How Distilled Water Powers Up Your Inverter Battery

Key takeaway

Introduction

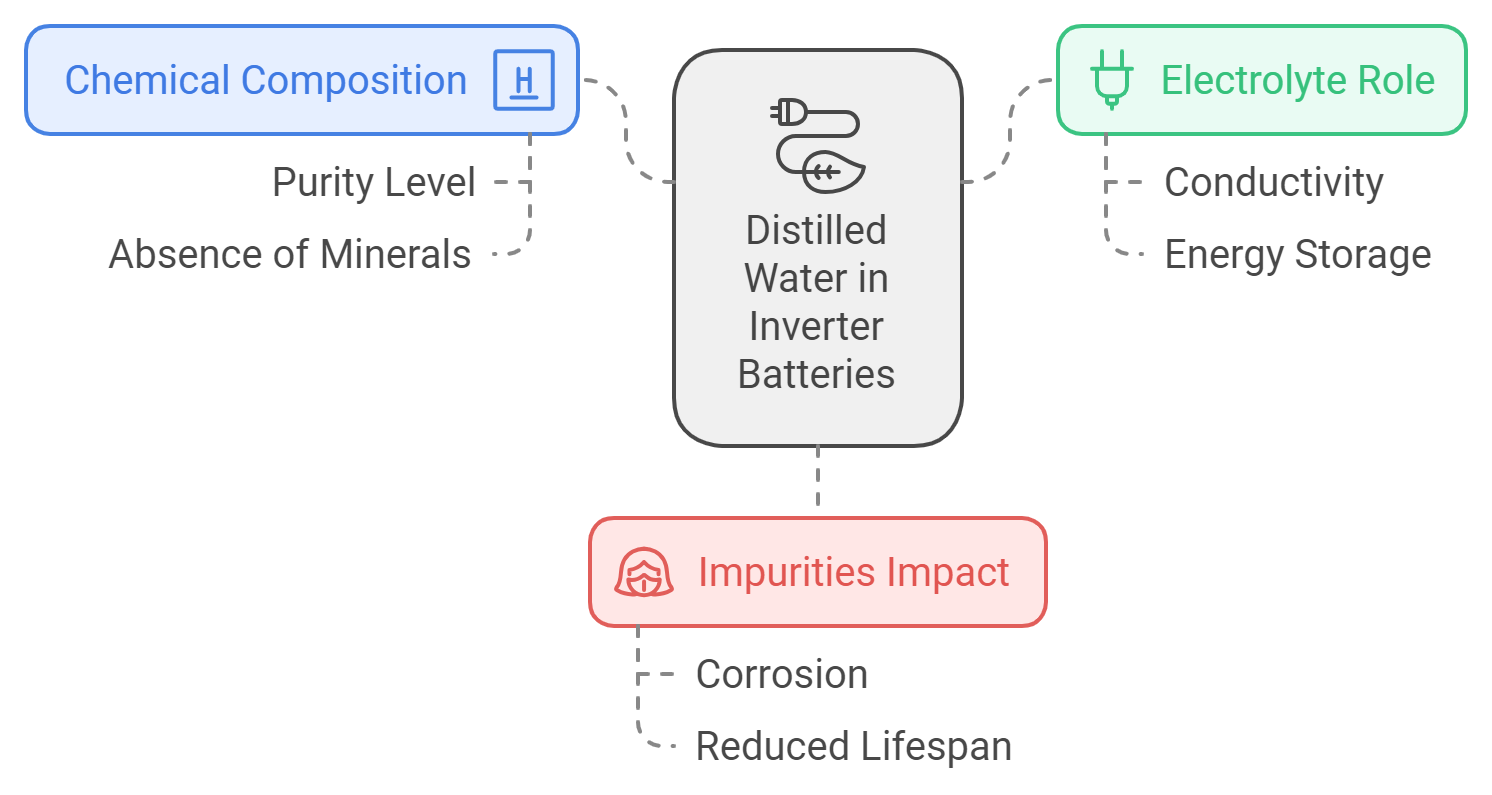

In recent time the use of distilled water for inverter battery maintenance have been the best choice, this is due to its exceptional purity and absence of impurities commonly found in regular tap water. In the intricate chemical processes occurring within an inverter battery, a solution of water and sulfuric acid, known as electrolyte, plays a vital role.

Epochem Distilled Water 20 Liters

The use of distilled water in inverter battery is critical for several reasons. Firstly, distilled water lacks the minerals, salts, and impurities present in regular water, minimizing the risk of sediment and scale buildup on the battery plates. This buildup, known as sulfation, has the potential to decrease the battery's capacity and overall lifespan. Secondly, the precise control over the concentration of sulfuric acid in the electrolyte, achievable with distilled water, ensures optimal chemical reactions, thus maximizing energy conversion efficiency. Moreover, distilled water aids in preventing corrosion and extends the life of the battery by reducing the chances of internal damage. Lastly, using distilled water helps maintain a stable temperature during the charging and discharging processes, preventing excessive heat that could otherwise damage the battery. In summary, the use of distilled water in inverter batteries is a key maintenance practice, contributing to the purity of the electrolyte, preventing mineral buildup, optimizing chemical reactions, and ultimately ensuring a longer and more reliable battery life. Regular checks and top-ups with distilled water are essential steps in the proper care and maintenance of inverter batteries.

In this exploration, we will understand the science behind distilled water in inverter batteries, understand its transformative role in mitigating common battery issues, and provide practical insights into its correct usage. Join us on a journey to discover how this seemingly basic substance, distilled water, becomes a powerful ally in extending the lifespan and reliability of your inverter battery.

The Science Behind Distilled Water

Distilled water is water that has been purified by boiling it into vapor and then condensing it back into liquid in a separate container. This process removes any impurities, such as minerals, ions, bacteria, and other contaminants, that may be present in the original water source. Distilled water is often used in laboratories, medical applications, and industrial processes that require high-purity water.

This is why it is preferred over regular water, such as tap water or rainwater, for inverter batteries because it contains dissolved salts, metals, and other substances that can affect the performance and lifespan of the battery. These substances can cause corrosion, electrolysis, sulfation, and short-circuiting of the battery plates and terminals, reducing the battery’s capacity and efficiency.

Distilled water, on the other hand, is a pure and efficient conductor of electricity because it has no dissolved solids or gases that can interfere with the flow of electrons. Distilled water also helps maintain the optimal pH and specific gravity of the electrolyte solution in the battery, which is essential for the chemical reactions that generate electricity. Distilled water also prevents the formation of crystals and deposits on the battery plates and terminals, which can reduce the contact area and increase the internal resistance of the battery.

The Connection Between Distilled Water and Battery Life

As we have seen, regular water contains impurities that can harm the battery’s performance. Impurities such as salts, metals, and acids can react with the battery’s electrolyte solution, which is a mixture of water and sulfuric acid, and cause it to lose its acidity and conductivity. This can reduce the battery’s ability to store and deliver electricity. Impurities can also create unwanted chemical reactions that produce heat, gas, and corrosion, which can damage the battery’s internal components and cause it to overheat, leak, or explode.

Preventing mineral buildup with distilled water

One of the main benefits of using distilled water for inverter batteries is that it prevents mineral buildup on the battery plates and terminals. Mineral buildup, also known as sulfation, is a common cause of battery failure. It occurs when the sulfur in the electrolyte solution combines with the lead in the battery plates and forms lead sulfate crystals. These crystals can coat the plates and terminals and reduce the contact area and the flow of electricity. They can also increase the internal resistance and the self-discharge rate of the battery, which means the battery will lose its charge faster and require more frequent recharging. Distilled water, being pure and free of minerals, does not contribute to sulfation and helps keep the battery plates and terminals clean and efficient.

Extending the lifespan of inverter batteries through proper water maintenance

Another advantage of using distilled water for inverter batteries is that it extends the lifespan of the battery. A typical inverter battery can last for about 3 to 5 years, depending on the usage and maintenance. However, using regular water can shorten the battery’s life by causing corrosion, electrolysis, sulfation, and other problems. Using distilled water can prevent these problems and help the battery last longer. However, distilled water is not a magic solution that can fix a damaged or old battery. It is important to follow proper water maintenance procedures to ensure the optimal performance and longevity of the battery. These procedures include checking the water level regularly, adding distilled water when needed, avoiding overfilling or underfilling the battery, and keeping the battery clean and dry.

Kan 12v. 220AH Solar Tubular Battery

Step-by-Step Guide to Adding Distilled Water

One of the most important aspects of water maintenance for inverter batteries is checking the water levels regularly. The water level in the battery determines the amount of electrolyte solution available for the chemical reactions that produce electricity. If the water level is too low, the battery may not have enough electrolyte to function properly and may suffer from sulfation, overheating, or dry charging. If the water level is too high, the battery may spill or leak the electrolyte, which can cause corrosion, short-circuiting, or fire hazards. Therefore, it is essential to check the water level in the battery at least once a month and keep it within the recommended range.

How to safely add distilled water to inverter batteries

Adding distilled water to inverter batteries is a simple but delicate process that requires some precautions and safety measures. Here are the steps to follow:

- Turn off the inverter and disconnect the battery from the power source. This will prevent any electric shocks or sparks that could damage the battery or cause injuries.

- Wear protective gloves, goggles, and clothing. The electrolyte solution in the battery is acidic and corrosive and can cause burns, irritation, or blindness if it comes in contact with the skin, eyes, or clothes.

- Remove the battery caps or vents. These are the small openings on the top of the battery that allow the gas to escape. You may need a screwdriver or a wrench to open them. Be careful not to damage or lose the caps or vents.

- Check the water level in each cell of the battery. You can use a flashlight or a hydrometer to see the water level inside the battery. The water level should be above the plates but below the maximum mark. If the water level is below the plates, the battery may be damaged and need to be replaced.

- Add distilled water to each cell of the battery. Use a funnel or a syringe to pour the distilled water slowly and carefully into the cells. Do not overfill or underfill the cells. The water level should be between the minimum and maximum marks. Do not use regular water, as it can cause mineral buildup and reduce the battery’s performance.

- Replace the battery caps or vents. Make sure they are tight and secure. Do not force or cross-thread them.

- Reconnect the battery to the power source and turn on the inverter. Check the voltage and current of the battery and make sure they are within the normal range.

Frequency and timing of water maintenance

The frequency and timing of water maintenance for inverter batteries depend on several factors, such as the type, size, age, and usage of the battery, the temperature and humidity of the environment, and the quality of the power supply. However, as a general rule, it is advisable to check the water level in the battery at least once a month and add distilled water when needed.

Some of the best times to add distilled water to inverter batteries are:

- Before charging the battery. This will ensure that the battery has enough electrolyte to store the charge and prevent sulfation.

- After discharging the battery. This will replenish the water that may have evaporated or consumed during the discharge and prevent dry charging.

- Before storing the battery. This will prevent the battery from losing its charge and becoming inactive during the storage period.

Benefits of Using Distilled Water for Inverter Battery

1. Ensuring optimal electrolyte levels for efficient battery operation

One of the main benefits of using distilled water for inverter batteries is that it ensures optimal electrolyte levels for efficient battery operation. The electrolyte solution in the battery is a mixture of water and sulfuric acid that enables the chemical reactions that produce electricity. The electrolyte level in the battery affects the battery’s capacity, voltage, and current. If the electrolyte level is too low, the battery may not have enough power to run the inverter and the appliances. If the electrolyte level is too high, the battery may spill or leak the acid, which can damage the battery and the inverter. Distilled water, being pure and free of impurities, helps maintain the optimal electrolyte level in the battery by preventing evaporation, consumption, and dilution of the acid. Distilled water also helps preserve the acidity and conductivity of the electrolyte, which are essential for the battery’s performance.

2. Minimizing the risk of sulfation and corrosion

Another benefit of using distilled water for inverter batteries is that it minimizes the risk of sulfation and corrosion. Sulfation and corrosion are two of the most common causes of battery failure. Sulfation occurs when the sulfur in the electrolyte combines with the lead in the battery plates and forms lead sulfate crystals. These crystals can coat the plates and terminals and reduce the contact area and the flow of electricity. Corrosion occurs when the acid in the electrolyte reacts with the metal parts of the battery and forms rust and deposits. These rust and deposits can damage the battery’s internal components and cause it to overheat, leak, or explode. Distilled water, being pure and free of minerals, metals, and acids, does not contribute to sulfation and corrosion and helps keep the battery plates and terminals clean and efficient. Distilled water also helps neutralize any excess acid that may accumulate in the battery and cause corrosion.

3. Improving overall inverter battery performance and reliability

A third benefit of using distilled water for inverter batteries is that it improves overall inverter battery performance and reliability. By ensuring optimal electrolyte levels and minimizing the risk of sulfation and corrosion, distilled water helps the battery deliver consistent and stable power to the inverter and the appliances. Distilled water also helps extend the lifespan of the battery by preventing premature aging and degradation of the battery. Distilled water also reduces the maintenance cost and frequency of the battery by avoiding the need for frequent replacement or repair of the battery. Distilled water also enhances the safety and security of the battery by preventing fire and explosion hazards that may result from using regular water.

Cleon Solar and Inverter Tall Tubular battery 12V 240AH

Distilled Water vs. Tap Water: A Comparative Analysis

A. Understanding the drawbacks of using tap water

Tap water, also known as municipal water or faucet water, is the water that comes from the public water supply system. Tap water is treated and regulated to meet certain standards of quality and safety for human consumption and domestic use. However, tap water is not suitable for inverter batteries because it contains various impurities that can affect the battery’s performance and lifespan. Some of the common impurities found in tap water are:

- Minerals: Tap water contains dissolved minerals, such as calcium, magnesium, iron, and sodium, that can form deposits and scales on the battery plates and terminals. These deposits and scales can reduce the contact area and the flow of electricity, increasing the internal resistance and the self-discharge rate of the battery. They can also cause electrolysis, which is the decomposition of water into hydrogen and oxygen gas, which can create bubbles and pressure inside the battery and reduce the electrolyte level.

- Metals: Tap water contains trace amounts of metals, such as copper, zinc, lead, and arsenic, that can react with the acid in the electrolyte and cause corrosion and oxidation of the battery components. Corrosion and oxidation can damage the battery’s internal structure and cause it to leak, overheat, or explode. They can also create unwanted chemical reactions that produce heat, gas, and corrosion, which can reduce the battery’s capacity and efficiency.

- Acids: Tap water contains organic and inorganic acids, such as carbonic acid, nitric acid, sulfuric acid, and chloric acid, that can lower the pH and the specific gravity of the electrolyte. The pH and the specific gravity of the electrolyte are important factors that determine the battery’s performance and longevity. If the pH and the specific gravity are too low, the battery may not have enough power to run the inverter and the appliances. If the pH and the specific gravity are too high, the battery may spill or leak the acid, which can damage the battery and the inverter.

B. Comparing the long-term effects on battery health

The long-term effects of using tap water on battery health are negative and detrimental. Using tap water can cause various problems, such as sulfation, corrosion, electrolysis, and dry charging, that can reduce the battery’s performance and lifespan. Some of the long-term effects of using tap water on battery health are:

- Sulfation: Sulfation is the formation of lead sulfate crystals on the battery plates and terminals due to the reaction of sulfur in the electrolyte and lead in the plates. Sulfation can reduce the battery’s capacity and efficiency by blocking the flow of electricity and increasing the internal resistance and the self-discharge rate of the battery. Sulfation can also cause the battery to lose its charge faster and require more frequent recharging. Sulfation can be reversed by using a desulfator or a charger, but it can also be prevented by using distilled water.

- Corrosion: Corrosion is the deterioration of the metal parts of the battery due to the reaction of acid in the electrolyte and metal in the components. Corrosion can damage the battery’s internal structure and cause it to leak, overheat, or explode. Corrosion can also create unwanted chemical reactions that produce heat, gas, and corrosion, which can reduce the battery’s capacity and efficiency. Corrosion can be prevented by using distilled water and by keeping the battery clean and dry.

- Electrolysis: Electrolysis is the decomposition of water into hydrogen and oxygen gas due to the passage of electric current through the water. Electrolysis can occur when the water contains dissolved minerals or metals that act as electrolytes. Electrolysis can reduce the electrolyte level and the acidity of the battery by consuming water and acid. Electrolysis can also create bubbles and pressure inside the battery that can cause it to spill or leak. Electrolysis can be prevented by using distilled water and by avoiding overcharging or undercharging the battery.

- Dry charging: Dry charging is the condition of the battery when it has insufficient water or electrolyte to function properly. Dry charging can occur when the water evaporates or is consumed due to electrolysis or sulfation. Dry charging can reduce the battery’s ability to store and deliver electricity and can cause sulfation, overheating, or dry charging. Dry charging can be prevented by using distilled water and by checking the water level regularly and adding distilled water when needed.

C. Making the case for distilled water as the superior choice

Based on the above analysis, it is clear that distilled water is the superior choice for inverter batteries. Distilled water is pure and free of impurities that can harm the battery’s performance and lifespan. Distilled water also helps maintain the optimal pH and specific gravity of the electrolyte, which are essential for the chemical reactions that generate electricity. Distilled water also prevents the formation of crystals and deposits on the battery plates and terminals, which can reduce the contact area and increase the internal resistance of the battery. Distilled water also reduces the maintenance cost and frequency of the battery by avoiding the need for frequent replacement or repair of the battery. Distilled water also enhances the safety and security of the battery by preventing fire and explosion hazards that may result from using tap water. Therefore, distilled water is the best choice for inverter batteries.

Tubular Battery 220AH/12V Invomax Genus

Common Mistakes and Misconceptions

Inverter battery water maintenance is a simple but important task that can affect the performance and lifespan of the battery. However, many people make some common errors in inverter battery water maintenance that can harm the battery and the inverter. Some of the common errors are:

1. Using regular water instead of distilled water:

As we have seen, regular water contains impurities that can cause sulfation, corrosion, electrolysis, and dry charging of the battery. These problems can reduce the battery’s capacity and efficiency and shorten its lifespan. Therefore, it is essential to use distilled water, which is pure and free of impurities, for inverter battery water maintenance.

2. Not checking the water level regularly:

The water level in the battery determines the amount of electrolyte solution available for the chemical reactions that produce electricity. If the water level is too low or too high, the battery may not function properly and may suffer from various problems. Therefore, it is important to check the water level in the battery at least once a month and keep it within the recommended range.

3. Adding too much or too little water:

Adding too much or too little water to the battery can also cause problems. If the water level is too high, the battery may spill or leak the electrolyte, which can damage the battery and the inverter. If the water level is too low, the battery may not have enough electrolyte to function properly and may suffer from sulfation, overheating, or dry charging. Therefore, it is advisable to add distilled water to the battery only when needed and keep the water level between the minimum and maximum marks.

4. Not following safety precautions:

Adding distilled water to inverter batteries is a simple but delicate process that requires some precautions and safety measures. Some of the safety precautions are: turning off the inverter and disconnecting the battery from the power source, wearing protective gloves, goggles, and clothing, removing the battery caps or vents carefully, using a funnel or a syringe to pour the distilled water slowly and carefully, replacing the battery caps or vents securely, and reconnecting the battery to the power source and turning on the inverter. Not following these safety precautions can result in electric shocks, sparks, burns, irritation, blindness, or injuries.

Dispelling myths surrounding the use of distilled water

Despite the benefits of using distilled water for inverter batteries, there are some myths surrounding the use of distilled water that may discourage or confuse some people. Some of the myths are:

Distilled water is expensive and hard to find:

Distilled water is not expensive or hard to find. Distilled water is available in most supermarkets, pharmacies, and online stores at reasonable prices. Distilled water can also be made at home by boiling water and collecting the vapor in a clean container. Distilled water is a worthwhile investment for inverter batteries, as it can save money and time in the long run by avoiding the need for frequent replacement or repair of the battery.

Distilled water is harmful to the environment:

Distilled water is not harmful to the environment. Distilled water is water that has been purified by removing any impurities, such as minerals, ions, bacteria, and other contaminants, that may be present in the original water source. Distilled water does not contain any chemicals or additives that can pollute the environment. Distilled water also does not contribute to water scarcity or wastage, as it can be reused and recycled. Distilled water is actually beneficial to the environment, as it helps prevent the emission of harmful gases and substances that may result from using regular water for inverter batteries.

Distilled water is not necessary for inverter batteries:

Distilled water is necessary for inverter batteries. Distilled water is the best choice for inverter batteries, as it helps maintain the optimal pH and specific gravity of the electrolyte, which are essential for the chemical reactions that generate electricity. Distilled water also prevents the formation of crystals and deposits on the battery plates and terminals, which can reduce the contact area and increase the internal resistance of the battery. Distilled water also reduces the maintenance cost and frequency of the battery by avoiding the need for frequent replacement or repair of the battery. Distilled water also enhances the safety and security of the battery by preventing fire and explosion hazards that may result from using regular water for inverter batteries.

Tips for avoiding pitfalls in water addition practices

To avoid pitfalls in water addition practices, it is important to follow some tips and best practices that can ensure the optimal performance and longevity of the battery. Some of the tips are:

Use a hydrometer to check the water level and the specific gravity of the electrolyte:

A hydrometer is a device that measures the density of a liquid. A hydrometer can help check the water level and the specific gravity of the electrolyte in the battery. The water level should be above the plates but below the maximum mark. The specific gravity of the electrolyte should be between 1.200 and 1.300. If the water level or the specific gravity is too low or too high, distilled water should be added or removed accordingly.

Use a voltmeter to check the voltage and current of the battery:

A voltmeter is a device that measures the electric potential difference between two points. A voltmeter can help check the voltage and current of the battery and make sure they are within the normal range. The voltage of the battery should be between 12 and 13 volts. The current of the battery should be between 10 and 20 amps. If the voltage or the current is too low or too high, the battery may need to be charged or discharged.

Use a desulfator or a charger to prevent or reverse sulfation:

A desulfator or a charger is a device that applies a high-frequency pulse or a high-current charge to the battery to break down the lead sulfate crystals and restore the battery’s capacity and efficiency. A desulfator or a charger can help prevent or reverse sulfation, which is a common cause of battery failure. Sulfation can be prevented by using distilled water and by avoiding overcharging or undercharging the battery. Sulfation can be reversed by using a desulfator or a charger, but it can also be irreversible if the battery is severely sulfated.

Lento Tubular Battery 220ah 12v

Troubleshooting and Signs of Water-related Issues

Recognizing symptoms of insufficient water levels

Insufficient water levels in the battery can cause various problems that can affect the performance and lifespan of the battery. Some of the symptoms of insufficient water levels are:

- Low voltage or current: If the water level in the battery is too low, the battery may not have enough electrolyte solution to store and deliver electricity. This can result in low voltage or current, which means the battery may not be able to power the inverter and the appliances properly. The battery may also lose its charge faster and require more frequent recharging.

- Sulfation: If the water level in the battery is too low, the battery may suffer from sulfation, which is the formation of lead sulfate crystals on the battery plates and terminals. Sulfation can reduce the battery’s capacity and efficiency by blocking the flow of electricity and increasing the internal resistance and the self-discharge rate of the battery. Sulfation can also cause the battery to lose its charge faster and require more frequent recharging.

- Overheating or dry charging: If the water level in the battery is too low, the battery may overheat or dry charge, which means the battery may operate without enough water or electrolyte to cool it down and prevent sulfation. Overheating or dry charging can damage the battery’s internal components and cause it to leak, overheat, or explode.

Identifying signs of mineral buildup or contamination

Mineral buildup or contamination in the battery can occur when the water used for the battery contains dissolved minerals, metals, or acids that can react with the battery’s electrolyte solution or components. Mineral buildup or contamination can cause various problems that can affect the performance and lifespan of the battery. Some of the signs of mineral buildup or contamination are:

- Deposits or scales: If the water used for the battery contains dissolved minerals, such as calcium, magnesium, iron, or sodium, they can form deposits or scales on the battery plates and terminals. These deposits or scales can reduce the contact area and the flow of electricity, increasing the internal resistance and the self-discharge rate of the battery. They can also cause electrolysis, which is the decomposition of water into hydrogen and oxygen gas, which can create bubbles and pressure inside the battery and reduce the electrolyte level.

- Corrosion or oxidation: If the water used for the battery contains trace amounts of metals, such as copper, zinc, lead, or arsenic, they can react with the acid in the electrolyte and cause corrosion or oxidation of the battery components. Corrosion or oxidation can damage the battery’s internal structure and cause it to leak, overheat, or explode. They can also create unwanted chemical reactions that produce heat, gas, and corrosion, which can reduce the battery’s capacity and efficiency.

- Low pH or specific gravity: If the water used for the battery contains organic or inorganic acids, such as carbonic acid, nitric acid, sulfuric acid, or chloric acid, they can lower the pH and the specific gravity of the electrolyte. The pH and the specific gravity of the electrolyte are important factors that determine the battery’s performance and longevity. If the pH and the specific gravity are too low, the battery may not have enough power to run the inverter and the appliances. If the pH and the specific gravity are too high, the battery may spill or leak the acid, which can damage the battery and the inverter.

Steps to rectify water-related issues and maintain optimal battery function

To rectify water-related issues and maintain optimal battery function, it is important to follow some steps and best practices that can ensure the optimal performance and longevity of the battery. Some of the steps are:

1. Use distilled water for inverter battery water maintenance:

Distilled water is the best choice for inverter battery water maintenance, as it is pure and free of impurities that can cause sulfation, corrosion, electrolysis, and dry charging of the battery. Distilled water also helps maintain the optimal pH and specific gravity of the electrolyte, which are essential for the chemical reactions that generate electricity. Distilled water also prevents the formation of crystals and deposits on the battery plates and terminals, which can reduce the contact area and increase the internal resistance of the battery. Distilled water also reduces the maintenance cost and frequency of the battery by avoiding the need for frequent replacement or repair of the battery. Distilled water also enhances the safety and security of the battery by preventing fire and explosion hazards that may result from using regular water for inverter batteries.

2. Check the water regularly and add distilled water when needed:

Checking the water level regularly and adding distilled water when needed is a simple but important task that can affect the performance and lifespan of the battery. The water level in the battery determines the amount of electrolyte solution available for the chemical reactions that produce electricity. If the water level is too low or too high, the battery may not function properly and may suffer from various problems. Therefore, it is important to check the water level in the battery at least once a month and keep it within the recommended range. Distilled water should be added to the battery only when needed and keep the water level between the minimum and maximum marks.

3. Follow safety precautions when adding distilled water to inverter batteries:

Adding distilled water to inverter batteries is a simple but delicate process that requires some precautions and safety measures. Some of the safety precautions are: turning off the inverter and disconnecting the battery from the power source, wearing protective gloves, goggles, and clothing, removing the battery caps or vents carefully, using a funnel or a syringe to pour the distilled water slowly and carefully, replacing the battery caps or vents securely, and reconnecting the battery to the power source and turning on the inverter. Not following these safety precautions can result in electric shocks, sparks, burns, irritation, blindness, or injuries.

Epochem Distilled Water 20 Liters

Related Articles:

Why Use Distilled Water For Inverter Battery

How To Store Inverter Battery When Not In Use

Conclusion

In this article, we have learned how distilled water powers up your inverter battery and why it is the best choice for inverter battery water maintenance. We have seen how distilled water helps maintain the optimal pH and specific gravity of the electrolyte, which are essential for the chemical reactions that generate electricity. We have also seen how distilled water prevents the formation of crystals and deposits on the battery plates and terminals, which can reduce the contact area and increase the internal resistance of the battery. We have also seen how distilled water reduces the maintenance cost and frequency of the battery by avoiding the need for frequent replacement or repair of the battery. We have also seen how distilled water enhances the safety and security of the battery by preventing fire and explosion hazards that may result from using regular water for inverter batteries.

Additionally, we have learned how to avoid common mistakes and misconceptions surrounding the use of distilled water and how to follow proper water maintenance procedures to ensure the optimal performance and longevity of the battery. We have learned how to check the water level regularly, how to safely add distilled water to the battery, how to use a hydrometer, a voltmeter, and a desulfator or a charger to monitor and improve the battery’s health, and how to recognize and rectify water-related issues.

We hope this article has been informative and helpful for you and that you will use distilled water for your inverter battery water maintenance. By using distilled water, you can empower your inverter battery for reliable performance and enjoy uninterrupted power supply for your home or office. Distilled water is the key to unlocking the full potential of your inverter battery and making it last longer and work better.

Contact us for more information