Maintaining and Sharpening Hand Tools

A hand tool is a tool that is powered by human muscle and/or gravity, as opposed to being powered by a motor. Hand tools are generally less expensive than power tools and are often favored by hobbyists and do-it-yourselfers because of their ease of use and versatility.

While hand tools are often less expensive than power tools, they can still be quite expensive, and it’s important to take the time to properly maintain and sharpen them so that they last a lifetime.

In this article, we’ll discuss the importance of maintaining and sharpening your hand tools, and we’ll provide you with a step-by-step guide on how to do it correctly.

8" crimp tool for open barrel pin and socket

Basic Tool Maintenance

One of the key aspects of prolonging the lifespan of your hand tools is proper maintenance. By regularly cleaning, storing, and lubricating your tools, you can ensure they stay in optimal condition. Here are some essential steps to follow:

1. Cleaning:

- After each use, remove any debris or dirt from your tools using a brush or cloth.

- For stubborn grime, use a mild detergent and warm water to clean the surfaces.

- Dry the tools thoroughly to prevent rust formation.

2. Storage:

- Store your hand tools in a clean, dry area to protect them from moisture and damage.

- Consider using toolboxes, racks, or pegboards to keep tools organized and easily accessible.

- Keep sharp tools separate from one another to avoid accidents and blade damage.

3. Lubrication:

- Apply a thin layer of lubricant, such as oil or grease, to metal parts to prevent rust and corrosion.

- Pay special attention to hinges, joints, and moving parts that may require regular lubrication.

- Wipe off any excess lubricant to avoid attracting dirt and debris.

"Regularly cleaning and lubricating your hand tools keeps them functioning optimally and extends their lifespan."

Remember to follow manufacturers' instructions for specific tool maintenance guidelines. Proper tool maintenance not only enhances their performance but also ensures your safety while using them.

? key Takeaway: Regular cleaning, proper storage, and lubrication are essential for maintaining and prolonging the lifespan of hand tools.

INGCO HTCS15591 59 PCS Tool Chest Set

Cleaning

Cleaning is an essential part of maintaining hand tools. It not only helps to remove dirt and debris but also prevents rust and corrosion. Here are some steps to follow when cleaning your hand tools:

1. Gather the necessary tools: Start by collecting a brush with stiff bristles, a cloth or sponge, mild soap, and water.

2. Remove dirt and grime: Use the brush to scrub away any dirt or grime on the surface of the tools. Pay extra attention to hard-to-reach areas and crevices.

3. Use soap and water: Fill a bucket or sink with warm water and add a few drops of mild soap. Dip the cloth or sponge into the soapy water and gently scrub the tools to remove any remaining dirt.

4. Dry the tools: Once the tools are clean, use a dry cloth to thoroughly dry them. Ensure that there is no moisture left on the surface, as this can lead to rusting.

5. Apply lubrication: After cleaning, it's a good idea to apply a thin coat of lubricant to the metal parts of your hand tools. This will help prevent rust and keep the tools moving smoothly.

Quote: "Regular cleaning of hand tools is crucial for their longevity and optimal performance."

? key Takeaway: Cleaning your hand tools regularly is essential to remove dirt, prevent rust, and maintain their longevity.

Bosch GFZ 16-35 AC Professional power hand saw

Storage

One of the key aspects of maintaining hand tools is proper storage. Storing your tools correctly helps prevent damage and keeps them ready for use. Here are some tips for effective tool storage:

1. Organize your tools: Keep your tools in a designated area where they can be easily accessed and organized. Consider using a toolbox, pegboard, or wall-mounted storage system to keep them neatly arranged.

2. Remove dirt and debris: Before storing your tools, ensure they are clean and free from any dirt or debris. Use a brush or cloth to wipe them down and remove any residue that could cause rust or deterioration.

3. Separate sharp and delicate tools: To prevent accidents or damage, separate sharp tools, such as chisels and knives, from delicate ones like measuring tools or precision instruments. Use protective sleeves or cases to keep them safe and prevent any potential injuries.

4. Protect against moisture: Moisture can lead to rust and corrosion, which can significantly reduce the lifespan of your tools. Store your tools in a dry area and consider using moisture-absorbing products, such as silica gel packs or dehumidifiers, to keep the environment dry.

5. Hang or store vertically: Whenever possible, hang your tools or store them in an upright position to prevent any bending or warping. This is especially important for saws and other long-handled tools that can easily become distorted if stored improperly.

6. Label and categorize: To make it easier to find the tool you need, label your storage areas and categorize your tools by type or function. Use clear containers or tool rolls to keep smaller items organized and easily accessible.

7. Regularly inspect and maintain: As you store your tools, make it a habit to inspect them for any signs of damage or wear. Address any issues promptly to ensure your tools are always in optimal condition.

Remember, proper storage is essential for maintaining the longevity and performance of your hand tools. By following these guidelines, you can keep your tools in excellent shape and ready to tackle any project.

? key Takeaway: Storing your hand tools properly is crucial for their longevity. Keep your tools organized, clean, and protected from moisture to ensure they stay in optimal condition. Regularly inspect and maintain them to address any issues promptly.

INGCO 117 PCS Tools Set HKTHP21171

Lubrication

Lubrication is a critical step in maintaining your hand tools and ensuring their optimal performance. By keeping your tools properly lubricated, you can prevent rust, reduce friction, and extend their lifespan. Here are some key tips for effective lubrication:

1. Choose the right lubricant: Different hand tools may require specific lubricants. For example, a light machine oil is suitable for hinges and pivot points, while silicone spray works well for moving parts that require a dry lubricant.

2. Apply the lubricant sparingly: Excess lubrication can attract dust and debris, creating more friction in the long run. Use a thin coat of lubricant, applying it directly to the necessary parts.

3. Focus on high-friction areas: Pay special attention to areas that experience the most wear and tear, such as joints, gears, and cutting edges. Apply lubricant to these areas regularly to ensure smooth operation.

4. Wipe off excess lubricant: After applying the lubricant, use a clean cloth to remove any excess. This helps prevent the accumulation of dirt and debris, which can hinder the performance of your tools.

Remember, proper lubrication is essential for maintaining the functionality and longevity of your hand tools. By following these tips, you can ensure that your tools operate smoothly and efficiently.

"Regular lubrication is key to maintaining the performance and lifespan of your hand tools."

Ingco Combination spanner set - (HKSPA1143)

Sharpening Tools

Properly sharpening your hand tools is essential for maintaining their effectiveness and prolonging their lifespan. Here are some key steps to follow when sharpening your tools:

1. **Choosing the Right Sharpener**: There are various types of sharpeners available, such as sharpening stones, honing guides, and sharpening jigs. Select the appropriate sharpener based on the type of tool and the level of precision required.

2. **Preparing the Tool**: Before you start sharpening, clean the tool to remove any dirt, debris, or rust. This will ensure a smooth sharpening process and prevent any damage to the tool's blade.

3. **Selecting the Proper Angle**: Different tools require different sharpening angles. Refer to the manufacturer's instructions or research the recommended angle for the specific tool you are sharpening. Use a sharpening jig or a honing guide to maintain a consistent angle.

4. **Sharpening Techniques**: There are various sharpening techniques, such as honing, grinding, or stropping. Understand which technique is suitable for your tool and apply it accordingly. Use steady and controlled movements to achieve a sharp and balanced edge.

5. **Testing the Sharpness**: After sharpening, check the sharpness of the tool's edge. Perform a simple test by lightly running your finger across the blade (with caution). If the blade easily catches on your finger, it indicates a sharp edge. Otherwise, continue sharpening until desired sharpness is achieved.

6. **Diagnosing Problems**: During the sharpening process, closely inspect the tool for any issues. Look for chips, cracks, or uneven wear on the blade. Identifying and addressing these issues early on can prevent further damage and improve the tool's performance.

7. **Common Tool Repairs**: If you notice any damaged components or parts during the sharpening process, it's important to repair or replace them. Examples of common repairs include replacing a handle, fixing a loose blade, or repairing a chipped edge.

8. **Safety Precautions**: When sharpening tools, always prioritize safety. Wear appropriate protective gear, such as safety goggles and gloves, to prevent injuries from flying debris. Ensure you have a secure working surface and maintain full control of the tool at all times.

Remember, the key to maintaining sharp hand tools is to regularly inspect, clean, and sharpen them as needed. By following these steps and adopting a proactive maintenance approach, you can

Bosch Spade chisels Hex 22 mm Self-sharpening (115 x 400mm) 2608690194

Types of Sharpeners

Choosing the right tool sharpener is essential for effectively maintaining and sharpening your hand tools. Here are some popular types of sharpeners:

1. Bench Stones: Bench stones, or whetstones, are versatile sharpening tools that come in various grits. Coarse grit stones (between 220 and 400) are ideal for quickly shaping the blade, while finer grit stones (between 1000 and 8000) are used for honing and polishing the edge.

2. Honing Guides: Honing guides are useful for maintaining consistent angles while sharpening. By securing the blade in the guide, you can easily maintain a precise edge without the risk of accidental changes in angle.

3. Sharpening Jigs: Sharpening jigs offer a hands-free sharpening experience by securely holding the tool against the sharpening surface. They are particularly useful for achieving consistent results when sharpening chisels and plane blades.

4. Electric Sharpeners: Electric sharpeners are efficient and convenient, making them a popular choice for quick sharpening tasks. They often come with adjustable guides and multiple sharpening stages to accommodate different blade angles and types.

? key Takeaway: Choosing the right sharpener for your hand tools is crucial in maintaining their sharpness and prolonging their lifespan. Bench stones, honing guides, sharpening jigs, and electric sharpeners each have their advantages and should be selected based on your specific needs and preferences.

Jig Saw 800W - INGCO JS80028

Sharpening Techniques

1. Choose the Right Angle: Different hand tools require different angles for sharpening. For example, chisels typically need to be sharpened at a 25 to 30-degree angle, while plane blades may require a slightly steeper angle of 30 to 35 degrees. It's crucial to understand the specific angle recommended for each tool to achieve optimal results.

2. Use a Sharpening Stone: A sharpening stone is a versatile tool for maintaining the sharpness of your hand tools. Start by moistening the stone with water or honing oil, then hold the tool firmly and glide it across the stone in a smooth and controlled motion. Repeat this process several times until you achieve a sharp edge.

3. Stropping for Finishing Touch: After using a sharpening stone, you can further refine the edge of your tool by stropping. Stropping involves rubbing the tool's blade against a leather or cloth strip charged with a polishing compound. This step helps remove any burrs and enhances the sharpness of the tool.

4. Honing Guides: To ensure consistent and accurate sharpening, consider using honing guides. These guides help maintain a consistent angle while sharpening and prevent unintentional variations. They are particularly useful for beginners who may find it challenging to hold a steady angle freehand.

5. Incremental Sharpening: If your tool's edge is excessively dull or damaged, it's best to approach sharpening in stages. Start with a coarser grit stone or file to remove larger imperfections, then move to progressively finer grits until you achieve the desired sharpness. This incremental approach ensures that you don't remove more material than necessary and preserve the integrity of the tool.

Quotes:"Proper sharpening techniques play a vital role in optimizing the performance and lifespan of your hand tools."

- Steps for sharpening different hand tools

- Necessary angles for sharpening different tools

- Recommended equipment for sharpening hand tools

? key Takeaway: Mastering the art of sharpening techniques is essential for maintaining the effectiveness of your hand tools. Adopting the correct angles, using sharpening stones and guides, and incorporating incremental sharpening ensure that your tools stay in top-notch condition for various tasks.

Torx Key INGCO HHK13091

Testing the Sharpness

Once you've sharpened your hand tools, it's important to test their sharpness before putting them to use. There are a few simple methods you can employ to ensure that your tools are in optimal condition.

1. The Paper Test:

Take a sheet of printer paper and hold it in one hand. With the other hand, try to cut through the paper using the edge of your tool. A sharp tool will slice through the paper smoothly, without snagging or tearing. If you notice any resistance or difficulty cutting through the paper, it's an indication that your tool needs further sharpening.

2. The Thumb Test:

With caution, gently run your thumb along the edge of the tool to feel for any imperfections or irregularities. A sharp tool should have a smooth, continuous edge without any nicks or rough spots. If you detect any roughness or unevenness along the edge, it's an indication that your tool needs sharpening.

3. The Visual Inspection:

Carefully examine the edge of your tool under a bright light source. A sharp tool will have a clean and polished edge, free from dullness or bluntness. If you notice any dull patches or rough edges, it's a sign that your tool requires sharpening.

Remember, it's essential to exercise caution while performing these tests to avoid any potential injuries. Always prioritize your safety and handle sharp tools with care.

? key Takeaway: Regularly testing the sharpness of your hand tools ensures optimal performance and allows you to identify when sharpening is needed. Using the paper test, thumb test, and visual inspection, you can determine if your tools are sharp enough for your tasks.

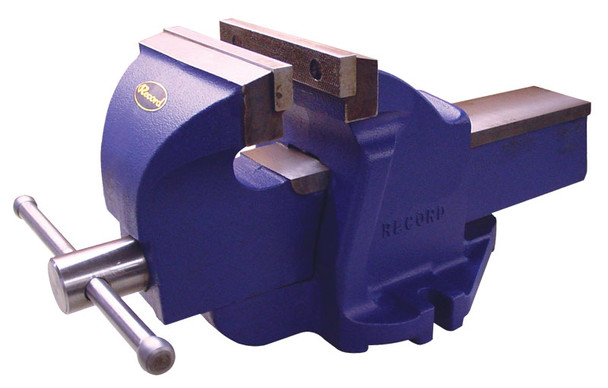

Record Bench Vice 8 inch Heavy duty made in England

Troubleshooting

Troubleshooting:

Sometimes, despite our best efforts, hand tools may encounter problems. Here are some common issues you may come across and how to diagnose and resolve them:

1. Dull Blades: If your tool's blades are not cutting as effectively as before, it's likely they need sharpening. Remember, dull blades can compromise the quality of your work and even pose safety risks. To solve this, use a sharpening stone or a dedicated blade sharpener to restore the edge. Follow the proper techniques for sharpening specific types of blades like knives, chisels, or saws.

2. Loose Handles: Loose handles can affect the stability and effectiveness of your hand tools. Inspect the tool to determine if it requires tightening or if the handle itself needs repair. Secure loose screws or bolts and apply wood glue if necessary. Always allow sufficient drying time before using the tool again to ensure a solid grip.

3. Rusty Surfaces: Exposure to moisture can lead to rust formation on metal surfaces. To address this, use a wire brush or sandpaper to gently remove the rust. Apply a rust-inhibiting spray or a light layer of oil to prevent further corrosion. Remember to wipe off excess oil before using the tool to avoid slippage.

4. Stuck Joints: Over time, joint mechanisms and hinges can become stiff or stuck due to debris or lack of lubrication. Use a degreaser or a specialized cleaner to remove dirt or grime. Once clean, apply a suitable lubricant such as WD-40 or silicone spray to ensure smooth movement and prevent future sticking.

? key Takeaway: Regular maintenance and troubleshooting are essential to keeping your hand tools in optimal condition. By promptly addressing issues like dull blades, loose handles, rust, and stuck joints, you can extend the lifespan of your tools and ensure their reliable performance.

Process Meter 789 Fluke

Diagnosing Problems

When it comes to hand tools, it's important to be able to identify any potential issues or malfunctions. Here are some common problems you may encounter and how to diagnose them:

1. Dull or Blunt Edges: Over time, the cutting edges of hand tools can become dull and less effective. If you're experiencing difficulty in cutting or carving, it may be due to dull edges. Inspect the tool closely and check for signs of wear or damage. A dull edge will often have visible nicks, chips, or rounded corners.

2. Rust or Corrosion: Exposure to moisture can lead to rust or corrosion on metal hand tools. Inspect your tools regularly for any signs of rust, such as reddish-brown spots or flaking on the surface. Rust can affect the performance and longevity of your tools if left unattended.

3. Loose Handles: Handles that are loose or wobbly can be a safety hazard and can also reduce the efficiency of your tools. Check the connection between the handle and the tool head. If there is noticeable movement or play, it may be necessary to tighten or replace the handle.

4. Bent Blades or Prongs: Hand tools with bent blades or prongs can be less effective or even dangerous to use. Examine the tool for any signs of bending, warping, or misalignment. If you find any such issues, it's important to address them promptly to ensure proper functioning.

5. Stuck or Jammed Mechanisms: Some hand tools, such as pliers or adjustable wrenches, have movable parts or mechanisms. If you find that these mechanisms are not moving smoothly or are stuck in place, it may be a sign of debris buildup, wear and tear, or even a need for lubrication.

? key Takeaway: Diagnosing problems with hand tools is essential for maintaining their performance and safety. Regular inspections can help identify issues such as dull edges, rust, loose handles, bent blades, and stuck mechanisms. By promptly addressing these problems, you can ensure that your tools are functioning optimally.

Flir E60 Thermal imaging camera

Common Tool Repairs

When it comes to maintaining and sharpening hand tools, understanding common repairs is essential. Here are some frequently encountered issues and their corresponding solutions:

1. Loose Handles:

- Inspect the tool handles for any splits or cracks.

- If the handle is loose, remove it carefully.

- Apply wood glue to the joint and press the handle firmly back into place.

- Secure the handle using clamps and allow the glue to dry completely before using the tool again.

2. Dull Blades:

- Examine the cutting edge of the blade to determine its level of sharpness.

- If the blade is dull, you can use a variety of sharpening techniques to restore its edge, such as honing with a sharpening stone or using a sharpening jig.

- Follow the manufacturer's instructions or seek guidance from a knowledgeable source to ensure proper sharpening.

3. Rust Removal:

- Rust can compromise the performance of your hand tools; therefore, it's essential to address it promptly.

- Apply a rust remover or a mixture of vinegar and water to the affected area.

- Use steel wool or a wire brush to gently scrub off the rust.

- Wipe the tool dry and apply a light coat of oil to prevent future rusting.

4. Stuck or Jammed Mechanisms:

- If a mechanism on your hand tool is stuck or jammed, it may require cleaning and lubrication.

- Disassemble the tool as much as possible, keeping track of each part.

- Clean each piece thoroughly with a brush and a suitable cleaning solution.

- Lubricate the moving parts with a lubricant appropriate for the specific tool.

- Reassemble the tool carefully, ensuring proper alignment and functionality.

? key Takeaway: Regular maintenance and proper repairs are essential to keep your hand tools in top condition. By addressing common issues such as loose handles, dull blades, rust, and stuck mechanisms, you can extend the lifespan of your tools and ensure optimal performance.

Ingco HKSPA3088 Offset Ring Spanner 8-Pieces Set, 6-22 mm Size

Tool Safety

When it comes to working with hand tools, prioritizing safety is of utmost importance. Taking proper precautions and using the right protective gear can help prevent accidents and injuries. Here are some key safety measures to keep in mind while using hand tools:

1. Personal Protective Equipment (PPE): Always wear the appropriate PPE, such as safety goggles, gloves, and ear protection, depending on the specific tool and task at hand. PPE helps shield you from flying debris, sharp edges, and loud noises.

2. Proper Tool Handling: Handle tools with care and maintain a firm grip while using them. Avoid rushing or using excessive force, as this can lead to accidents. Always grip tools firmly, ensuring they won't slip out of your hand during use.

3. Secure Work Area: Before starting any work, ensure your work area is clean, well-organized, and free from clutter. This helps minimize the risk of tripping over tools or materials, reducing the chances of accidents.

4. Regular Inspections: Inspect your hand tools regularly for any signs of damage, wear, or loose parts. Ensure all handles are securely fastened and without cracks. If you notice any issues, either repair or replace the tool promptly.

5. Proper Tool Storage: Store your hand tools in a designated area, keeping them organized and easily accessible. Use toolboxes, racks, or wall-mounted storage systems to prevent tools from getting damaged or causing harm to others.

6. Sharp Blades: Keep your blades sharp to avoid applying excessive force during use. Dull blades can slip or cause uneven cuts, increasing the risk of accidents. Regularly inspect and sharpen blades using the appropriate sharpening techniques and tools.

? key Takeaway: Prioritize safety when using hand tools by wearing appropriate protective gear, handling tools with care, maintaining a secure work area, regularly inspecting tools for damage, and ensuring blades are sharp.

8pcs Handtools Set INGCO HKTH10808

Safety Precautions

When it comes to maintaining and sharpening hand tools, safety should always be a top priority. By following proper safety precautions, you can prevent accidents and ensure a smooth and successful maintenance process. Here are some important safety guidelines to keep in mind:

1. Wear protective gear: Before you begin any maintenance or sharpening activities, make sure to wear the appropriate protective gear. This includes safety goggles to protect your eyes from flying debris, gloves to protect your hands from cuts and abrasions, and ear protection if you will be working with loud tools.

2. Work in a well-ventilated area: Whether you are cleaning, lubricating, or sharpening your hand tools, it is important to do so in a well-ventilated area. This will help to prevent the inhalation of potentially harmful fumes or particles.

3. Use proper tool handling techniques: Be mindful of how you handle your hand tools. Always grip them firmly and avoid applying excessive force or pressure, as this can lead to accidents or tool breakage.

4. Sharpen tools on stable surfaces: When sharpening your hand tools, it is crucial to work on a stable and secure surface. Avoid sharpening tools on uneven or wobbly surfaces to maintain control and prevent accidents.

5. Follow manufacturer instructions: Different hand tools may have specific guidelines for maintenance and sharpening. Always refer to the manufacturer's instructions for any special considerations or recommendations.

6. Keep tools out of reach: After completing your maintenance or sharpening tasks, ensure that your hand tools are safely stored and kept out of reach of children or inexperienced individuals. This will help prevent accidents and injuries.

? key Takeaway: Prioritizing safety is essential when maintaining and sharpening hand tools. Wear protective gear, work in a well-ventilated area, use proper tool handling techniques, sharpen tools on stable surfaces, follow manufacturer instructions, and keep tools out of reach to ensure a safe and successful maintenance process.

Fire Resistant Coverall

Protective Gear

When it comes to maintaining and sharpening hand tools, it's crucial to prioritize your safety. Wearing the appropriate protective gear will help minimize the risks of accidents or injuries. Here are some essential items to consider:

1. Safety Glasses: Protect your eyes from flying debris, sparks, or any potential hazards that may occur during the maintenance process.

2. Gloves: Invest in a good quality pair of work gloves to shield your hands from cuts, abrasions, or any harsh chemicals you may encounter while cleaning or lubricating your tools.

3. Dust Mask: When sharpening tools, especially those made of metals like steel or iron, fine particles and dust can be released into the air, which can be harmful if inhaled. Wearing a dust mask will help filter out these particles and protect your respiratory system.

4. Ear Protection: Some tools, when being sharpened or repaired, can produce loud noises that may damage your hearing over time. Earmuffs or earplugs can help reduce the decibel levels and safeguard your ears.

5. Protective Clothing: It's advisable to wear long sleeves and pants to provide an additional layer of protection against cuts, abrasions, or any potential mishaps during the maintenance process.

Remember, safety should never be compromised. Prioritize your well-being by wearing the proper protective gear when handling hand tools.

? key Takeaway: Wearing the appropriate protective gear is essential when maintaining and sharpening hand tools to ensure your safety and minimize the risk of accidents or injuries.

24 Pcs 1/2" Socket Set INGCO HKTS0243

Conclusion

Properly maintaining your hand tools will prolong their lifespan and make your job easier. Follow these tips to keep your tools in top shape.

1. Keep your tools clean: Clean your tools after use with a damp cloth or sponge.

2. Keep them sharp: Sharpen your tools regularly to keep them sharp and accurate.

3. Store them properly: Keep your tools in a safe and dry place.

4. Use them properly: Use your tools for the intended purpose.

Elevate Your Tool Performance with GZ Industrial Supplies Nigeria

Keep your hand tools functioning at their best! Proper maintenance and sharpening are crucial to extending the life and efficiency of your tools. At GZ Industrial Supplies Nigeria, we offer top-tier solutions and products designed to keep your hand tools in peak condition. Whether you're a seasoned professional or a passionate hobbyist, our range of maintenance and sharpening tools ensures your gear remains sharp, durable, and ready for any task.

Don't compromise on the quality and performance of your hand tools. Visit us at gz-supplies.com or reach out directly at sales@gz-supplies.com to explore our comprehensive maintenance solutions. With GZ Industrial Supplies Nigeria, you're not just buying products; you're investing in the longevity and efficiency of your tools. Contact us today and experience the difference that well-maintained hand tools can make in your projects.

Related Articles