Types of Grease to Use on a Grease Gun

Introduction

Lubrication is at the heart of machine maintenance, and when it comes to efficiently applying grease in automotive, industrial, and construction settings, grease guns are indispensable. However, using the wrong type of grease can lead to equipment failure, downtime, and added repair costs.

This article helps you understand which greases are best suited for grease guns and why the right combination makes all the difference.

Read more...How to Load a Grease Gun Without a Mess

Key Takeaway

- Grease Selection Depends on Application:Different equipment requires specific grease types. Always match grease properties (viscosity, load-carrying ability, temperature tolerance) with the machinery’s needs.

- Lithium-Based Grease Is the Most Common:Ideal for general-purpose use in automotive, industrial, and farm equipment due to its good temperature resistance and water tolerance.

- Calcium-Based Grease Offers Excellent Water Resistance:Suitable for marine and wet environments but has a lower heat tolerance than lithium grease.

- Polyurea Grease Provides Long Service Life:Often used in sealed-for-life bearings because of its superior oxidation resistance and high-temperature stability.

What Makes a Grease Suitable for a Grease Gun?

Before diving into the types of grease, it’s crucial to understand what makes a grease compatible with grease guns:

- NLGI Grade: Grease consistency must be pumpable; NLGI Grade 2 is most common.

- Base Oil Type: Mineral, synthetic, or vegetable-based oils influence application temperature and performance.

- Additives: Anti-wear, anti-oxidation, and water-resistant additives enhance performance.

- Drop Point: Indicates the temperature at which grease begins to liquefy; higher is better for heavy-duty tasks.

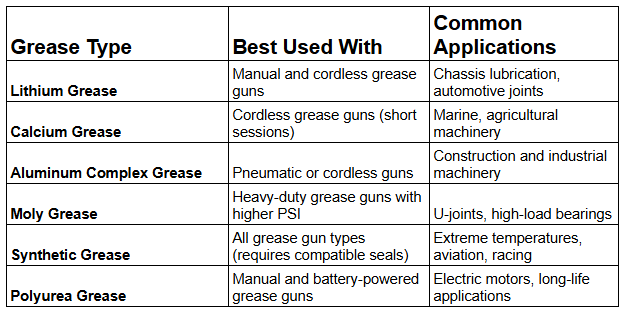

Common Types of Grease Used in Grease Guns

- Lithium Grease: The most commonly used, offers great temperature tolerance, water resistance, and general-purpose performance.

- Calcium Grease: Excellent water resistance but limited temperature stability; best for marine applications.

- Aluminum Complex Grease: High-temperature capability and excellent rust resistance; ideal for heavy industrial equipment.

- Molybdenum (Moly) Grease: Contains moly particles for high-pressure applications like bearings or joints.

- Synthetic Grease: Superior performance in extreme temperatures and long-life applications.

- Polyurea Grease: Known for excellent oxidation resistance and is often used in sealed-for-life bearings.

Read more...Can Multi-Purpose Grease be used On Wheel Bearings?

Recommended Brand:

DongCheng Cordless Grease Gun – DCGG500

GZ Industrial Supplies is the distributor and supplier of DongCheng Power Tools in Nigeria. One standout model is the DongCheng Cordless Grease Gun DCGG500, perfect for confined areas or professional-grade maintenance.

Why It Stands Out:

- Pressure control system and relief valve for safety.

- Ultra-high 10,000 PSI oil injection pipe.

- Two-speed control for versatile application needs.

Specifications:

- Battery: 20VMAX/2.0Ah

- Max Pressure: 10,000 PSI

- Oil Injection Rate: 170g/min (high), 110g/min (low)

- Hose Length: 800mm

- Tank Capacity: 500cc

- Weight: 3.2kg

Read more...Grease Guns in Nigeria: Complete Buyer’s Guide & Usage Tips

Matching the Right Grease with Your Grease Gun

Not all grease guns handle all types of grease well. Understanding the synergy between the tool and the lubricant ensures optimal performance:

Tip: Always check your equipment’s manual or manufacturer's recommendation to select the correct grease formulation and NLGI grade.

Application Tips: Getting the Most Out of Your Grease Gun

Whether you're using the DongCheng Cordless Grease Gun – DCGG500 or another model, best practices help maximize lubrication efficiency:

- Purge Air Before Use: Prevents gaps in grease flow.

- Use Clean Grease: Contaminants can damage fittings and bearings.

- Monitor Pressure: Excess pressure can rupture seals.

- Grease Regularly: Follow a preventive maintenance schedule.

- Label Grease Guns: If you use multiple greases, color-code the guns to avoid cross-contamination.

Using your grease gun properly not only extends equipment life but also ensures safety and cost-effectiveness in the long run.

Frequently Asked Questions

1. Can I mix different types of grease in my grease gun?

No. Mixing greases, especially with different thickeners (e.g., lithium vs. calcium), can lead to incompatibility, resulting in oil separation, hardening, or ineffective lubrication.

2. How do I know which grease to use for my machinery?

Always refer to the equipment manufacturer’s manual. Most will specify the recommended NLGI grade and base type (lithium, calcium, etc.).

3. What NLGI grade is most common for grease guns?

NLGI Grade 2 is standard for most manual and cordless grease guns. It's thick enough to stay in place but flows under pressure.

4. Is red grease a special type?

No. “Red” refers to the dye used. Red lithium grease, for example, is colored for visual identification but does not indicate special formulation.

5. Can DongCheng Cordless Grease Gun handle different greases?

Yes. The DongCheng DCGG500 can accommodate various types including lithium, calcium, and aluminum complex greases, making it versatile for multiple industrial applications.

Related Article

Grease Guns in Nigeria: Complete Buyer’s Guide & Usage Tips

WHERE TO BUY INDUSTRIAL LUBRICANT IN NIGERIA

Proper Grease Selection for Marine Equipment

Conclusion

Choosing the right grease for your grease gun isn’t just about lubrication—it’s about maximizing performance, preventing wear, and extending the lifespan of your equipment. Whether you're maintaining industrial machinery, automotive systems, or agricultural tools, using the correct type of grease ensures smoother operation, reduced downtime, and long-term savings.

From lithium-based to moly and synthetic greases, always match the grease type to your equipment's specific needs—and don’t forget to follow manufacturer recommendations and avoid grease mixing.

Ready to stock up on premium grease for your tools and machinery? Visit GZ Industrial Supplies to explore our wide selection of high-quality greases, grease guns, and maintenance accessories. Equip your workshop with products trusted by professionals across Nigeria.