profiling.

Crack & Joint Repair

Fill surface imperfections with epoxy patching compounds to ensure a smooth finish.

Primer Application

A primer is applied to seal pores and improve adhesion.

Base Coat

The epoxy resin mixture is poured and evenly distributed using rollers or squeegees.

Additives or Broadcast Materials

Anti-slip aggregates or decorative flakes can be added while the base coat is still wet.

Topcoat Application

A high-performance, chemical-resistant topcoat is applied for protection and finish.

Downtime & Curing

- Most systems require 24–48 hours to cure, depending on humidity and product type.

- Fast-curing formulas are available for quicker turnaround in emergency care settings.

Maintenance and Longevity Tips

One of the reasons epoxy floor coatings are preferred in hospitals is their ease of maintenance. Still, proper care ensures longevity.

Cleaning & Maintenance Best Practices

- Daily Cleaning: Use a soft-bristle auto-scrubber or microfiber mop with a neutral pH cleaner.

- Spot Cleaning: Immediately remove spills—especially acids, bodily fluids, or strong disinfectants.

- Avoid Harsh Tools: Do not use steel wool, wire brushes, or other abrasive cleaning tools.

- Routine Inspections: Look for signs of wear or topcoat degradation every 6–12 months.

With proper maintenance, epoxy flooring can last 10 to 15 years or more—even in high-traffic areas.

Frequently Asked Question

1. Why is epoxy flooring ideal for hospitals and healthcare facilities?

Epoxy flooring is seamless, non-porous, and easy to disinfect—making it perfect for infection control. It resists chemicals, stains, and impacts, ensuring long-lasting performance in sterile and high-traffic environments.

2. Where in a hospital can epoxy floor coatings be applied?

Epoxy coatings are suitable for operating rooms, ICUs, laboratories, corridors, pharmacies, waiting areas, kitchens, and even hospital basements. Their versatility and durability make them ideal for virtually any medical environment.

3. Is epoxy flooring safe for patients and staff?

Yes. Epoxy floors can be made slip-resistant and are low in VOC emissions, making them safe during and after installation. Their smooth surface also minimizes tripping hazards and helps maintain a sterile, easy-to-clean environment.

4. How long does epoxy floor installation take in a hospital setting?

Installation time depends on the size and condition of the area, but most hospital epoxy flooring projects can be completed within 2–5 days. Fast-curing options are available to reduce downtime and disruption to hospital operations.

5. How long does epoxy flooring last in a hospital?

With proper surface preparation and maintenance, epoxy floors can last 10–15 years or more—even under constant foot traffic and daily cleaning with harsh chemicals.

Conclusion

In healthcare, every detail contributes to the well-being of patients and staff. Epoxy floor coatings offer unmatched durability, hygiene, safety, and aesthetics, making them the top choice for hospitals aiming for both compliance and operational efficiency.

From operating rooms to kitchens, epoxy floors enhance cleanliness, reduce risks, and withstand the demanding conditions of medical environments. Investing in quality epoxy flooring is not just a facility upgrade—it’s a long-term contribution to health, safety, and cost-effective facility management.

If you're considering epoxy floor coating for your hospital or healthcare facility, trust the experts. Visit GZ Industrial Supplies to explore premium epoxy flooring solutions and get professional guidance tailored to your project needs.