What Is a Water-Based Degreaser Concentrate? Uses, Benefits, and Top Applications

Introduction

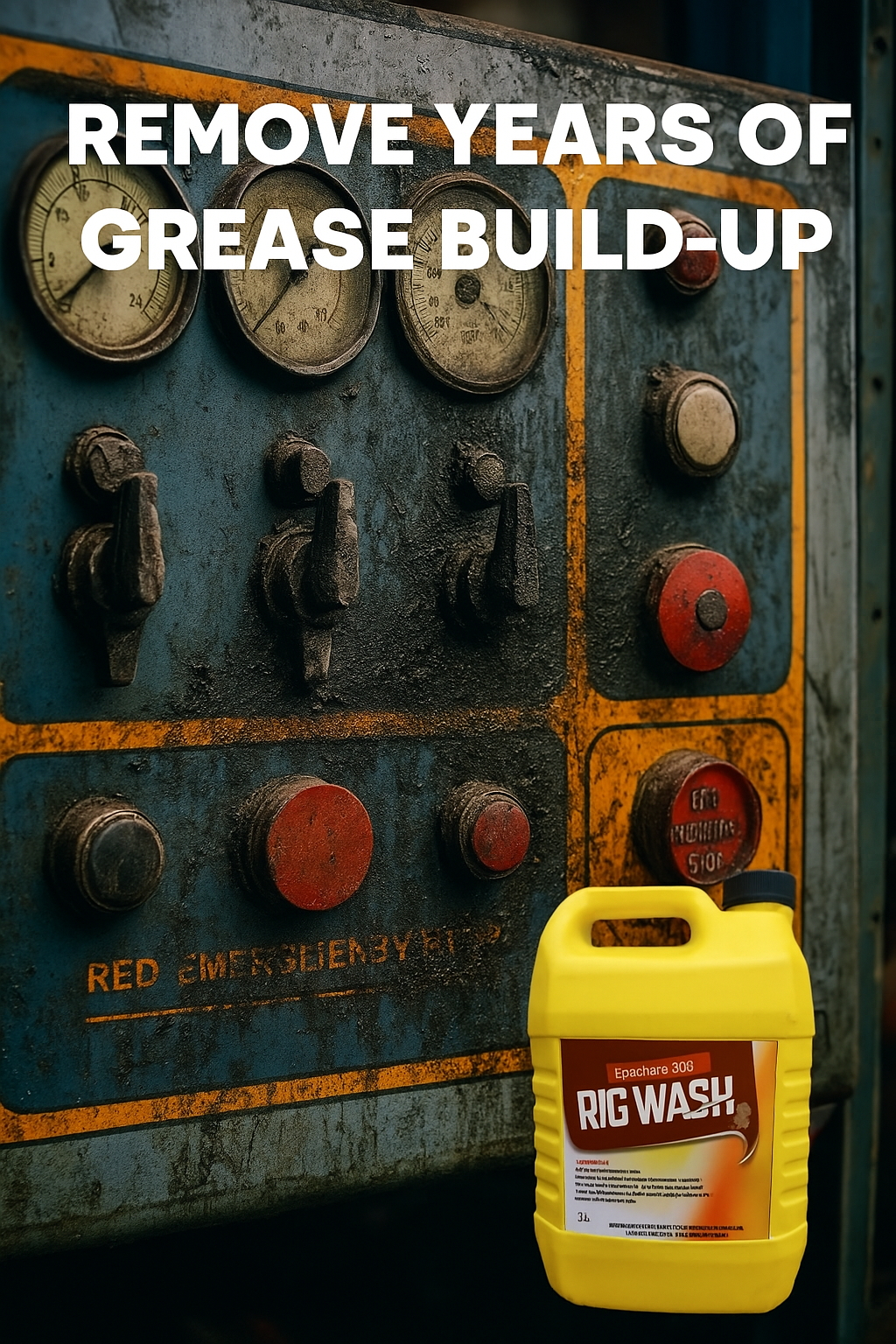

In industrial environments, whether oil rigs, heavy machinery workshops, or food processing plants, grease, oil, grime, and stubborn residues can severely impact operational efficiency and equipment lifespan. While solvent-based degreasers have long been used, growing concerns over safety, environmental impact, and fire hazards are steering industries toward safer, eco-friendly alternatives.

Enter water-based degreaser concentrates non-toxic, biodegradable, and just as powerful. One standout solution is Epochem 505 Rig Wash Degreaser, a non-chlorinated, non-corrosive, and water-soluble industrial-grade degreaser distributed by Epoxy Oilserv Nigeria Ltd.

Read more...What is the best Industrial cleaner? Water-based cleaners or solvent cleaners?

Key Takeaway

- Effective Yet Eco-Friendly Cleaning: Water-based degreaser concentrates provide powerful degreasing performance without harsh chemicals, making them safer for users and the environment.

- Versatile Applications: Suitable for a wide range of cleaning tasks, including industrial equipment, automotive parts, floors, walls, and food processing areas.

- Highly Concentrated & Economical: Can be diluted to different strengths depending on the application, offering cost savings and flexibility for various cleaning needs.

What Is a Water-Based Degreaser Concentrate?

A water-based degreaser concentrate is a high-performance cleaning solution formulated with surfactants, emulsifiers, and alkaline agents that are dissolved in water. Unlike solvent-based products, it contains no volatile or flammable hydrocarbons, making it non-toxic, non-flammable, and biodegradable.

Composition of Epochem 505

According to the Technical Data Sheet (TDS) and MSDS, Epochem 505 contains:

- Diethylene Glycol Mono Butyl Ether (CAS 112-34-5) – an effective grease-penetrating agent

- Dodecylbenzene Sulphonic Acid – a powerful surfactant

- Linear Alcohol Ethoxylate (C9–C11) – breaks down and lifts greasy contaminants

- Sodium Metasilicate – a strong alkaline cleaning agent and corrosion inhibitor

These ingredients are blended into a stable, water-soluble formula with a pH of 12.0–13.0, making it highly effective for degreasing operations, yet safe for use on metals, rubber, plastic, and more.

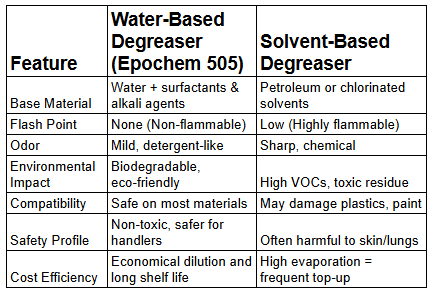

Water-Based vs. Solvent-Based Degreasers

Takeaway: Epochem 505 is an ideal substitute for solvent degreasers in industrial and marine cleaning due to its non-flammable nature, ease of use, and surface compatibility.

How Water-Based Degreasers Work

Water-based degreasers operate on a simple but effective principle: emulsification and suspension. Here's how it works:

- Surfactants lower surface tension, allowing the solution to penetrate oily residues.

- Emulsifiers break up the oil into microscopic droplets, suspending them in the water phase.

- Alkaline agents like sodium metasilicate saponify greasy deposits and neutralize acidic residues.

- Corrosion inhibitors form a thin film on metal surfaces to protect against rusting during and after cleaning.

The Epochem 505 Degreaser, when diluted or used full-strength, breaks down oils and grime even on complex surfaces like rig struts, pipelines, engines, and workshop floors.

Key Applications Across Industries

Epochem 505 Degreaser is exceptionally versatile. According to its TDS and application guidelines, it can be used in the following:

Oil & Gas / Marine Industry

- Rig floors, platforms, valves, compressors, and pumps

- Excellent resistance to salt and brine residues

- Removes grease spills and drilling fluids from offshore equipment

Manufacturing & Industrial Maintenance

- Cleaning sheet metals before painting

- Degreasing engines, gearboxes, bearings, spindles, and auto components

- Machine maintenance and preparation for inspections

Commercial & Institutional Facilities

- Pressure washing of walls, floors, and restrooms

- Safe for use on concrete, rubber, vinyl, and metal surfaces

- Removal of waxes, inks, and temporary coatings

Epochem 505 is available in bulk and industrial-size containers—making it suitable for large-scale operations and continuous-use environments.

Read more...Industrial Solvent Degreasers And Where They Are Needed

Benefits of Water-Based Degreaser Concentrates

Water-based degreasers are not just safer—they’re smarter. Their growing adoption across multiple industries is fueled by several distinct advantages, especially when using a product like Epochem 505:

Non-Flammable and Safe to Handle

Epochem 505 has a zero flash point, making it non-flammable—a major safety advantage in oil & gas, marine, and workshop environments where sparks or heat are present.

Eco-Friendly & Biodegradable

Free of chlorinated solvents and harsh chemicals, Epochem 505 is environmentally friendly, significantly reducing hazardous waste output and VOC emissions.

Heavy-Duty Cleaning Without Harshness

The high-alkaline pH (12.0–13.0) and potent surfactant blend allow it to cut through grease, oil, and wax—yet it remains safe for use on aluminum, stainless steel, rubber, and painted surfaces.

Corrosion Protection

Sodium Metasilicate acts as a built-in corrosion inhibitor, providing temporary rust protection after cleaning—a critical feature for offshore platforms and steel pipelines.

No Residue Left Behind

Unlike some degreasers that leave films requiring re-cleaning, Epochem 505 is low-foaming and rinses clean, which streamlines operations and improves results.

Cost-Effective Use

The product can be diluted for general use or used full-strength on tough grime. This flexibility helps stretch product life and reduce procurement costs.

Choosing the Right Water-Based Degreaser for Your Application

Different cleaning jobs require different formulations. Here are the most important factors to consider:

Type of Contaminant

- Light dirt or dust? A diluted solution is fine.

- Heavy grease or engine oil? Use Epochem 505 at full strength for best results.

Surface Type

Always check if your degreaser is safe for delicate materials. Epochem 505 is proven safe on:

- Metals: carbon steel, stainless steel, galvanized surfaces, copper, aluminum

- Non-metals: rubber, plastic, vinyl, and concrete

Required Cleaning Method

- For immersive cleaning, use Epochem 505 in soaking tanks or trays.

- For manual applications, apply with a mop or sprayer.

- For automated systems or pressure washing, dilute based on surface and grime levels.

Regulatory and Industry Compliance

Different industries—especially food processing, pharmaceuticals, and marine operations—require degreasers that meet specific safety and environmental standards.

- Food Industry: Ensure the product is non-toxic, non-residual, and compliant with local food safety standards. Epochem 505 is suitable for cleaning non-food contact surfaces such as floors and equipment exteriors.

- Oil & Gas / Marine: Look for degreasers that offer salt and brine resistance, and are safe to use around sensitive metal surfaces like stainless steel and aluminum—Epochem 505 is formulated with corrosion inhibitors to meet this need.

- Manufacturing / Engineering: Epochem 505’s compatibility with automated systems and safe pH range make it suitable for pre-treatment before painting, welding, or coating.

Environmental Impact & Disposal Requirements

While many solvent-based degreasers pose serious challenges in terms of waste disposal, Epochem 505 is biodegradable and water-soluble, reducing the environmental footprint of your operations.

- Diluted rinse water can often be discharged into conventional wastewater systems (check local regulations).

- Used products and containers must be disposed of according to local environmental guidelines—Epochem 505’s MSDS confirms that it does not contain DOT-classified hazardous materials, simplifying disposal logistics.

Worker Safety & Training

Always consider how easy the product is to handle and whether your team will require special PPE or ventilation:

- Epochem 505 is non-flammable, emits no harsh fumes, and only requires basic PPE like gloves and goggles during handling.

- Its low irritation profile (mild skin and eye irritant only with direct contact) means it is far safer than harsh solvent-based cleaners.

Best Practices for Usage and Storage

To get the most from your water-based degreaser concentrate like Epochem 505, follow these recommended practices:

Application Tips

Dilution Ratios:

- Light cleaning: 1 part Epochem 505 to 10 parts water

- Medium-duty: 1:5

- Heavy-duty or degreasing: Use full strength

Method of Application:

- Apply using a brush, sponge, mop, sprayer, or pressure washer

- Allow dwell time of 5–10 minutes before rinsing

- Agitate with a brush for heavily soiled surfaces

- Rinse thoroughly with clean water

Storage Guidelines

- Keep in tightly sealed containers

- Store in a cool, dry place away from acids and oxidizers

- Shelf life: up to 24 months in proper conditions

- Do not mix with acidic cleaners or other chemical agents

Safety Precautions

- Wear rubber gloves and safety goggles for prolonged exposure

- Avoid ingestion or prolonged skin contact

- In case of eye contact: flush with plenty of water and seek medical attention

- Keep out of reach of children

- Dispose of waste according to local environmental regulations

Frequently Asked Questions

1. Can I use Epochem 505 on aluminum or painted surfaces?

Yes, Epochem 505 is designed to be safe on most metals and coated surfaces, including aluminum and painted machinery.

2. Does this product require rinsing after use?

Yes. For best results and to avoid residue buildup, always rinse thoroughly with water after cleaning.

3. Is it safe for use in food processing areas?

While it is non-toxic and non-chlorinated, ensure the degreaser used is food-contact approved for such environments. Epochem 505 is suitable for cleaning floors and non-contact surfaces.

4. Can it be used in automatic parts washers or immersion tanks?

Absolutely. Epochem 505 is compatible with automated cleaning systems and immersion methods due to its non-foaming and water-soluble nature.

5. What surfaces are protected?

The degreaser is effective on carbon steel, stainless steel, galvanized surfaces, copper, plastics, rubber, and concrete.

Related Articles

Epochem 502 Citrus Degreaser earns recertification for continued use in the oil and Gas Sector

Benefits Of Using Industrial Cleaner And Degreaser

Conclusion

Water-based degreaser concentrates offer a powerful, versatile, and environmentally friendly solution for tackling tough grease and grime across various industries. By choosing these safer, non-toxic alternatives, you not only protect your equipment and surfaces but also create a healthier workspace and support sustainability goals.

Whether you're maintaining industrial machinery, cleaning automotive parts, or keeping food processing areas spotless, a high-quality water-based degreaser can make all the difference in efficiency and safety.

Ready to upgrade your cleaning routine with an effective, eco-friendly degreaser? Explore our range of premium water-based degreaser concentrates at GZ Industrial Supplies today. Our experts are here to help you find the right solution for your needs — keep your operations clean, safe, and compliant!