Proper Grease Selection for Marine Equipment

Proper Grease Selection in Marine Equipmen

Background Description of grease

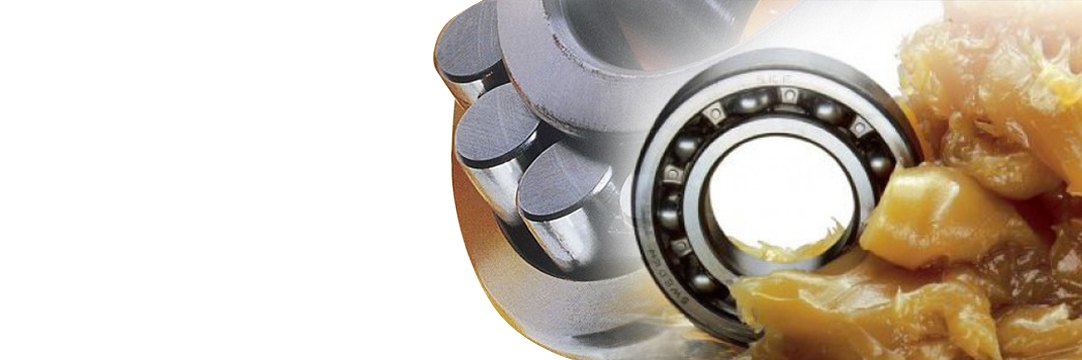

It is gradually becoming an imperative to make a proper grease selection for marine equipment if marine equipment are expected to last as long as the manufacturer OEM had specified, Grease is a solid to semi-solid product of dispersion of a thickening agent in a liquid lubricant, writes Machinery Lubrication.

Marine Grease is an NLGI (National Lubrication Grease Institute) 2 multi-purpose lithium complex grease with high temperature and gummy in nature. It contains a special anti-rust additive for enhanced protection against rust and corrosion in marine and salt water environments. It also contains tackiness additives to allow it to stay in place providing excellent water resistance and shock loading under all operating conditions.

The function of grease is to remain in contact with and lubricate moving surfaces without leaking out under the force of gravity, centrifugal action or being squeezed out under pressure. Its major practical requirement is that it retains its properties under shear forces at all temperatures it experiences during use.

APPLICATION

Grease is used when it is not practical or convenient to use oil. The lubricant choice for a specific application is determined by matching the machinery design and operating conditions with desired lubricant characteristics. Grease maintains thicker films in clearances enlarged by wear and can extend the life of worn parts that were previously lubricated by oil.

Improper selection and application of the proper type of grease to perform in the intended application is one of the biggest reasons for failure. Also at the top of the list is grease compatibility or the lack of it. As a general rule, keep similar thickeners in the same application (e.g., lithium with lithium complex). If possible, do not mix greases of different thickener types. Shortage of grease in any equipment can cause failure, likewise too much of it can as well result to failure because excessive lubricant causes high temperatures, which in turn oxidizes the grease.

CHARACTERISTICS

Some of the major characteristics that must be considered when selecting grease for an application, are as follows;

The pumpability, water resistance, dropping point, oxidation stability, high-temperature effects, low-temperature effects.

Grease consistency depends on the type and amount of thickener used and the viscosity of its base oil. A grease's consistency is its resistance to deformation by an applied force. The measure of consistency is called penetration. Penetration depends on whether the consistency has been altered by handling or working. ASTM D 217 and D 1403 methods measure penetration of unworked and worked greases. To measure penetration, a cone of given weight is allowed to sink into a grease for five seconds at a standard temperature of 25°C (77°F).

There are three essential components that form lubricating grease. These components are base oil, thickener and additives. The base oil and additive package are the major components in grease formulations, and as such, exert considerable influence on the behavior of the grease.

Base Oil

Grease is formulated with up to 95 percent base oil. Most greases today use mineral oil as their fluid components. These mineral oil-based greases typically provide satisfactory performance in most industrial applications. In temperature extremes (low or high), a grease that utilizes a synthetic base oil will offer better stability.

Thickener

The thickener is a material that will produce the solid to semifluid structure in combination with the selected lubricant. The primary types of thickeners used in grease are metallic soaps. These soaps include lithium, aluminum, clay, sodium and calcium. Lately, complex thickener-type greases are gaining popularity. They are being selected because of their high dropping points and excellent load-carrying abilities.

Additives

Additives can play several roles in a lubricating grease. These primarily include enhancing the existing desirable properties, suppressing the existing undesirable properties and imparting new properties. The most common additives are oxidation and rust inhibitors, extreme pressure, anti-wear and friction-reducing agents.

A grease must possess the ability to form a film of lubricant which is not easily removed and which may be required to resist shock loading, it must also be able to resist temperature rises without becoming softened unduly in the process

TYPES OF GREASE

Greases are primarily classified by their thickeners, the most common being metallic soaps. Others include bentonite clay, silica gel, polyurea and inorganic thickeners.

Soap‑based greases are produced from three main ingredients. One is the fatty material (animal or vegetable), which is usually 4 to 15 percent of the total, called the acid. The next is the base or alkali, which is the opposite of an acid.

LITHIUM GREASE: Lithium grease has excellent resistance to water and breakdown, or softening, by working. Pumpability is a very strong characteristic for this type of grease. Lithium grease consist of improved performance in the area of high temperature, high speed bearing life. Dropping point is approximately 500°F.

CALCIUM GREASE: Calcium Grease is one of the first types of grease manufactured. Used today largely because they are moderately priced. It is manufactured by using hydrated lime and a fatty material. Calcium grease must be used in a lower temperature environment, since they are limited to approximately 150°F. Higher temperatures may alter the grease structure. It has very good water tolerance.

POLYUREA GREASE: This is a grease of fairly recent development that does not use a conventional soap thickener. This type of grease has a high dropping point, approximately 470°F, has an ashless structure, excellent water resistance, pumpability and provides superb high temperature bearing life.

INORGANIC THICKENERS: Inorganic thickeners such as clay and silica consist of spheres and platelets. They thicken fluids with their large surface area. These products produce a very smooth non-melting grease that can be made to perform very well when careful consideration is given to product application.

Also make sure about compatibility, because greases are a complex mixture of balanced chemicals, there's potential for issues if you try to mix different greases in the same place, and this is especially true when high temperatures are involved. You know this is happening to you if the grease you just added thins out too quickly. This problem is typically solved by adding more grease until the old residual grease is flushed out.

But if that isn't an option, there's not much choice other than dismantling the equipment and cleaning it out. While the only exact way to avoid this problem is to test every grease you plan to use, the general rule is that there's less potential for problems if you stay within the same faily of thickener (lithium to lithium, lithium complex to lithium complex, aluminum complex to aluminum complex, etc.).

GREASE BRANDS

There are several brands of greases that are formulated to meet customer needs. Most popular are the Shell brands of greases which is known as Shell Gadus. The Shell Gadus range of greases offers protection across a wide range of applications. For example, Shell Gadus S2 V220 2 grease,High performance, multipurpose extreme pressure grease, Shell Gadus S2 V220AD 2, High performance heavy duty grease containing solid lubricants, Shell Gadus S3 V220C 2, Top-performance, high-temperature, extreme-pressure multipurpose grease, Shell Gadus S3 T220 2 Ultimate performance extreme pressure di-urea grease, Shell Gadus S3 V460D, Shell Gadus S5 V100 2 Advanced multipurpose grease. Other brands of grease are Total Ceran AD Plus, Total Bioadhesive Plus, Total Ceran XM 220, Total Biomul TIS EP 2, Total Ceran WR 2, Castrol Bio TAC MP and Castrol Spheerol SX2.

Using the right grease for your needs can deliver significant savings. To find the right grease for your machinery please visit GZ industrial supplies The Grease Shop Nigeria, for all brands of quality greases that are designed to help your equipment continue to operate without disruption.

GREASE ANALYSIS

Grease analysis is helpful not only for determining the condition of the lubricant, but especially for discovering abnormal conditions in equipment that may otherwise lead to unexpected failure. Grease sample testing is supported by an experienced team of consultants, who are members of the SAE, NLGI and EI grease committees and can advise on test method selection and interpretation of results. Grease analysis is aimed at providing valuable insight into grease performance and integrity.

CONCLUSION

The term grease is used to describe semisolid lubricants. The characteristic feature of grease is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. When selecting a grease, you must consider the application and operating conditions in which the grease will function. For a better understanding of what goes into a good grease, it is essential to concentrate on its components, including the base oil type, thickener type, base oil viscosity and the NLGI Grade.

Grease functions as a sealant to prevent lubricant leakage and also to prevent entrance of corrosive contaminants and foreign materials. It also acts to keep deteriorated seals effective. It is often applied using a grease gun, which applies the grease to the part lubricated under pressure, forcing the solid grease into the spaces in the part.

The

NLGI (National Lubricating Grease Institute) has standardized a

numerical scale for grease consistency based upon ASTM D 217 worked

penetration ranging from 000 for semifluid to 6 for block greases.

please select your grease from our The Grease shop Nigeria