The Best Industrial Hoses For oil and gas industry

Introduction

Industrial hoses are a vital component in the oil and gas industry, serving as the lifeline for transporting fluids, gases, and other critical materials under high pressure and extreme environmental conditions. From upstream drilling rigs to downstream refineries, hoses ensure safe and efficient operations in a sector where even the slightest failure can result in costly downtime or catastrophic hazards.

In this guide, we explore the industrial hoses in oil and gas: what they are, why they're essential, and how to choose the right ones for your operation.

This hose crimping machine DX68 is designed for crimping rubber hoses with steel wire reinforcement (up to 2 layers), it ensures leak-free connections critical for hydraulic systems in drilling rigs, refineries, and offshore equipment. With its compact design, strong 449T crimping force, and precision scale adjustment (±0.02mm), this machine allows for quick, accurate, and safe crimping even on large or irregular fittings. It operates quietly and efficiently, making it ideal for field use or workshop environments.

Key Takeaways

- Industrial hoses are critical for safely transferring hydrocarbons, chemicals, steam, and gas in oil and gas operations.

- Choosing the right hose involves understanding pressure, temperature, compatibility, and safety certifications.

- Proper maintenance and regular inspection are essential to prevent downtime and ensure compliance with industry standards.

What Are Industrial Hoses?

Industrial hoses are flexible or semi-rigid tubes made from durable materials designed to transport liquids, gases, and solids. They typically consist of three layers:

- Inner tube: Directly contacts the conveyed material and is resistant to chemical or thermal degradation.

- Reinforcement layer: Provides the necessary strength to withstand pressure, vibration, and external stress.

- Outer cover: Shields the hose from abrasion, UV rays, chemicals, and mechanical wear.

These hoses vary by function: some are designed for suction (drawing fluid in), others for discharge (expelling it), and some do both.

This hose crimping machine DF68 empowers technicians in the oil and gas sector to assemble and crimp hydraulic hoses on-site, minimizing downtime and eliminating the need for off-site servicing.

Ideal for crimping hose sizes from 1/4" to 2", this semi-automatic machine delivers 449 tons of crimping force, ensuring secure and leak-proof fittings for high-pressure systems. With 10 die sets (16–63mm) included, it accommodates a wide range of hose sizes commonly used in drilling, pipeline maintenance, and industrial hydraulics. Compact, quiet, and user-friendly, the DF68 is perfect for both workshop and field use. Certified by CE and ISO, and backed by a 3-year warranty, it's a durable and dependable solution for demanding environments.

Why Specialized Hoses Are Crucial for Oil & Gas

The oil and gas environment is among the harshest. Hoses are often exposed to:

- High temperatures and extreme pressures

- Corrosive chemicals and hydrocarbons

- Abrasive solids and sand

- Risk of explosion due to static discharge or gas leaks

Using general-purpose hoses in these conditions is not only inefficient but dangerous. This is why oil and gas hoses are built to meet stringent industry standards, including API 7K, API 16C, ISO 1823, and more.

Key risks that specialized hoses mitigate include:

- Hose bursting under pressure

- Rapid chemical degradation

- Electrical hazards in flammable environments

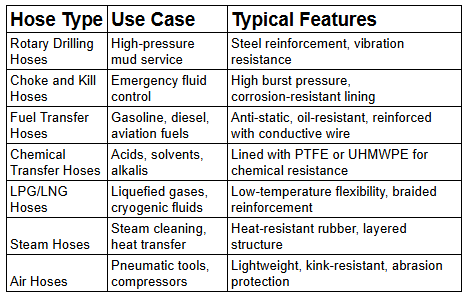

Types of Industrial Hoses Used in Oil and Gas

Key Applications of Industrial Hoses in Oil and Gas

Industrial hoses are deployed at every stage of oil and gas operations, from exploration to refining. Here are the most critical areas where they are indispensable:

1. Upstream – Drilling and Extraction

- Rotary drilling hoses deliver drilling mud between the mud pump and the drill string.

- Choke and kill hoses are used during pressure control in wellbore operations.

- Hoses handle cementing, acidizing, and stimulation fluids in onshore and offshore wells.

2. Midstream – Transportation and Storage

- Fuel transfer hoses connect tank trucks to storage tanks, marine vessels, or pipelines.

- Vapor recovery hoses help in capturing volatile gases during fuel transfer operations.

- In LNG terminals, cryogenic hoses transfer liquefied gases safely under sub-zero conditions.

3. Downstream – Refining and Distribution

- Chemical hoses transport aggressive refining chemicals and cleaning agents.

- Steam hoses assist with thermal cleaning and heat exchange in refineries.

- Hoses used in loading arms and manifolds help in bulk fuel loading into tanker ships or railcars.

4. Support Services and Maintenance

- Compressed air hoses power pneumatic tools used in construction and maintenance.

- Water hoses are used for hydroblasting, cleaning tanks, and controlling dust.

- Degassing and flushing hoses are employed to clean pipelines and equipment before maintenance.

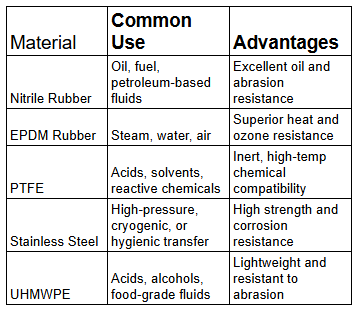

Materials and Construction Standards

Industrial hoses must comply with international safety and performance standards. These standards guide the selection of materials and construction based on the hose's application:

Common construction includes:

- Braided steel wire reinforcement (for pressure resistance)

- Helix wire (for suction and flexibility)

- Anti-static layers (to prevent sparking in flammable environments)

The HP51 KAIDA Hydraulic Hose Crimping Machine is a powerful and precise solution for assembling high-pressure rubber hoses in demanding sectors like oil and gas, mechanical engineering, and heavy equipment maintenance.

With a compact and portable design, the HP51 KAIDA delivers high crimping force, operates with low noise, and allows for accurate buckling adjustments via an integrated precision scale. Its eight-flap mould seat with a high-accuracy guide system ensures even pressure distribution during crimping—ideal for securing fittings under high-pressure conditions. Powered by 4KVA and compatible with 220–415V, this machine is engineered for reliability, flexibility, and ease of use in both field and workshop environments.

Maintenance Best Practices for Industrial Hoses

Neglecting proper care of industrial hoses can lead to failure, downtime, and safety hazards. Here are essential tips to extend their lifespan:

Regular Inspection

- Look for cracks, bulges, or leaks.

- Inspect end fittings for corrosion or loosening.

- Rotate hoses periodically to even out wear.

Proper Storage

- Store hoses in a cool, dry area away from direct sunlight.

- Use hose reels or racks to prevent kinks and deformation.

- Never hang hoses by the fittings.

Cleaning and Flushing

- Flush hoses regularly to prevent residue buildup.

- Use appropriate cleaning agents compatible with hose material.

- After hydrocarbon transfer, purge hoses with nitrogen or air to remove vapors.

How to Choose the Right Hose for Oil and Gas Applications

Choosing the right industrial hose can significantly improve safety and operational efficiency. Use the STAMPED method for proper hose selection:

Why It Matters: Safety, Performance, and Compliance

The right industrial hose:

- Minimizes the risk of blowouts and leaks in hazardous environments.

- Prevents costly downtime by ensuring consistent product flow.

- Ensures compliance with OSHA and API (American Petroleum Institute) standards.

Frequently Asked Questions

1. What types of industrial hoses are best suited for oil and gas applications?

The most suitable hoses include composite hoses, stainless steel braided hoses, rubber hoses, and thermoplastic hoses. Each is designed for specific tasks such as fuel transfer, chemical handling, steam, or hydraulic systems, with high resistance to pressure, temperature, and corrosive substances.

2. How do I choose the right hose for my oil and gas operation?

Selecting the right hose depends on the media being transported (oil, gas, chemicals), temperature range, pressure rating, and environmental conditions. Always consider compatibility with fluids, flexibility needs, abrasion resistance, and industry compliance (API, ISO, or OSHA).

3. Are industrial hoses for oil and gas resistant to harsh environments?

Yes. High-quality industrial hoses are engineered to withstand extreme temperatures, UV exposure, saltwater corrosion, chemical spills, and high-pressure conditions, making them ideal for onshore and offshore oil and gas operations.

4. How often should oil and gas hoses be inspected or replaced?

Hoses should be visually inspected before each use and undergo scheduled preventive maintenance checks monthly or quarterly, depending on the intensity of usage. Replacement is recommended at the first sign of wear, cracking, or pressure drop, or after the manufacturer's recommended service life.

5. What certifications or standards should industrial hoses meet in the oil and gas sector?

Industrial hoses should comply with industry-specific standards like API (American Petroleum Institute), ISO 9001, EN 13765/13766, and OSHA safety guidelines. Certification ensures the hose meets performance, safety, and environmental requirements for oil and gas operations.

Related Articles

Conclusions

Industrial hoses are not just accessories, they’re vital components in the oil and gas industry's infrastructure. Whether it's for upstream well servicing, midstream fuel transfer, or downstream refinery operations, choosing high-performance, industry-rated hoses ensures operational efficiency, worker safety, and environmental protection.

If you’re in Nigeria and need expert guidance or a reliable supplier of premium oil and gas industrial hoses, contact GZ Industrial Supplies, Tikweld Products and Services, or Epoxy Oilserv Nigeria Ltd. These trusted distributors stock a wide range of certified hoses tailored to meet the extreme demands of oil and gas operations. Visit GZ Industrial Supplies to explore the best industrial hose options for your application.