Mastering Wood Routers: A Comprehensive Guide to Functionality and Performance

In the world of modern furniture-making, intricate designs, and exceptional craftsmanship are now more accessible than ever, thanks to the innovative technology of wood routers. Gone are the days of spending countless hours and resources on creating masterpieces by hand. With the advent of versatile and efficient tools like the Dongcheng wood router 900W 8MM DMR8, artisans can now produce cutouts, duplicate patterns, shape sharp edges, create joints, and add decorative surface cuts with ease and precision. Routing enhances the overall design of a workpiece, resulting in beautifully finished edges and corners.

Wood routers are powerful and indispensable tools for a wide range of woodworking tasks, from heavy-duty operations such as cutting and grinding to delicate trimming work. This article will provide a comprehensive overview of how wood routers, specifically the Dongcheng DMR8, operate, as well as discuss their advantages, essential features, and pricing options. Discover the world of possibilities that wood routers bring to the art of furniture making and elevate your woodworking projects to new heights.

What are Wood routers?

While using a router table or a handheld router, woodworkers can make cutouts, sharp edges, rounded edges, joints, decorative cuts, rabbets, and dadoes, and they can even make duplicates from a pattern. There are many router projects woodworkers can tackle with a standard cutting bit, but switching to one of several router bit shapes to create unique designs and intricate patterns can open up more customization options.

DongCheng Wood Router 900W 8MM DMR8

How Dongcheng Wood Router Works

A router works by spinning at speed to shape, cut and trim wood to create perfectly finished edges and corners. Routing a workpiece enhances its overall design.

They are most commonly used to create patterns in wood, such as round off worktop edges, add detailing to picture frames and cabinetry and so much more. By doing so, they take plain wooden edges to the next level.

But believe it or not, wood routers do more than just shape and cut wood. You can create dadoes, rabbets and more.

The Major Components of a Dongcheng Wood Router

A Dongcheng trimmer & router typically consists of several key components, including the motor, the collet, the base, the depth adjustment ring, the guide, and the cutting bit.

The motor is the heart of Dongcheng trimmers & routers, providing power to the cutting bit. The collet is the part of the tool that holds the cutting bit securely in place. The base is the flat surface that rests on the workpiece and supports the tool during operation. The depth adjustment ring allows you to adjust the height of the cutting bit, which determines how deep it cuts into the material. The guide helps keep it steady and ensures that the cuts are straight and accurate.

Instructions for operation for Dongcheng Wood Routers

-

Installing or Removing the Router bit

Insert the bit all the way into the collet cone. Press the spindle lock to keep the spindle stationary and use the wrench to tighten the collet nut securely.

When using router bits with smaller shank diameter, first insert the appropriate collet sleeve into the collet cone and then install the bit as described above. To remove the bit, follow the installation procedure in reverse.

CAUTION

- Always be sure that the tool is switched off and unplugged before installing or removing the router bit.

- Install the bit securely. Always use only the wrench provided with the tool. A loose or overtightened bit can be dangerous.

- Do not tighten the collet nut without inserting a bit or install small shank bits without using a collet sleeve. Either can lead to breakage of the collet cone.

2. Adjusting the Depth of cut

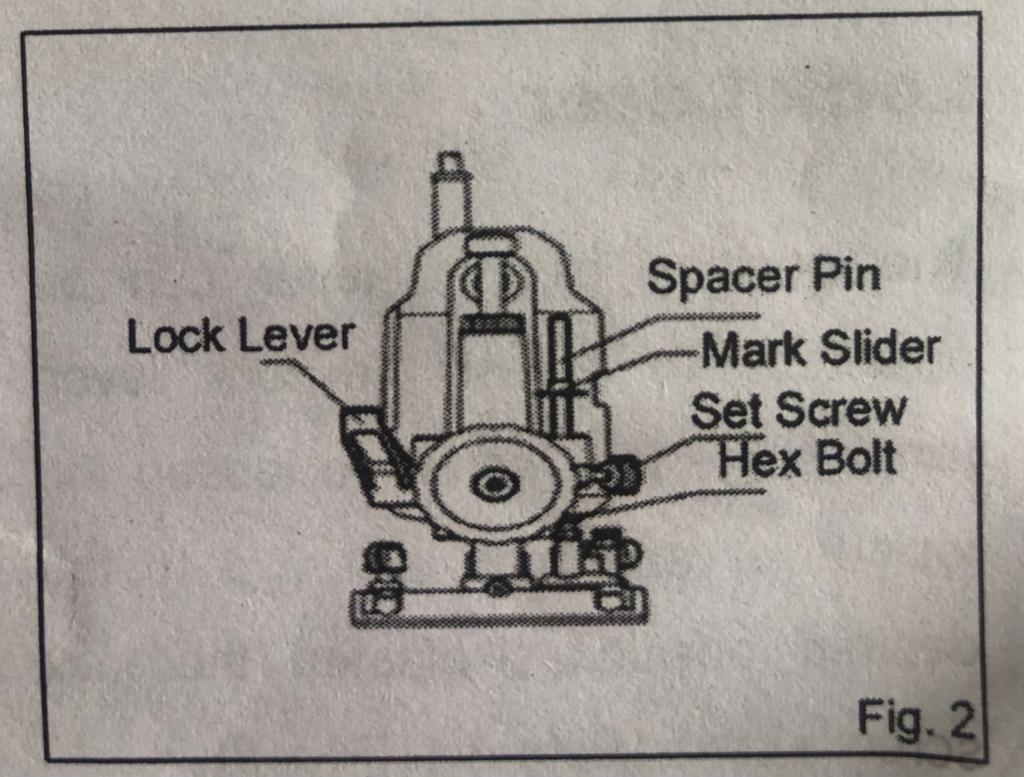

Place the tool on a flat surface. Loosen the lock lever and lower the tool body until the bit just touches the flat surface. Fasten the lock lever to lock the tool body. Loosen the set screw and lower the spacer pin until it touches the hex bolt. Align the mark slider with scale “0” on the ruler. Uplift the spacer pin to the desired position and tighten the set screw. Cutting depth is shown as the scale on the ruler with which the mark slider aligns (every scale means 1mm).

Desired depth of the cut can be obtained by loosening the lock lever and then lowering the tool body until the spacer pin makes contact with the adjusting hex bolt. The upper limit of the tool body can be adjusted by turning the plastic nut. Turn the plastic nut to lower the upper limit when the tip of the bit is retracted more than required in relation to the base plate surface.

CAUTION

Always be sure that the tool is switched off and unplugged before adjusting the depth of cut.

As excessive cutting may cause overload of the motor or difficulty in controlling the tool, so the depth of cut should not be more than 15mm (⅝”) at a pass when cutting grooves. For extra deep grooving operations ,make two or three passes with progressively deeper bit settings.

Do not lower the plastic nut too low; the bit will protrude dangerously.

3. Stopper

There are three hex bolts on the stopper. Cutting depth can be adjusted by just turning those bolts, which is much more convenient than the above process. The cutting depth increases or decreases 0.8mm by each turn.

4. Lock Lever

The position of the lock lever can be adjusted. To adjust the lock lever, remove the lock screw to loosen the lock lever and then adjust it to the desired position. Refasten the lock screw after adjustment.

5. Switch Action

To start the tool, press the switch trigger to the position “1”. To stop the tool , press the switch trigger to the position “0”.CAUTION

Hold the tool firmly when turning off the tool to overcome the kickback.

Understanding the Use of straight guides in Routers

When using the straight guide, be sure to install it on the right side of the feed direction. This will help to keep it flush with the side of the workpiece.

Place the tool on the workpiece to be cut without the bit making any contact. Then switch on the tool and wait until the bit attains full speed. lower the tool body and move the tool forward over the workpiece surface, keeping the tool base flush and advancing smoothly until the cutting is complete.

When doing edge cutting, the workpiece surface should be on the left side of the bit in the feed direction.

1 workpiece

2 rotational direction

3 view from the top

4 feed direction

The straight guide is effectively used for straight cuts when chamfering or grooving.

To install the straight guide, insert the guide holder into the holes in the tool base. Then adjust the distance between the bit and the straight guide. Secure the straight guide by tightening the wing bolt after adjusting the distance.

Move the tool only when the straight guide line up with the one side of the workpiece during operation

If the distance A between the side of the workpiece and the cutting position is too wide for the straight guide, or if the side of the workpiece is not straight, the straight guide cannot be used. In the case firmly clamp a straight board to the workpiece and use it as a guide against the trimmer base. Feed the tool in the direction of the arrow.

Understanding the Use of Templet guide in Routers

The Templet guide provides a sleeve through which the bit passes, allowing use of the router with templet patterns fig11.

To install the Templet guide, loosen the screws on the tool base, insert the Templet guide and then tighten the screws. Fig12.

Secure the templet to the workpiece. Place the tool on the and move the tool with the templet guide sliding along the side of the templet. fig 13.

Note:

The workpiece will be cut a slightly different size from the Templet allow for the distance x between the bit and the outside of the Templet guide fig 13.the distance x can be calculated by using the following equation:

Distance x outside diameter of the Templet guide- bit diameter / 2

Recommended DongCheng Routers

Dongcheng Wood Router 900W 8MM DMR8

The Dongcheng Wood Router DMR8 is an ideal tool for effortless and seamless craft work. It is widely used in the furniture and wood processing industries, this precision router is equipped with a powerful motor that makes it the best choice for milling. The balanced design of the tool ensures smooth and precise cuts, making it a top performer in the business.

The Dongcheng Wood Router 900W 8MM DMR8 is user-friendly and can be used by almost anyone, regardless of skill level. With a no-load speed of 27500 rpm, a collet diameter of 8mm and a power output of 900W, this router is quite powerful, delivering smooth routing consistently, making it a go-to tool for various industries. It weighs just about 2.95 kg, making it easy to transport and use overhead.

Specifications of DongCheng Wood Router 900W 8MM DMR8

Brand: Dongcheng

Collet Diameter: 8 mm

Model: DMR8

No-Load Speed: 27500 RPM

Power: 900W

Weight: 2.95 Kg

Maintenance and Inspection of Wood Routers

1. Inspecting and Replacing the Carbon Brushes

Remove and check the carbon brushes regularly. Replace when they wear down to the limit mark fig14. keep the carbon brushes clean and free to slip in the holders. Both carbon brushes should be replaced at the same time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take out the worn carbon brushes, insert the new ones and secure the brush holder caps.

Caution: always be sure that the tool is switched off and unplugged to perform inspection or maintenance.

Personal safety while using a wood Router

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication . A moment of inattention while operating power tools may result in serious personal injury.

1. Use personal protective equipment.

Always wear eye protection. Protective equipment such as dust masks, non-skid safety shoes, hard hats, or hearing protection used for appropriate conditions will reduce personnel injuries.

Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

2. Remove any adjusting key or wrench before turning the tool on.

A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

3. Do not overreach.

Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations

4. Dress properly.

Do not wear loose clothing or jewellery. Keep your hair ,clothing, and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities ensure these are connected and properly used . Use of dust collection can reduce dust related hazards.

About DongCheng

Jiangsu Dongcheng M&E Tools Co., Ltd., the Director of China Electric Tool Association, is one of the key backbone enterprises manufacturing professional power tools in China. With a high-class industrial production base, which covers 112,800㎡ while the building area is 58,000㎡, the company owns lots of advanced production equipment and testing apparatus and has a group of senior professional engineers and a team of intermediate and senior executives and technicians. Now the company employs more than 2700 staff totally. Dongcheng Company manufactures various types of power tools and their spare parts.

All the power tools produced by Dongcheng have passed the China Compulsory Certificate (CCC) authentication, if within the range of it. Dongcheng product is widely used in the fields of building construction and decoration, home decoration, stone industry, shipbuilding industry, water conservancy project, etc. The company has lots of distributors in all large and medium cities throughout China and also exports its products to South-East Asia, the Middle East, and South America, more than 30 countries & districts.

Dong Cheng company manufactures various types of power tools like Angle Grinder, Cordless Brushless Drill Driver/Hammer, Impact Drill, and related spare parts, which are widely used in the fields of building construction, home decoration, stone industry, shipbuilding, and water conservancy project.

Frequently Asked Questions

1. What's the difference between a trimmer and a router?

Routers are used for large-scale woodworking, while trimmers are for small jobs. Trimmers can work on a narrow base due to their compact size, while routers cannot. Trimmers can also make pin holes real quick, while routers cannot.

2. What is a wood router good for?

Trim routers have become an essential power tool in most workshops due to their versatility. They can be used for a wide range of tasks, such as routing for inlay cavities and hinge mortises, rounding over edges, flush trimming, hardwood edging, and much more.

3. Can a trimmer be used as a router?

Laminate trimmers have evolved to the point where they are essentially fully functional miniature routers. They are not only capable of trimming and flushing, but can also be used for jointing, rounding edges, chamfering, routing grooves and dados, dovetails, and even mortise and tenon joinery.

Conclusion

To sum up, Dongcheng wood routers are essential tools in many industries, providing creativity and reducing effort. This makes it crucial to have well-made tools, and that's where Dongcheng power tools come in. With their reliable and powerful performance, a Dongcheng wood router is an excellent choice for heavy-duty operations on wood and similar materials.

If you're in Nigeria, GZ Industrial Supplies is the place to go. As one of the major distributors and suppliers of Dongcheng Power Tools in the country, we offer a wide range of other high-quality industrial tools, as well as the Dongcheng trimmer router. With our reputation for providing excellent customer service and support, you can trust that purchasing your Dongcheng trimmer router from GZ Industrial Supplies is a smart investment. We have various locations in Lagos, Port harcourt, Abuja and Calabar, so you can visit us at your convenience or Contact us Here. Don't miss out on this opportunity to add a valuable tool to your toolkit - contact GZ Industrial Supplies today!