Epoxy Floor Coating For Aircraft Hangar

Introduction

In an aircraft hangar, the floor is more than just a surface, it's a critical operational asset. It supports the weight of multi-ton aircraft, endures chemical spills from aviation fluids, and contributes to the safety of ground crews and maintenance personnel. A poorly maintained or inadequate floor coating can result in hazards, costly downtime, or damage to sensitive aviation equipment.

That’s where epoxy floor coatings come in. Engineered for high performance, epoxy coatings provide the chemical resistance, load-bearing capacity, and seamless durability demanded in aviation environments. This guide explores why epoxy coatings are ideal for hangars, how they perform under the unique challenges of aviation operations, and how to select the right system for your facility.

Read more...Epoxy Floor Coating for Food and Beverage Industry

Epoxy Catalyst, Epochem 205, 20kg keg

Epoxy Catalyst, Epochem 205, 20kg keg

Key Takeaways

- Exceptional Durability: Epoxy floor coatings provide a tough, long-lasting surface that withstands heavy aircraft loads, rolling equipment, and frequent foot traffic without cracking or peeling.

- Chemical and Stain Resistance: These coatings are highly resistant to aviation fuel, hydraulic fluids, oils, solvents, and other harsh chemicals commonly found in hangar environments, helping maintain a clean and professional look.

- Enhanced Safety and Brightness: The glossy, light-reflective finish of epoxy floors improves visibility inside hangars and allows for the addition of slip-resistant textures and safety markings, promoting a safer workspace.

- Easy Maintenance and Cleaning: Smooth, seamless epoxy surfaces make cleaning oil drips, debris, and dirt quick and hassle-free, reducing downtime and maintenance costs.

Unique Flooring Challenges in Aircraft Hangars

Aircraft hangars are some of the most demanding environments when it comes to flooring performance. The combination of heavy equipment, high movement, and exposure to corrosive substances creates unique challenges that only specialized coatings like epoxy can meet effectively.

Exposure to Harsh Chemicals

Hangar floors regularly come into contact with:

-

Aviation fuel

-

Hydraulic fluids (e.g., Skydrol, which is highly corrosive)

-

Lubricants and engine oils

-

Solvents and degreasers

Standard concrete surfaces can absorb these liquids, stain, and degrade over time. Epoxy coatings create a non-porous, chemical-resistant barrier that prevents seepage and deterioration.

Heavy Loads and Abrasion

Whether it’s a fighter jet, a business aircraft, or a regional airliner, hangar floors must support the static and rolling loads of aircraft as well as tugs, lifts, carts, and maintenance machinery. Epoxy floors are designed to:

-

Resist abrasion from aircraft tires and tooling

-

Withstand tons of rolling pressure without cracking or delaminating

-

Maintain surface integrity even with frequent movement of equipment

Safety and Operational Efficiency

Hangar floors must be:

-

Slip-resistant to prevent injuries

-

Easy to clean to reduce the risk of fire or chemical reactions

-

Highly reflective to improve visibility and reduce lighting costs

-

Marked clearly for zones, taxi lines, and equipment storage

Epoxy systems can be customized with anti-skid additives, reflective finishes, and line striping for improved operational control and safety.

Read more...Key Considerations When Choosing Epoxy Floor Coatings: Thickness, Finish, and Color Options

What Is Epoxy Floor Coating?

An epoxy floor coating is a two-part system consisting of:

-

Epoxy resin (part A)

-

Hardener or curing agent (part B)

When mixed, these components undergo a chemical reaction that transforms them into a rigid, highly durable plastic-like material. Once cured, the epoxy forms a seamless, impermeable layer that bonds tightly to concrete substrates.

Epoxy Resin Epochem 105, 1kg Keg

Epoxy Resin Epochem 105, 1kg Keg

Types of Epoxy Systems Used in Hangars

-

100% Solids Epoxy: Offers maximum thickness and performance with no VOC emissions; ideal for heavy-duty aviation settings.

-

Self-Leveling Epoxy: Ensures a flat, smooth finish—critical for aircraft wheel movement and drainage.

-

Epoxy Quartz Systems: Embedded with quartz aggregates for added strength and slip resistance.

-

ESD Epoxy Coatings: Designed to safely dissipate static electricity—important for avionics repair zones and sensitive electronics handling.

Read more...HOW TO WORK SAFELY WITH EPOXY COATINGS

Why Epoxy Is Ideal for Aircraft Hangars

Epoxy coatings offer multiple benefits specifically aligned with the needs of aviation maintenance and storage facilities:

Chemical Resistance

Epoxy stands up to Skydrol, jet fuel, solvents, and other aggressive substances without discoloring, blistering, or degrading. This extends the life of the floor and keeps it looking professional.

Load Tolerance

Epoxy coatings distribute weight evenly and can support aircraft loads exceeding 100,000 lbs. when properly applied over prepared concrete slabs.

Easy Maintenance

The non-porous surface resists stains and is easily cleaned with water or mild detergent. It reduces cleaning time and eliminates concrete dust, which is essential in clean aviation environments.

Light Reflectivity

High-gloss epoxy can increase ambient light by up to 300%, improving visibility for hangar crews and reducing electricity consumption.

Safety Underfoot

Slip-resistant textures can be integrated using aggregates or silica, enhancing safety for foot traffic and vehicle maneuvering.

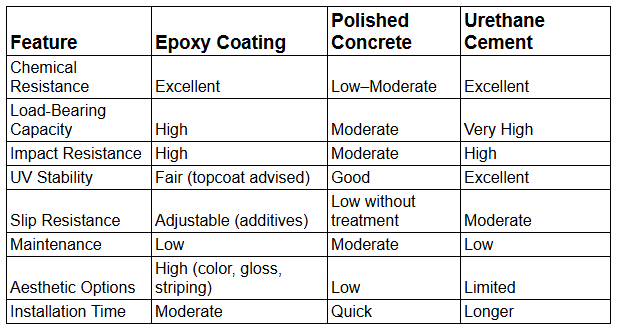

Comparison: Epoxy vs. Other Hangar Flooring Options

When choosing the best floor coating for your aircraft hangar, epoxy stands out—but it’s important to see how it compares to other commonly used flooring systems:

Read more...EPOXY FLOORING FOR HEALTH CARE SYSTEM

Installation Process of Epoxy in Aircraft Hangars

A properly installed epoxy system will offer years of performance. However, successful application requires strict adherence to preparation and installation guidelines:

Surface Preparation

-

Shot blasting or diamond grinding to remove contaminants, open pores, and create a bonding profile

-

Moisture testing to ensure no water vapor migration from the substrate

-

Repair of cracks and joints with epoxy fillers or flexible sealants

Priming

-

Apply a penetrating epoxy primer to enhance adhesion and seal the concrete surface

-

Important for preventing bubbles and ensuring a uniform finish

Application of Base & Build Coats

-

Apply the 100% solids epoxy build coat

-

Can be applied with rollers or squeegees depending on system design

-

Optional: Add quartz aggregate or silica sand for anti-skid or strength

Topcoat (Optional but Recommended)

-

For UV stability, chemical resistance, and gloss retention, apply a polyurethane or polyaspartic topcoat

-

This improves scratch resistance and maintains the high-gloss finish over time

Curing Time

-

Foot traffic: after 12–24 hours

-

Heavy equipment and aircraft: after 72–96 hours depending on temperature and humidity

-

Always follow manufacturer curing instructions for full performance

NovaTuff FC-200 Epoxy Floor Coating

NovaTuff FC-200 Epoxy Floor Coating

Maintenance and Longevity

One of epoxy’s greatest advantages is its low-maintenance nature and long lifespan, especially when installed and maintained correctly.

Routine Maintenance Includes:

-

Daily cleaning with microfiber dust mops or auto-scrubbers

-

Weekly wet washing using pH-neutral cleaners

-

Immediate cleanup of chemical spills to avoid surface softening or staining

-

Line striping touch-ups as needed

Periodic Maintenance:

-

Recoat every 5–7 years depending on traffic and chemical exposure

-

Re-polish or topcoat glossed surfaces for cosmetic renewal

-

Conduct quarterly inspections of joint edges, wear zones, and ESD grounding (if applicable)

Expected Lifespan:

-

With proper care, epoxy floors can last 10–15 years or more in aircraft hangars

-

Heavily used maintenance hangars may require earlier reapplication in work zones

-

Reflective and aesthetic qualities remain intact longer with regular topcoating

Cost Considerations

The cost of epoxy floor coating in an aircraft hangar depends on several variables, but the long-term ROI is often superior to other flooring options due to its durability and low maintenance.

Factors That Affect Cost:

-

Size of the hangar (costs scale with surface area)

-

Floor condition and prep level required (crack repair, moisture barriers, etc.)

-

Epoxy thickness and system complexity (e.g., basic seal vs. full-build coat with anti-skid quartz)

-

Additional features: ESD protection, topcoats, line striping, or logo customization

-

Labor and mobilization: especially in remote or restricted access locations

Average Price Range:

-

$6 – $12 per sq. meter for standard hangar-grade epoxy

-

$12 – $20+ per sq. meter for high-build, slip-resistant, or ESD systems

-

Keep in mind: epoxy reduces lighting costs, prevents damage to concrete, and lowers cleaning labor, delivering value over time.

Case Example: Military Hangar Epoxy Retrofit

Client: Nigerian Air Force Maintenance Hangar

Problem: Deteriorated concrete flooring with oil saturation, safety hazards, and poor light reflectivity

Solution:

-

Surface ground and sealed with vapor barrier primer

-

Installed 100% solids epoxy base, non-slip quartz additive

-

Marked service lanes and aircraft parking bays

Results: -

45% improvement in light reflectivity

-

Slip incidents reduced to zero in 12 months

-

Minimal maintenance required after one year of heavy-duty operations

Choosing the Right Epoxy System for Your Hangar

When selecting the best epoxy coating, consider:

-

Type of aircraft (light vs. heavy-duty jets)

-

Usage pattern (storage, maintenance, painting)

-

Chemical exposure (Skydrol, oils, solvents)

-

Climate and temperature (affects curing and performance)

-

Regulatory requirements (ESD, anti-slip, FAA/OSHA compliance)

Pro Tip: Always work with certified installers who specialize in aviation-grade epoxy systems and offer product warranties.

Frequently Asked Questions

1. How long does epoxy flooring last in a hangar?

With proper installation and care, 10–15 years or more.

2. Can epoxy withstand Skydrol and jet fuel?

Yes. High-grade epoxy like 100% solids systems are engineered for aviation-grade chemical resistance.

3. Does epoxy flooring reduce lighting costs?

Yes. Reflective coatings can increase ambient lighting by up to 300%, reducing reliance on overhead fixtures.

4. Can I install epoxy over old or cracked concrete?

Yes, with proper surface preparation and crack repair using epoxy patching compounds.

5. How long before I can drive or park an aircraft on a new epoxy floor?

Typically 72–96 hours after final application, depending on temperature and system thickness.

Related Article

Epoxy Floor Coating for Industrial Floors

EPOCHEM 304/404 Epoxy Floor Sealers

Where to Buy Epoxy Flooring Materials in Nigeria (2025 Guide)

Conclusion

In the demanding environment of an aircraft hangar, your floor is one of the most stressed surfaces in the facility. Epoxy floor coatings offer the ideal balance of performance, protection, and visual clarity, helping maintain safety, improve workflow, and reduce lifetime costs.

Whether you manage a private hangar, a commercial MRO facility, or a military aviation depot, epoxy delivers a durable, chemical-resistant, and easy-to-maintain solution that meets and exceeds aviation standards. By investing in high-quality epoxy flooring, you not only enhance operational efficiency but also protect your assets and create a professional, high-performance workspace.

Ready to upgrade your hangar with premium epoxy floor coatings? Explore top-quality epoxy solutions at GZ Industrial Supplies and transform your facility today