How to Install and Use Your Air Compressor for Optimal Performance

Introduction

Properly installing and using an air compressor is critical for ensuring safety, maximizing efficiency, and extending the lifespan of your equipment. Whether you’re setting up a small workshop or a large industrial facility, correct air compressor installation and operation are essential for powering pneumatic tools efficiently, maintaining workplace safety, and preventing unnecessary downtime.

In this guide, you'll learn key considerations for selecting the right installation location, essential steps for proper setup, and best practices for maintaining optimal air compressor performance.

Key Takeaways

-

Proper Installation is Crucial – Choose a well-ventilated area with a stable surface to prevent overheating and ensure efficient airflow.

-

Follow Manufacturer Guidelines – Always adhere to the installation and usage instructions provided by the manufacturer to maximize performance and safety.

-

Regular Maintenance Ensures Longevity – Routine checks, including draining moisture, inspecting filters, and lubricating moving parts, help prolong the compressor’s lifespan.

Preparing for Air Compressor Installation

Choosing the Ideal Location

Selecting the right location for your air compressor is crucial. An ideal spot will help your compressor operate effectively and safely over the long term. Consider the following factors:

Ventilation and Airflow:

Air compressors generate heat during operation, making ventilation essential. Ensure adequate airflow by placing your compressor in a well-ventilated area, away from walls or other equipment that could block airflow. Good ventilation prevents overheating, extends compressor life, and maintains optimal performance.

Accessibility for Maintenance:

Choose a location that allows easy access for routine maintenance tasks, such as oil changes, filter replacements, and moisture drainage. Having ample clearance around the compressor facilitates inspections and repairs, reducing downtime.

Stability and Vibration Control:

Position the compressor on a stable, flat surface to prevent vibrations and noise. Using anti-vibration pads or mounts can further reduce vibrations and noise levels, improving both safety and compressor durability.

Necessary Tools and Equipment for Installation

Before starting installation, ensure you have these essential items on hand:

-

Appropriate electrical wiring and outlets (check voltage requirements)

-

High-quality air hoses and fittings (to prevent leaks and maintain pressure)

-

Vibration isolation pads (to reduce noise and vibrations)

-

Air filters, moisture separators, and pressure regulators (for clean, dry air supply)

Preparing these items beforehand ensures a smooth and efficient installation process.

Read more...The Best Air Compressors for Industrial Use in Nigeria

Maxmech Air Compressor Da 1800-50

Step-by-Step Air Compressor Installation Guide

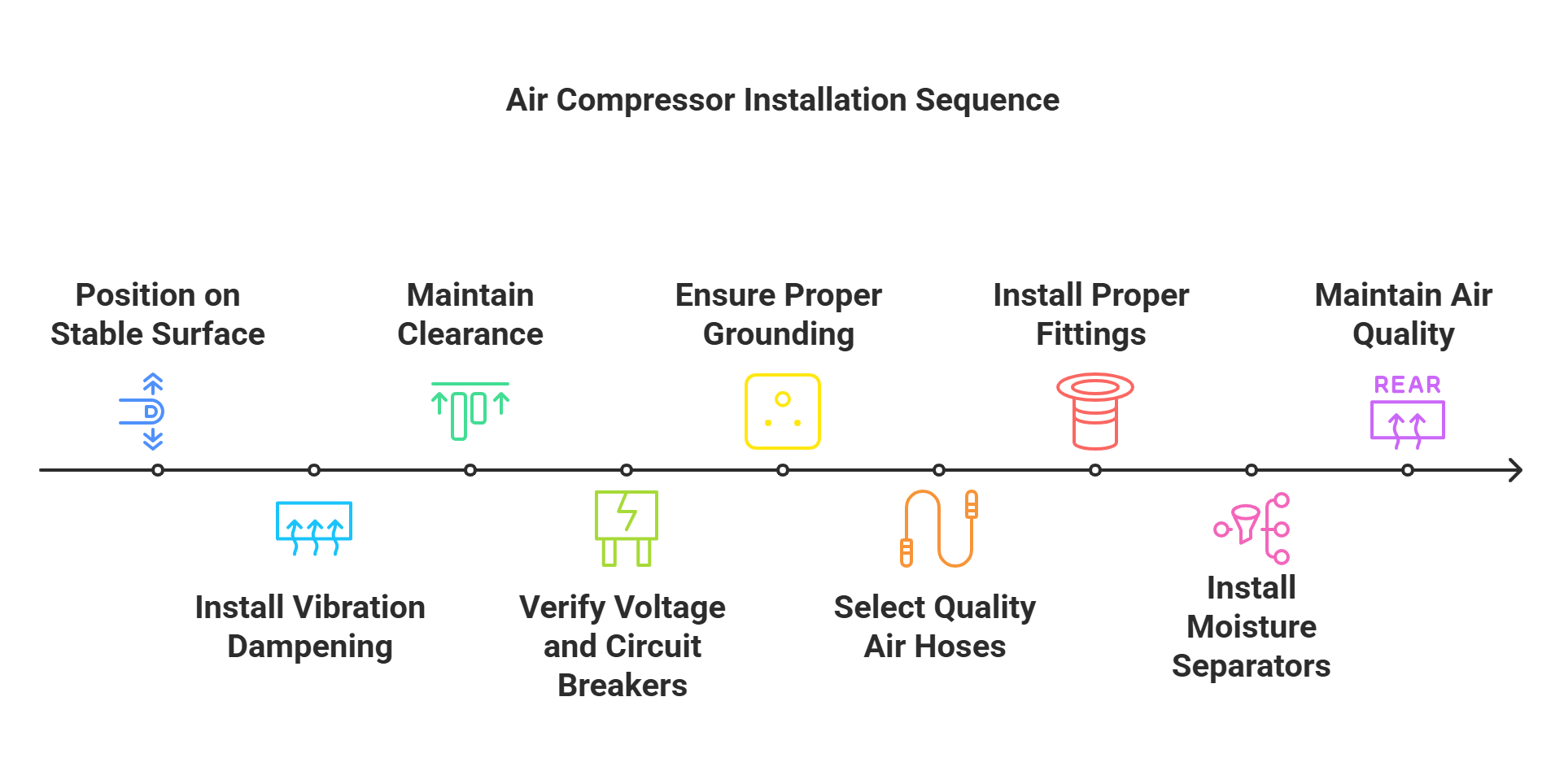

Positioning and Mounting the Compressor

Correct positioning is crucial to safe and efficient compressor operation. Follow these steps:

-

Stable and Level Surface: Position the compressor on a flat, stable surface to minimize vibrations and avoid tipping or falling during operation.

-

Vibration Dampening: Install vibration-reducing pads or mounts beneath the compressor legs. This reduces noise, extends compressor life, and protects surrounding equipment from vibration-related damage.

-

Clearance: Maintain at least 2-3 feet of clear space around all sides of the compressor to ensure adequate airflow and ease of maintenance access.

Electrical and Power Setup

A proper electrical setup ensures safety and protects your compressor:

-

Correct Voltage and Circuit Breakers: Verify the compressor's voltage requirements and ensure your electrical supply matches. Use dedicated circuits and suitable circuit breakers to avoid overload.

-

Proper Grounding: Ensure your air compressor is grounded correctly to prevent electrical hazards. Proper grounding reduces the risk of electrical shocks and damage to your equipment.

Air Connections and Hose Setup

Properly connecting air hoses and fittings is critical to maintaining air pressure and preventing leaks:

-

Select Quality Air Hoses: Use reinforced, high-pressure-rated hoses suited for industrial environments to minimize air leaks and withstand heavy usage.

-

Proper Fittings and Couplings: Install quick-release fittings for easy tool connection and disconnection, and ensure all fittings are tightly sealed and regularly inspected.

-

Install Moisture Separators and Filters: Include moisture separators or filters to remove water and debris, keeping air quality high and protecting your pneumatic tools from damage.

Installing Filters and Air Dryers

Contaminated air can severely affect tool efficiency and lifespan:

-

Air Filters: Regularly cleaned or replaced filters remove dirt and contaminants, keeping air quality optimal.

-

Air Dryers and Moisture Separators: Essential for humid climates, dryers and separators ensure moisture-free air, preventing corrosion inside your compressor and tools.

Best Practices for Optimal Compressor Usage

Ensuring proper usage practices maintains compressor efficiency and extends its operational life:

Operating at Recommended PSI and CFM

-

Match Tools and Compressor Output: Always operate your compressor at the recommended PSI and CFM ratings for your tools. Over-pressurization can damage tools, while insufficient airflow reduces efficiency.

-

Use Pressure Regulators: Pressure regulators ensure your pneumatic tools receive consistent, optimal pressure levels, reducing the risk of damage and improving performance.

Managing Compressor Duty Cycles

Understanding your compressor’s duty cycle (the percentage of time it can run before needing rest) is critical:

-

Follow Manufacturer Duty Cycle Guidelines: Operating beyond recommended duty cycles leads to overheating and potential compressor failure. Choose a compressor with a duty cycle that matches your workshop’s workflow.

-

Cooling and Ventilation: Improve ventilation and avoid prolonged continuous operation, ensuring adequate cooling periods to prevent overheating and extend your compressor’s lifespan.

Regular Leak Detection and Repair

Air leaks significantly reduce compressor efficiency and increase operational costs:

-

Routine Inspections: Regularly check your compressor system for leaks using methods like the soap-and-water test or ultrasonic leak detectors.

-

Prompt Repairs: Immediately repair any identified leaks to maintain optimal pressure and avoid unnecessary energy consumption.

Proper Ventilation and Temperature Control

Good airflow and temperature control are essential to compressor performance:

-

Ensure Adequate Airflow: Install your compressor in a ventilated location, away from heat sources or confined spaces.

-

Monitor Operating Temperature: Regularly check the compressor's temperature, and take immediate action if overheating occurs (e.g., pause operation, increase ventilation, or inspect cooling systems).

Maxmech Air Compressor 25L 600W

Frequently Asked Questions

1. How much clearance does my compressor need for proper ventilation?

Maintain at least 3 feet (about 1 meter) of clear space around your compressor for optimal airflow and ease of maintenance.

2. Can I use a regular extension cord to power my air compressor?

No, always use heavy-duty, dedicated wiring designed specifically for your compressor’s voltage and amperage requirements to avoid safety risks.

3. How often should I drain moisture from my compressor’s tank?

Ideally, moisture should be drained from the compressor tank daily, particularly in humid environments, to prevent rust and damage.

4. What PSI setting should I use for my pneumatic tools?

Most industrial pneumatic tools operate optimally at 90-120 PSI. Always check your tool manufacturer’s guidelines for precise settings.

5. Where can I purchase reliable air compressors and related accessories in Nigeria?

You can find a wide variety of high-quality industrial air compressors, hoses, filters, and accessories at GZ Industrial Supplies, your trusted welding and fabrication equipment supplier.

Related Articles

The Most Affordable Air Compressors in Nigeria for Industrial Applications

Air Compressor Maintenance Manual

The Role of Air Compressors in Industrial Fabrication Processes

Conclusion

Proper installation and usage of your air compressor are crucial for ensuring optimal performance, longevity, and efficiency in welding and fabrication tasks. By selecting the right location, following manufacturer guidelines, and performing regular maintenance, you can maximize your compressor’s lifespan while improving productivity. Safe handling practices and routine inspections help prevent costly breakdowns and ensure seamless operation in industrial applications.

For high-quality air compressors that deliver reliable performance, explore GZ Industrial Supplies today. Visit GZ Industrial Supplies to find the best air compressors and accessories tailored to your welding and fabrication needs!