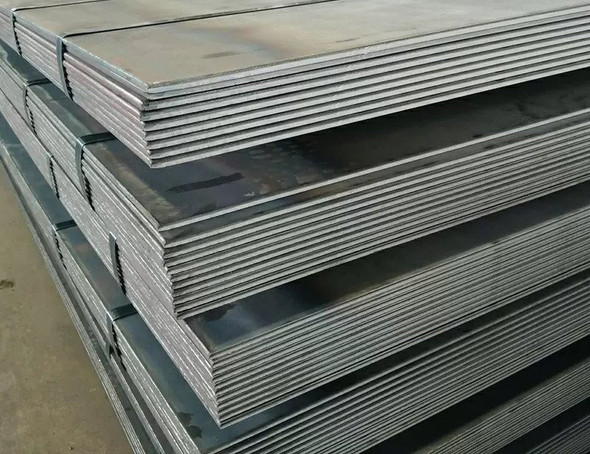

Structural Steel 6000x 1500x10mm Steel Plates

GZ Industrial Supplies is a distributor and supplier of Structural steel Materials in Nigeria. Our high-quality Structural Steel 6000x 1500x10mm Steel Plates, are manufactured to meet the highest standards of quality and performance, delivering exceptional strength and durability.

With a length of 6000mm, width of 1500mm, and thickness of 10mm, our Structural Steel Plates are versatile and suitable for a wide range of uses. Whether you need to construct buildings, bridges, railway stations, or fabricate pipeline components and industrial equipment, our steel plates have you covered.

The hot-rolled manufacturing technique ensures that our plates maintain excellent dimensional accuracy and structural integrity. They can be easily processed through bending, welding, decoiling, cutting, punching, and polishing, making them highly adaptable to your specific requirements.

These Structural Steel 6000x 1500x10mm Steel Plates are designed for durability and reliability. They are manufactured using industrial-grade structural steel, ensuring exceptional performance in demanding environments.

Structural Steel 6000x 1500x10mm Steel Plates Applications

-

Structures in Buildings, bridges, railway stations

-

Fabrication of pipeline components & Industrial equipment

-

Construction of automotive bodies, warehouses, shipping containers

-

Commercial appliances, etc.

Technical Specifications of Structural Steel 6000x 1500x10mm Steel Plates

-

Product Name: Structural Steel Plate

-

Length: 6000mm

-

Width: 1500mm

-

Thickness: 10mm

-

Manufacturing: Technique Hot rolled

-

Processing method: Bending, Welding, Decoiling, Cutting, Punching, Polishing

-

Thickness tolerance: ±0.1mm

-

Material: Industrial Grade Structural Steel

Frequently Asked Questions

1.What Type Of Welding Is Used For Structural Steel?

Stick welding and self-shielded flux-cored arc welding (FCAW-S) processes are most commonly used for structural steel applications in the field, while gas-shielded flux-cored arc welding (FCAW-G) and submerged arc welding (SAW) are used for indoor structural steel welding.

2.What Is The Best Wire For Welding Structural Steel?

An ER70S-6 solid wire is the most common choice for welding mild steel.

3.What Are The Benefits Of Using Structural Steel In Construction?

There are many benefits to using structural steel in construction. Steel is incredibly strong and durable, making it an ideal material for building structures that need to withstand heavy loads or harsh weather conditions. Additionally, steel is a versatile material that can be fabricated into a wide variety of shapes and sizes, allowing for greater flexibility and creativity in the design of a building. Structural steel is also easy to assemble and install, which can save time and money during the construction process.

Related Articles

Where to Buy Structural Steel Materials in Nigeria: Finding Reliable Suppliers

Understanding structural steel, its different forms, and their benefits

Structural Steel Material Selection: Factors to Consider for Different Applications

Contact us we have products available in all our stores nationwide.