Structural Steel Material Selection: Factors to Consider for Different Applications

When it comes to construction projects, selecting the right structural steel materials is of paramount importance. The chosen materials play a significant role in determining the structural integrity, durability, and overall performance of the built environment. Making informed decisions regarding material selection can lead to cost-effectiveness, sustainability, and successful project outcomes.

Structural Steel Materials are a widely used construction material known for its versatility, strength, and durability.It is primarily composed of iron and carbon, with small amounts of other elements such as manganese, silicon, and copper. The unique properties of Structural Steel, such as its high strength-to-weight ratio, ductility, and versatility in fabrication, make it a preferred choice in various construction applications. Some examples includes H-beams. I-beams, columns, steel piles etc.

Structural Steel finds extensive use in diverse projects, including high-rise buildings, bridges, industrial structures, residential and commercial buildings, and infrastructure projects. Its adaptability allows for innovative designs, efficient construction methods, and the ability to meet specific project requirements. This article will explore the factors to consider when selecting Structural Steel for different applications in construction.

In the following sections, we will delve into the key factors that need to be taken into account when selecting Structural Steel for different construction applications. By understanding these factors, construction professionals and stakeholders can make well-informed decisions that align with project goals and requirements. Through careful consideration of these factors, the appropriate Structural Steel material can be chosen to ensure optimal performance, durability, and cost-effectiveness in various construction projects.

Understanding Structural Steel

Structural Steel refers to a category of steel that is specifically designed and manufactured for use in construction and structural applications. It is a versatile material known for its exceptional strength, durability, and load-bearing capabilities. The use of Structural Steel in construction offers numerous advantages and has become a popular choice for a wide range of projects.

Structural Steel possesses several key characteristics that make it suitable for structural applications. Firstly, it has a high strength-to-weight ratio, which means that it can carry substantial loads while being relatively lightweight. This characteristic allows for the creation of structures with reduced material requirements and allows for more efficient and cost-effective designs.

Structural Steel also exhibits excellent ductility, which refers to its ability to deform under stress without fracturing. This ductility allows for the absorption of energy and redistribution of loads, making Structural Steel highly resistant to impact and dynamic forces. It enables structures to withstand seismic events, wind loads, and other external forces.

Additionally, Structural Steel has excellent uniformity and consistency in its properties, ensuring predictable and reliable performance. The material is manufactured to specific standards and undergoes rigorous quality control processes to meet the required mechanical properties and performance criteria.

Structural Steel 6000 x1500x16mm Steel Plates

Overview of the types and grades of Structural Steel

Structural Steel is available in various types and grades, each with its own unique properties and characteristics. The selection of the appropriate type and grade of Structural Steel depends on the specific project requirements, including the intended application, load-bearing capacity, and environmental conditions. Some common types and grades of Structural Steel include:

1. CARBON

a) Low Carbon Steel Grades/mild steel:

Low carbon steel has 0.04–0.3% carbon content and is the most common grade of carbon steel. Mild steel is also considered low carbon steel as it is defined as having a low carbon content of 0.05–0.25%. Mild steel is ductile, highly formable, and can be used for automobile body parts, plates, and wire products. At the higher end of the low carbon content range, and with the addition of manganese of up to 1.5%, mechanical properties are suitable for stampings, forgings, seamless tubes, and boiler plates. Let us look at some product profile of Low carbon steels commonly used for construction purposes in Nigeria.

2. Alloy steel Grade:

Alloy steel is a type of steel that contains alloying elements in addition to carbon, which helps enhance its mechanical properties such as strength, hardness, and wear resistance. There are numerous alloy steel grades available, each with its own unique composition and properties. Here is a list of some common alloy steel grades: ASTM A572 Grade 50, AISI 4140, AISI 4340, AISI 8620, ASTM A387 Grade 11, and ASTM A514 Grade B.

3. Tool steel:

Tool steel is a type of metal alloy that is used primarily in manufacturing tools. It is usually made from iron, carbon, and other elements such as chromium, molybdenum, or tungsten. It is often heat-treated to increase its durability and strength. This makes it an ideal material for making parts that must withstand high levels of force or friction without breaking or wearing down quickly. Tool steels are often used to make knives, punches, dies, cutting tools, drill bits, taps, reamers, saws, and hammers. Tool steel is a specialized type of alloy steel that is designed and manufactured specifically for use in the production of tools, dies, and cutting implements. It possesses excellent hardness, wear resistance, and toughness, making it suitable for applications that require high strength and durability.

4. Stainless steel Grade:

Stainless steel is a widely used metal alloy known for its exceptional corrosion resistance, durability, and versatility. It is composed primarily of iron, along with varying amounts of chromium, nickel, and other elements, depending on the specific grade. The selection of a stainless steel grade depends on the desired properties and the intended application.

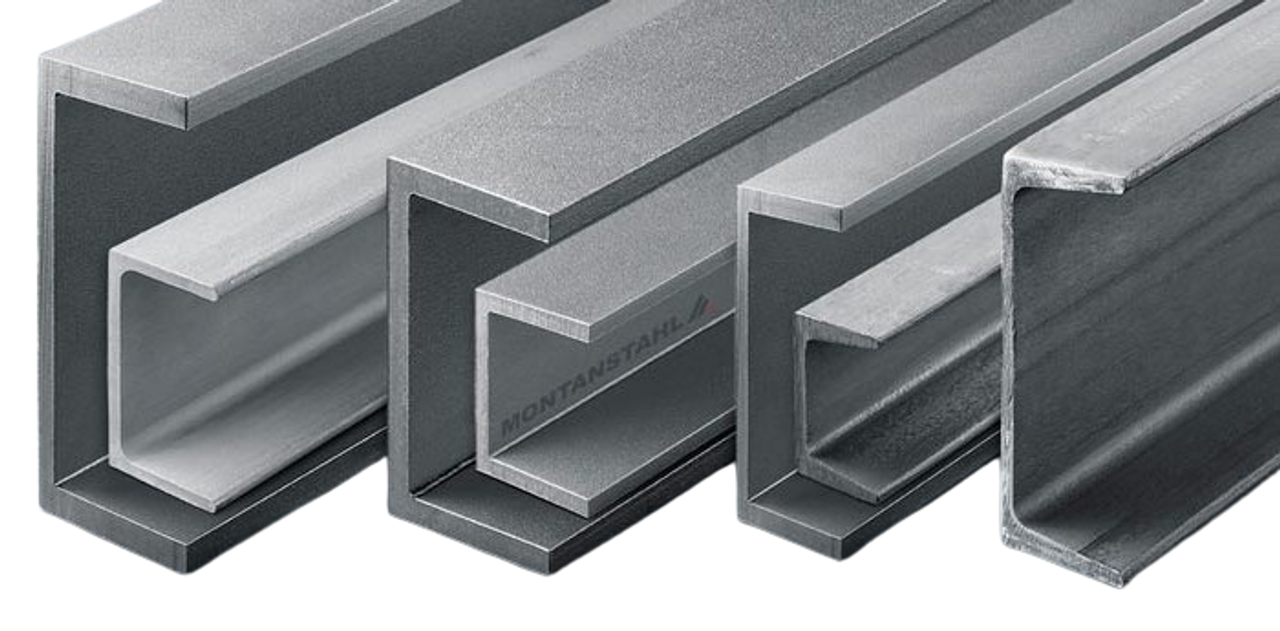

Structural Steel Channel 80x40 UPN(L) x6mm

Factors to Consider for Structural Steel Material Selection

1. Structural Requirements

When selecting Structural Steel for construction projects, several key structural requirements need to be considered. These requirements ensure that the chosen material can effectively bear loads, provide the necessary strength, and maintain structural stability and rigidity. The following factors should be carefully evaluated:

Load-bearing capacity:

The load-bearing capacity of Structural Steel refers to its ability to support and carry various loads without experiencing excessive deflection or failure. It is crucial to assess the anticipated loads that the structure will be subjected to, such as dead loads (the weight of the structure itself), live loads (occupant or environmental loads), and dynamic loads (e.g., wind, earthquakes).

The selected Structural Steel material should have a sufficient load-bearing capacity to withstand these loads, ensuring the safety and integrity of the structure. Engineers and designers use various calculations and analysis methods to determine the required strength and load-bearing capacity of the Structural Steel components.

Strength-to-weight ratio:

The strength-to-weight ratio is a vital factor in material selection, as it determines how efficiently a material can resist applied loads while keeping the weight of the structure at a minimum. Structural Steel exhibits an excellent strength-to-weight ratio, making it advantageous in construction projects where weight reduction is desirable.

A high strength-to-weight ratio allows for the design of lighter structures without compromising their strength and load-bearing capacity. This feature not only contributes to cost savings in material procurement and transportation but also simplifies construction processes and reduces the foundation requirements.

Structural stability and rigidity:

Structural stability refers to the ability of the chosen material to maintain its shape and resist deformation under the applied loads. Rigidity, on the other hand, refers to the material's resistance to bending or flexing.

In structural applications, it is crucial to ensure that the selected Structural Steel material offers adequate structural stability and rigidity to prevent excessive deflection, sagging, or collapse. The material should possess the necessary stiffness to maintain the structural shape and support loads without compromising the overall stability of the structure.

Factors such as the cross-sectional shape and dimensions of the Structural Steel components, as well as the design and connections used, play a significant role in achieving the desired structural stability and rigidity.

Structural Steel H-beam 160 IPE 6x3 Hellog

2. Environmental Factors

Environmental factors play a crucial role in material selection for construction projects. These factors ensure that the chosen Structural Steel material can withstand the challenges posed by the surrounding environment. When considering Structural Steel for different applications, three significant environmental factors to evaluate are corrosion resistance, fire resistance, and resistance to extreme temperatures and weather conditions.

Corrosion resistance:

Corrosion is a natural process that can significantly impact the structural integrity and durability of materials, especially in environments with high moisture levels or exposure to corrosive substances. It is essential to select Structural Steel materials with good corrosion resistance to ensure their long-term performance.

Various methods can enhance the corrosion resistance of Structural Steel, including the use of corrosion-resistant coatings, such as galvanizing or painting, or the application of stainless steel alloys. These protective measures create a barrier between the steel surface and the corrosive elements, preventing or slowing down the corrosion process.

The choice of corrosion-resistant Structural Steel is particularly crucial in coastal areas, industrial environments, and structures exposed to harsh weather conditions or chemical exposure. Proper maintenance and periodic inspections are also necessary to identify and address any signs of corrosion promptly.

Fire resistance:

Fire resistance is a vital consideration in material selection, as it determines how well a structure can withstand fire and minimize fire-related risks. Structural Steel's behavior in fire conditions is influenced by its composition, size, shape, and exposure time to elevated temperatures.

Structural Steel inherently has good fire resistance characteristics. It does not contribute fuel to the fire and retains its strength even at high temperatures. However, as temperatures increase, Structural Steel can lose its load-bearing capacity, leading to structural failure.

To enhance the fire resistance of Structural Steel, fire protection measures are employed, such as the application of fire-resistant coatings, intumescent paints, or the use of fire-resistant insulation materials. These measures help to delay the rise in steel temperature during a fire, allowing for more time for evacuation and firefighting efforts.

The level of fire resistance required for a specific application depends on the building code regulations, occupancy type, and project specifications. Adequate fire protection measures should be implemented based on the project's fire safety objectives.

Resistance to extreme temperatures and weather conditions:

Structural Steel materials should also exhibit resistance to extreme temperatures and weather conditions, ensuring their performance and longevity. Structures can be exposed to a wide range of temperature variations, from freezing temperatures to intense heat.

Structural Steel should have a low coefficient of thermal expansion, which allows it to expand and contract without causing excessive stresses or deformations. This characteristic helps the material withstand temperature fluctuations without compromising its structural integrity.

Additionally, Structural Steel should possess good weather resistance to withstand various environmental conditions such as UV radiation, moisture, wind, and atmospheric pollutants. Proper surface coatings and protective finishes can provide additional weather resistance, preventing degradation and extending the lifespan of the material.

Considering these structural requirements during the material selection process allows for the appropriate choice of Structural Steel that can effectively bear loads, provide the necessary strength, and ensure the stability and rigidity of the structure. By analyzing and understanding the specific structural demands of the project, engineers and designers can select the most suitable Structural Steel material to meet the desired performance goals and ensure a safe and reliable construction.

3. Design Flexibility

Design flexibility is a critical factor to consider when selecting Structural Steel for different applications in construction. The ability of Structural Steel to adapt to various architectural requirements, customization options, and compatibility with other construction materials can significantly influence the success and efficiency of a project. The following aspects highlight the design flexibility offered by Structural Steel:

Architectural requirements:

Structural Steel provides tremendous freedom and versatility in meeting diverse architectural requirements. Its high strength-to-weight ratio allows for the creation of open and spacious interiors with large column-free spaces, enabling architects to design structures with innovative and striking designs.

The inherent strength of Structural Steel allows for the creation of slender and elegant structural elements, such as beams and columns, reducing the visual impact and maximizing usable space. The material's ability to span long distances enables the construction of wide expanses without the need for intermediate support, further enhancing design possibilities.

Structural Steel also allows for the integration of various architectural features, such as cantilevers, arches, and curved elements, enabling the realization of unique and aesthetically pleasing designs. The flexibility offered by Structural Steel empowers architects to push the boundaries of creativity and create iconic structures.

Customization and fabrication possibilities:

Structural Steel offers extensive customization and fabrication possibilities, allowing for tailored solutions to meet specific project requirements. The material can be easily shaped, cut, and welded into different configurations, facilitating the realization of complex geometries and intricate designs.

The ability to fabricate Structural Steel components off-site in controlled manufacturing environments enhances construction efficiency, quality control, and project timelines. Fabrication techniques such as computer numerical control (CNC) cutting and automated welding ensure precision and accuracy in creating customized steel elements.

Structural Steel can also be prefabricated into modular units, facilitating faster on-site assembly and reducing construction time. This modular approach not only enhances productivity but also allows for easy future modifications or expansions.

Compatibility with other construction materials:

Structural Steel exhibits excellent compatibility with various other construction materials, enabling hybrid construction systems that leverage the strengths of different materials. It can be seamlessly integrated with concrete, timber, glass, and other materials to create hybrid structures that optimize the benefits of each material.

For instance, combining Structural Steel with concrete in composite construction allows for efficient load-bearing systems with enhanced strength and stiffness. This combination results in cost-effective structures that capitalize on the speed and flexibility of steel and the durability and fire resistance of concrete.The compatibility of Structural Steel with other materials also extends to architectural finishes and cladding systems. Steel frames can support a wide range of cladding materials, such as glass, stone, or metal panels, providing designers with aesthetic options to achieve the desired visual appearance.The design flexibility offered by Structural Steel provides architects, engineers, and designers with the freedom to create unique and visually appealing structures while ensuring structural integrity and performance. The ability to customize and fabricate Structural Steel components, as well as its compatibility with other materials, allows for efficient construction processes, cost optimization, and the realization of architecturally striking buildings.

4. Cost Considerations

Cost is a crucial factor to consider when selecting Structural Steel for construction projects. Evaluating the various cost components associated with Structural Steel helps in making informed decisions that align with budgetary constraints while ensuring optimal value and long-term cost-effectiveness. The following aspects highlight the cost considerations related to Structural Steel:

Material and fabrication costs:

The cost of the Structural Steel material itself is an important factor to assess during the selection process. Factors such as the type, grade, and quantity of Structural Steel required for the project can significantly impact material costs. It is essential to compare prices from different suppliers and consider the availability of the desired material in the local market.

Additionally, fabrication costs should be taken into account. Structural Steel components often require custom fabrication, including cutting, welding, drilling, and surface treatments. The complexity of the design, detailing requirements, and customization options can influence the fabrication costs. Obtaining quotes from reputable fabricators and assessing their capabilities and track record can help in estimating the fabrication costs accurately.

Installation and construction costs:

The installation and construction costs associated with Structural Steel are also important considerations. The efficiency of the construction process, the availability of skilled labor, and the ease of handling and assembling Structural Steel components can impact the overall installation costs.

Structural Steel offers advantages in terms of speed and ease of construction, especially when compared to traditional materials like concrete. Its prefabrication potential allows for faster on-site assembly, reducing labor costs and construction time. The lightweight nature of Structural Steel also facilitates ease of handling and transportation, contributing to cost savings.

The project's location, site conditions, and access to the construction site can also influence installation costs. Assessing these factors and considering the efficiency and productivity gains associated with Structural Steel can provide a more accurate estimation of installation and construction costs.

Maintenance and lifecycle costs:

Another critical aspect of cost considerations is the maintenance and lifecycle costs associated with Structural Steel. The long-term durability, performance, and maintenance requirements of the selected material can impact the overall lifecycle costs of the structure. Structural Steel is known for its durability and resistance to degradation, requiring minimal maintenance over its lifespan. Regular inspections, surface treatments, and corrosion protection measures can help extend the life of Structural Steel components and minimize maintenance costs.

Comparatively, Structural Steel's maintenance costs are typically lower than materials that may require more frequent repairs or replacements. The ability of Structural Steel to withstand environmental factors, such as corrosion and weather conditions, reduces the need for ongoing maintenance and associated costs. Considering the maintenance and lifecycle costs of Structural Steel is essential for a comprehensive cost analysis. Evaluating the projected lifespan of the structure, the anticipated maintenance requirements, and the expected frequency of repairs or replacements enables a more accurate assessment of the long-term costs associated with Structural Steel.

By carefully evaluating the material and fabrication costs, installation and construction costs, as well as maintenance and lifecycle costs, stakeholders can make informed decisions regarding Structural Steel selection. Balancing upfront costs with long-term cost-effectiveness ensures that the chosen material aligns with the project budget while delivering value, durability, and optimal performance over the life of the structure.

5 Sustainability and Environmental Impact

In recent years, the consideration of sustainability and environmental impact has become increasingly important in construction projects. The choice of materials, including Structural Steel, can significantly influence a project's sustainability goals and environmental footprint. When selecting Structural Steel for different applications, several key factors related to sustainability and environmental impact should be carefully evaluated:

Recyclability and reuse potential:

Structural Steel is highly recyclable, making it a sustainable choice for construction projects. At the end of a structure's life cycle, steel components can be recycled and transformed into new steel products, reducing the demand for virgin materials and minimizing waste. The recyclability of Structural Steel contributes to the conservation of natural resources and helps mitigate the environmental impact associated with material extraction and production.

Furthermore, the reuse potential of Structural Steel components adds to its sustainability credentials. Steel elements from demolished structures can often be salvaged and repurposed in other projects, extending their service life and reducing the need for new manufacturing.

Energy efficiency:

Energy efficiency is a critical aspect of sustainability in construction. Structural Steel exhibits excellent energy efficiency characteristics, contributing to reduced energy consumption throughout a structure's life cycle. The lightweight nature of steel enables efficient transportation and installation, reducing energy requirements during construction.

Additionally, the thermal properties of Structural Steel allow for the efficient insulation and temperature regulation of buildings, reducing the energy needed for heating and cooling. Composite construction systems that combine Structural Steel with other materials, such as concrete, can enhance energy efficiency by optimizing the thermal performance of the structure.

Design considerations, such as the use of insulated wall panels, energy-efficient glazing systems, and efficient HVAC (heating, ventilation, and air conditioning) systems, further enhance the energy performance of structures incorporating Structural Steel.

Environmental certifications and standards:

Various environmental certifications and standards exist to guide and assess the sustainability performance of construction materials, including Structural Steel. Certifications such as Leadership in Energy and Environmental Design (LEED) and Building Research Establishment Environmental Assessment Method (BREEAM) provide frameworks for evaluating and promoting sustainable construction practices.

Structural Steel manufacturers and suppliers may also adhere to specific environmental standards, such as ISO 14001 (Environmental Management System) or certifications from sustainability-focused organizations. These certifications demonstrate a commitment to reducing environmental impact, promoting responsible manufacturing practices, and ensuring the traceability and sustainability of the supplied materials.

By selecting Structural Steel materials that align with recognized environmental certifications and standards, construction projects can demonstrate their commitment to sustainability and meet the requirements of green building initiatives.

Considering the recyclability and reuse potential of Structural Steel, its energy efficiency characteristics, and adherence to environmental certifications and standards allows construction professionals to make sustainable choices that minimize the environmental impact of their projects. Incorporating sustainable materials like Structural Steel not only reduces the carbon footprint but also promotes resource conservation, waste reduction, and a more sustainable built environment.

Structural Steel Sheet Pile 12mm Hellog

Application of structural steel grade in Nigeria

The Low carbon steel grades have a wide range of uses in various industries in Nigeria. Let's explore some of the key applications:

1. Steel Frame Buildings:

Low carbon steel is often chosen for constructing steel frame buildings due to its unique structural properties. It provides sufficient strength to meet seismic and wind requirements while offering durability. Additionally, low carbon steel is resistant to damage from insects, impervious to rot, and has excellent fire resistance. These qualities make it a reliable choice for constructing sturdy and long-lasting building frames.

2. Machinery Parts:

Low carbon steel is widely used in the manufacturing of machinery parts. It is a combination of carbon and iron, and the ratio of these elements determines the strength, ductility, and hardness of the steel. The malleability of low carbon steel allows for easy shaping and working without the risk of breaking. This makes it ideal for fabricating machine parts, including steel sheets used in car body panels.

3. Cookware:

While stainless steel is commonly used in cookware, there is a market for carbon steel cookware as well. Low carbon steel, in particular, offers advantages such as rust resistance, the ability to hold an edge, and excellent temperature resistance. With proper treatment, low carbon steel can become essentially non-stick and maintain sharpness for longer periods. Although it requires more care and maintenance, it provides enhanced performance for discerning chefs.

4. Pipelines:

Low carbon steel tubes, especially galvanized plain carbon steel tubes, are extensively used as poles and piles for their exceptional ductility. They are essential materials for withstanding harsh weather conditions and environments. Steel pipelines made from low carbon steel are widely employed in water transportation, natural gas distribution, and even beer pipelines. These pipes are easily welded and offer flexibility to prevent cracking or breaking under pressure. In cold climates, they can be insulated to ensure optimal performance and prevent structural issues.

5. Metal Gates/Fencing:

Low carbon steel is a preferred material for manufacturing aesthetically pleasing metal gates and fencing. It combines strength with durability, making it difficult to break. It can be machined and welded to achieve desired designs, and it can be painted for a longer-lasting and low-maintenance finish. Galvanizing the steel adds an extra layer of zinc coating, providing protection against corrosion and enhancing its longevity.

These are just a few examples of how low carbon steel grades are utilized in Nigeria. The versatility, strength, and corrosion resistance of low carbon steel make it a valuable material across various industries, contributing to the development of infrastructure, machinery, and everyday products.

Key advantages and benefits of using Structural Steel in construction

The use of Structural Steel in construction offers several significant advantages and benefits:

1. Strength and Durability:

Structural Steel is renowned for its exceptional strength and durability. It can withstand heavy loads, impacts, and extreme weather conditions, making it suitable for structures requiring high structural integrity and longevity.

2. Design Flexibility:

Structural Steel provides architects and engineers with tremendous design flexibility. Its high strength-to-weight ratio allows for the creation of open and spacious interiors, large spans, and unique architectural features. The material can be easily shaped and fabricated into various configurations, enabling innovative and aesthetically pleasing designs.

3. Speed and Efficiency:

The prefabrication potential of Structural Steel allows for faster construction and reduced project timelines. Structural Steel components can be manufactured off-site, ensuring precision and quality control, and then assembled quickly on-site. This streamlined construction process saves time and reduces labor costs.

4. Sustainability:

Structural Steel is a sustainable construction material. It is highly recyclable, contributing to the conservation of natural resources and reducing waste. The material's long lifespan, low maintenance requirements, and potential for reuse make it an environmentally friendly choice.

5. Cost-Effectiveness:

The efficient use of Structural Steel, combined with its design flexibility and fast construction times, can lead to cost savings. Its lightweight nature reduces foundation requirements and transportation costs. Additionally, the material's durability and low maintenance needs contribute to long-term cost-effectiveness.

Conclusion

Selecting the right Structural Steel for a specific application is a complex process that requires a thorough evaluation of various factors. It is crucial to engage with professionals, such as structural engineers, architects, and steel suppliers, who possess expertise in working with Structural Steel. These professionals can provide valuable insights, technical knowledge, and practical advice tailored to the specific project requirements.

In conclusion, the selection of Structural Steel for different applications in construction should be approached with careful consideration and informed decision-making. Each project has unique requirements and goals, and understanding the factors discussed in this article will empower you to make well-informed choices. By evaluating factors such as structural requirements, environmental considerations, design flexibility, cost considerations, and sustainability, you can determine the most appropriate type of Structural Steel that aligns with your project's objectives. Collaboration with professionals and steel suppliers will enhance the decision-making process, ensuring that your project benefits from the strength, durability, and versatility of Structural Steel.

Remember, selecting the right Structural Steel material sets the foundation for a successful construction project, impacting its performance, safety, and long-term viability. By making informed decisions based on thorough evaluations and consultations, you can maximize the benefits of Structural Steel and create structures that stand the test of time.

Contact our expert at GZ Industrial supplies for more enquiries

Recent Posts

-

How to Choose the Right Industrial Cleaning Service Provider

Key takeawayThoroughly Assess Your Needs and Providers: Understand your specific industrial cle …Jul 26, 2024 -

Floor Paint Maintenance: How to Keep Your Floors Looking Their Best

Maintaining your painted floors is essential for preserving their beauty and extending their lifespa …Jul 25, 2024 -

The Best Floor Paint for Different Types of Flooring

When it comes to revitalizing your home's flooring, choosing the right paint can make all the d …Jul 19, 2024