Industrial Solvent Degreasers And Where They Are Needed

Introduction

Solvent degreasing is a fundamental industrial cleaning method used to dissolve and remove oil, grease, dirt, wax, solder flux, and other surface contaminants from metal parts and equipment. This is critical in industries such as automotive, aerospace, electronics, and metal fabrication, where parts must be pristine for optimal performance, further processing, or coating.

Industrial-grade solvent degreasers, like Epochem 530, penetrate and lift bound contaminants while simultaneously offering corrosion inhibition and controlled evaporation to enhance safety and cost-efficiency.

Read more...Benefits Of Using Industrial Cleaner And Degreaser

Epochem 530 Solvent degreaser 25 liters

Epochem 530 Solvent degreaser 25 liters

key takeaways:

-

Safe & Efficient Cleaning: Epochem 530 delivers strong oil and grease removal with a high flash point and low volatility, reducing fire risk and inhalation exposure during industrial degreasing processes

-

Eco-Friendly Formulation: Made from plant-based, non-toxic ingredients, Epochem 530 is biodegradable and non-hazardous, aligning with global shifts toward greener, low-VOC solvent alternatives.

-

Cost-Effective & Corrosion-Inhibitive: The solvent’s slow evaporation conserves solution volume, enhances cost efficiency, and provides temporary corrosion protection, simplifying maintenance protocols

Types of Solvent Degreasers

Understanding solvent classes is essential for selecting the correct degreaser based on contaminant type, substrate compatibility, safety, and environmental concerns.

Chlorinated Solvents

-

Includes trichloroethylene (TCE) and perchloroethylene (PCE).

-

Highly effective at dissolving stubborn oils and greases.

-

Major health concerns: carcinogenicity, toxicity affecting kidneys, liver, nervous and reproductive systems

-

Significant environmental and regulatory restrictions.

Petroleum-Based (Hydrocarbons)

-

Includes mineral spirits (“white spirit”) and kerosene.

-

Advantages: powerful solvency, widely available, cost-effective.

-

Drawbacks: flammability, VOC emissions, unpleasant odors, moderate health hazards such as skin/respiratory irritation.

Aromatic Solvents

-

Comprises toluene and xylene.

-

Delivers strong cleaning action, more potent than petroleum solvents.

-

Still presents fire risk, VOC emissions, and health hazards (irritation, potential long‑term effects).

Halogenated & Other Non-aqueous Solvents

-

Dichloromethane (a halomethane) is a common degreasing solvent due to low flammability and high volatility.

-

Vapor degreasing processes often utilize solvents like n-propyl bromide, which offer low flammability and residue-free cleaning.

Read more...WHERE TO BUY SOLVENT DEGREASERS IN NIGERIA

Engine Cleaner Epochem 520 Engine Degreaser 20 liters

Engine Cleaner Epochem 520 Engine Degreaser 20 liters

Comparative Selection

When selecting a solvent for industrial use, factors such as contaminant type, substrate compatibility, flash point, evaporation rate, toxicity, and environmental impact should be weighed.

Degreasing Application Processes

The method of application directly influences cleaning effectiveness, safety, and environmental performance:

Cold Solvent Cleaning

Involves spraying, brushing, or wiping solvent onto parts.

-

Pros: flexible, low-cost setup, minimal ventilation required.

-

Cons: solvent loss via evaporation, fire risk with low flash-point solvents.

Immersion (Tank) Cleaning

Parts are submerged in solvent tanks with agitation, then dried.

-

Pros: reaches complex geometries, efficient over bulk cleaning.

-

Cons: solvent emissions, disposal challenges, regulatory controls.

Vapor Degreasing

Parts are cleaned by solvent vapor condensation in an enclosed, heated chamber.

-

Pros: high cleanliness, ideal for electronics and precision parts, solvent recovery.

-

Cons: higher capital investment, potential exposure if not managed correctly.

Epochem 502 heavy duty degreaser and industrial cleaner

Epochem 502 heavy duty degreaser and industrial cleaner

Introducing Epochem 530 Solvent Degreaser

GZ Industrial Supplies, Nigeria, markets Epochem cleaning and maintenance chemicals, including Epochem 530 Solvent Degreaser .

Key Features

-

A plant-based, non-toxic, non-hazardous formula blending low-volatility, low-flammability solvents, emulsifiers, and corrosion inhibitors.

-

Engineered to penetrate heavy oil/grease, emulsify contaminants for easy removal, and provide temporary corrosion protection during evaporation.

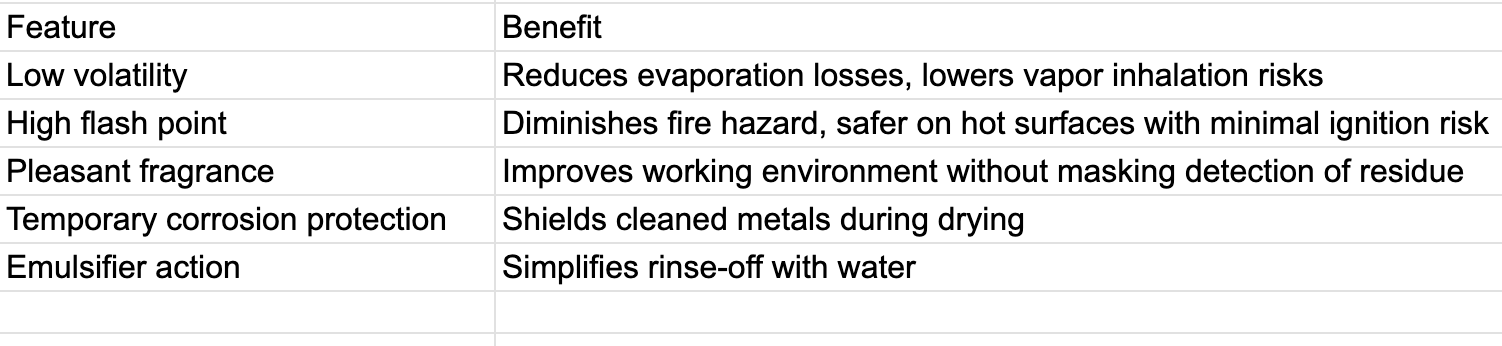

Performance & Safety Aspects of Epochem 530

These attributes make Epochem 530 efficient in degreasing operations while enhancing operator safety and cost-effectiveness.

Engine Cleaner Epochem 520 Engine Degreaser 5 liters

Engine Cleaner Epochem 520 Engine Degreaser 5 liters

Applications and Usage of Epochem 530

Epochem 530 excels across various industrial cleaning setups:

-

Vapor degreasing, cold batch immersions, manual spray-brush-wipe, or automated cleaning lines

-

Effective on engines, molds, dies, metal machine parts, tools, and surfaces needing oil/grease removal before painting, welding, or electronics assembly.

Choosing the Right Degreaser

Selecting the appropriate industrial solvent requires balancing performance, compatibility, safety, and cost:

Contaminant Type

-

Heavy oils or asphalt-like residues → strong hydrocarbon or chlorinated solvents like Epochem 530 or TCE PCE alternatives.

-

Light machining oils or fluxes → mild alternatives work well.

Material/Substrate Compatibility

-

Some solvents damage plastics or aluminum; plant-based non-aggressive options (e.g., Epochem 530) reduce chemical incompatibility.

Flash Point & Volatility

-

High flash point (low flammability) preferred for hot surfaces—Epochem 530 fits this requirement.

-

Low volatility reduces solvent loss and vapor inhalation.

Health & Environmental Impact

-

Avoid chlorinated or brominated solvents due to toxicity and changing regulatory landscapes

-

Favor greener options derived from plants or engineered for low VOC output.

Regulatory Compliance

EPA is increasingly restricting TCE, PCE, and methylene chloride; industries must switch to compliant solvents such as Epochem 530 or approved green alternatives.

Safety & Environmental Considerations

Health & Fire Safety

-

High flash-point, low-evaporation solvents like Epochem 530 minimize fire and inhalation risk.

-

Still requires basic PPE: gloves, goggles, and adequate ventilation.

Environmental Regulations

-

Solvents like TCE and PCE are being phased out due to health risks and ozone potential.

-

Non-toxic plant-based solvents are preferred—Epochem 530 is labeled non-hazardous and biodegradable.

Application Safety Practices

-

Use vapor degreasers with filtration and recovery for closed-loop solvent management.

-

Cold cleaning setups still need fume extraction and flammable solvent handling procedures.

Waste Disposal

-

Spent solvent must be taken to approved collection centers.

-

Spill containment systems and absorbents should be ready on-site.

Emerging Alternatives and Industry Trends

Green & Bio‑based Solvents

-

Derivatives like limonene, ethyl lactate, and fatty-acid methyl esters are gaining traction as sustainable replacements

-

Advantages include biodegradability, low toxicity, and low VOC emissions.

Non‑chlorinated Vapor Degreasing

-

Solvents such as n-propyl bromide and Bi-Solvent offer safer, chlorine-free options.

-

Best practice includes vacuum degreasers to eliminate emissions.

Advanced Solvent Recovery

Carbon adsorption and vacuum systems reclaim VOCs, reduce solvent loss, and improve compliance

Regulatory-Driven Change

EPA deadlines (like by mid-2025 for TCE) push industries to adopt safer compounds now.

Recommended brand: Epochem 530 in Nigerian Industry

A Nigerian fabrication plant struggled with engine and equipment cleaning, relying on hazardous low-flash solvents.

Challenge: Increase worker safety, meet regulation, lower costs from solvent loss.

Solution: Switched to Epochem 530 for both cold immersion and spray degreasing.

Results:

-

Safety: Reduced ignition risk, lower inhalation hazards thanks to low-volatility formula.

-

Efficiency: Emulsifiers improved removal; slower evaporation extended usable life.

-

Cost: Longer solvent life reduced reordering frequency.

-

Compliance: Aligned with emerging global restrictions on toxic solvents.

Related Articles

Benefits Of Using Industrial Cleaner And Degreaser

Epochem 502 Citrus Degreaser earns recertification for continued use in the oil and Gas Sector

Why Biodegradable Degreasers Are Changing Industrial Cleaning

Conclusion

Industrial solvent degreasers remain indispensable in demanding sectors such as automotive, aerospace, electronics, and metal fabrication. They ensure rapid, thorough removal of stubborn contaminants, supporting equipment performance, product quality, and strict regulatory compliance. However, the evolving landscape of health, safety, and environmental regulations increasingly demands safer and more sustainable cleaning solutions.

Epochem 530 Solvent Degreaser represents this new generation of industrial cleaners. It offers an exceptional balance between powerful performance and safety:

-

High flash point and low volatility — significantly reducing fire risks and emissions.

-

Plant-based, non-toxic formula — minimizing operator exposure and environmental impact.

-

Advanced emulsifier system — delivering effective contaminant breakdown and removal.

-

Temporary corrosion protection — providing added value during drying or transit.

The rise in global restrictions against solvents like TCE and PCE (notably the U.S. EPA’s ban on TCE effective January 16, 2025) makes green alternatives not only preferable, but essential.

Ready to upgrade to a safer, high-performance industrial degreaser? Explore Epochem 530 Solvent Degreaser today at GZ Industrial Supplies. Protect your equipment, your team, and the environment — all without compromising on cleaning power!