How to Choose the Right Construction Chemicals

Introduction

Selecting the right construction chemicals is a pivotal decision that can greatly impact the longevity, strength, and overall quality of any building project. Whether you're an experienced contractor, a budding DIY enthusiast, or simply someone interested in understanding the intricacies of construction materials, this guide will prove invaluable in navigating the world of construction chemicals. From admixtures and sealants to waterproofing agents and concrete repair materials, the choices can be overwhelming. It's not just about picking the most expensive or the most popular product; it's about finding the construction chemicals that precisely align with your project's unique requirements, specifications, and environmental considerations.

Read more...Essential Construction Chemicals: A Builder's Guide

Key Takeaway

- Understand Project Requirements – Identify whether your project needs waterproofing, bonding, strengthening, or protection against environmental factors.

- Evaluate Environmental Conditions – Consider climate factors, material compatibility, and exposure to chemicals or pollutants.

- Prioritize Strength and Durability – Choose chemicals that enhance structural integrity, improve longevity, and resist wear and tear.

- Review Technical Specifications – Check the manufacturer’s datasheets for performance characteristics, application guidelines, and safety precautions.

Buy Online... Dr. Fixit 302 Super Latex 20Kg

One crucial tip to choose the right construction chemicals is to thoroughly assess your project's specific needs and requirements. Not all construction chemicals are created equal, and each product is formulated to address distinct challenges. Before making a selection, carefully analyze factors such as the type of construction material, environmental conditions, and the desired performance characteristics. Are you looking to enhance concrete strength, waterproof a structure, or repair damaged surfaces? By identifying your project's precise goals and challenges, you can narrow down the options and choose the construction chemicals that best match your needs, ensuring a successful and cost-effective solution.

In this comprehensive guide, we will delve into the essential factors you need to consider when choosing construction chemicals, helping you make informed decisions that contribute to the success and sustainability of your construction endeavors. Whether you aim to fortify the structural integrity of a skyscraper or simply seal your home's driveway, this guide will equip you with the knowledge you need to select the right construction chemicals for the job.

Factors to Consider When Choosing Construction Chemicals

Construction chemicals play important roles in virtually all sorts of construction projects whether industrial, residential, or commercial building projects. They can be used with various elements in different applications for improving important quality of construction material such as durability, workability, and sustainability of the structures and the following factors will aid you in making the right decision.

Performance Requirements

The performance requirements of construction chemicals are central to selecting the right products for your project. Consider the specific performance attributes you need, which may include:

- Strength Enhancement: If your project demands increased structural strength, you'll require construction chemicals that enhance the compressive, tensile, and flexural strength of materials like concrete or mortar.

- Durability: Some projects, especially those in harsh environments or subject to heavy wear and tear, require chemicals that improve durability, reducing the risk of degradation over time.

- Adhesion and Bonding: When joining various construction materials, such as concrete to steel or masonry to wood, adhesives and sealants with excellent adhesion properties are essential.

- Waterproofing: In projects exposed to moisture or water, selecting waterproofing agents can prevent water infiltration, protecting structures from damage and deterioration.

- Chemical Resistance: For projects in industrial or chemical environments, chemicals should be chosen for their resistance to specific chemicals or corrosive substances.

- Fire Resistance: In structures where fire safety is a concern, fire-resistant coatings and materials can be crucial.

Compatibility with Existing Materials

When choosing construction chemicals, consider how well they will integrate with the existing materials in your project. Compatibility is vital to ensure that the chemicals won't negatively affect the performance or aesthetics of the structure. For instance, when adding admixtures to concrete, ensure that they do not compromise the curing process or lead to undesired side effects.

Long-Term Durability

Long-term durability is a critical factor, especially in construction projects where the expected lifespan is extensive. Construction chemicals should be chosen to withstand the test of time, maintaining their effectiveness and performance over the years. Look for products that offer longevity and resistance to environmental factors, such as UV radiation, moisture, and temperature fluctuations.

Cost Considerations

Budget constraints are a reality in construction projects, and cost considerations play a significant role in chemical selection. While it's essential to choose high-quality chemicals that meet your project's needs, it's equally important to balance these requirements with the available budget. Consider not only the upfront costs of the chemicals but also the long-term savings they may provide through increased durability and reduced maintenance.

Environmental Impact

In today's environmentally conscious world, it's crucial to consider the environmental impact of the construction chemicals you choose. Look for products that are eco-friendly and comply with environmental regulations. Sustainable construction chemicals can help reduce the carbon footprint of your project and contribute to a greener future. Consider factors such as VOC (volatile organic compound) emissions and recyclability when making your choices.

Buy Online... Dr Fixit Raincoat 601 20L

Types of Construction Chemicals

Admixtures

Admixtures are chemical additives used in concrete, mortar, or grout to enhance specific properties. These include:

- Plasticizers: Improve workability and reduce water content.

- Superplasticizers: Enhance the flow and workability of concrete.

- Accelerators: Speed up the setting and curing process.

- Retarders: Delay the setting of concrete for specific applications.

- Air-Entraining Agents: Introduce tiny air bubbles for freeze-thaw resistance.

- Corrosion Inhibitors: Protect reinforced steel from corrosion.

Sealants and Adhesives

Sealants and adhesives are essential for sealing gaps, joints, and bonding various construction materials. Common types include:

- Silicone Sealants: Resistant to moisture, weather, and UV radiation.

- Polyurethane Sealants: Flexible and durable, suitable for various applications.

- Epoxy Adhesives: High-strength bonding for a wide range of materials.

- Construction Adhesives: Used for attaching structural components.

Waterproofing Agents

Waterproofing agents are crucial in preventing water infiltration and include:

- Membranes: Applied as sheets or liquid to form a barrier.

- Coatings: Applied as liquid and form a protective film.

- Integral Waterproofing Additives: Added directly to concrete or mortar mixes.

Concrete Repair and Restoration Materials

These materials are used to repair and restore deteriorating concrete structures, including:

- Repair Mortars: Used for patching and resurfacing damaged concrete.

- Epoxy Resins: Bonding and sealing for structural repairs.

- Corrosion Protection Systems: Prevent corrosion in reinforced concrete structures.

Surface Treatments

Surface treatments enhance the appearance and durability of construction materials:

- Coatings and Paints: Protect surfaces from environmental factors, including UV exposure and staining.

- Protective Films: Transparent or colored films that safeguard surfaces.

- Concrete Stains and Dyes: Used for decorative purposes and to alter the appearance of concrete.

Buy Online... Dr Fixit Krystalline 107

Read more...Where to Buy Construction Chemicals in Nigeria

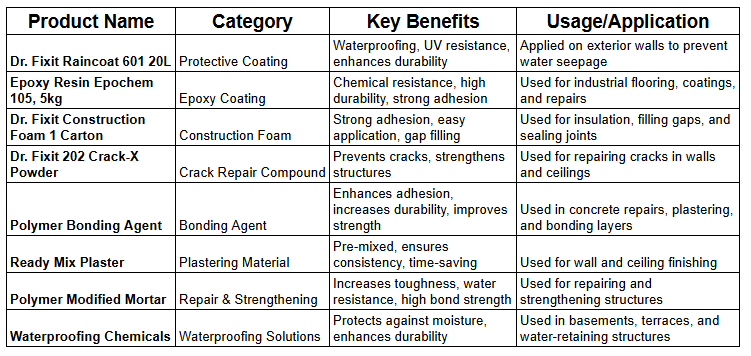

Best Construction Chemicals for Durability, Strength, and Waterproofing

Selecting the Right Construction Chemicals

Selecting the right construction chemicals for your project is a critical step in ensuring the success and longevity of the structure. To make informed choices, it's essential to follow a systematic approach, considering factors like performance, compatibility, environmental impact, and cost-effectiveness. Here are key strategies for selecting the right construction chemicals:

Research and Product Comparison

- Identify Your Options: Begin by identifying a range of construction chemicals that might meet your project's requirements. You can do this by consulting industry publications, online resources, and product catalogs from reputable manufacturers.

- Performance Considerations: Examine the performance characteristics of each chemical option in your list. Look at factors like compressive strength enhancement, adhesion properties, resistance to environmental factors, and other relevant performance indicators. This research will help you determine which chemicals are best suited to meet your project's specific goals.

- Reviews and Case Studies: Look for reviews, case studies, and testimonials from professionals who have used these products in similar applications. These real-world experiences can provide valuable insights into a product's performance and reliability.

- Comparative Testing: If possible, conduct comparative testing by obtaining samples of different chemicals and evaluating their performance in a controlled environment. This hands-on approach can offer direct insight into how the products will behave in your project.

- Cost-Benefit Analysis: Consider the cost of each chemical relative to its performance and the long-term benefits it provides. Sometimes, a slightly more expensive product may offer significant savings in terms of maintenance and longevity.

Reading and Understanding Product Labels

- Product Data Sheets: Product data sheets are valuable sources of information provided by manufacturers. These sheets contain essential details about the product, such as its composition, physical properties, recommended applications, and safety precautions. Review these data sheets thoroughly to understand what each chemical product entails.

- Safety Data Sheets (SDS): Safety Data Sheets are crucial for understanding the safety and handling requirements of construction chemicals. They provide information on potential hazards, first-aid measures, storage instructions, and more. Be sure to familiarize yourself with the SDS of any product you plan to use.

- Technical Specifications: Pay attention to the technical specifications of construction chemicals. These specifications include information about the chemical's performance under various conditions. Ensure that the product's specifications align with the requirements of your project.

- Environmental Impact: Manufacturers often include information about the environmental impact of their products. Look for details on VOC emissions, recyclability, and compliance with green building standards like LEED (Leadership in Energy and Environmental Design).

- Compatibility: Check whether the product is compatible with the other materials in your project. Incompatibility can lead to performance issues or even damage.

- Storage and Shelf Life: Take note of storage requirements and shelf life. Improper storage can affect the quality and effectiveness of construction chemicals.

Seeking Expert Advice

- Consult with Experts: Seek advice from experts in the construction industry, including structural engineers, architects, and experienced contractors. They can provide valuable insights and recommendations based on their practical experience with construction chemicals.

- Manufacturer Support: Manufacturers often have technical support teams that can answer your questions and provide guidance. Reach out to them to clarify any doubts and get assistance in selecting the right chemicals for your project.

- Collaboration with Suppliers: Work closely with suppliers and distributors like Epoxy Oilserv Nigeria Limited who have in-depth knowledge of construction chemicals. They can help you navigate the wide array of options and guide you toward suitable choices.

- Consider Local Conditions: Local climate and environmental conditions can significantly impact the choice of construction chemicals. Experts familiar with the region can offer advice specific to the local environment.

Buy Online... EPOCHEM 304/404 Epoxy Floor Sealers

Proper Application and Usage of Construction Chemical

Storage and Handling of Construction Chemicals

Proper storage and handling of construction chemicals are crucial to ensure their effectiveness and safety throughout a project. Here are important considerations:

- Storage Conditions: Construction chemicals often have specific storage temperature and humidity requirements. Ensure they are stored within the recommended conditions to prevent degradation or spoilage. Proper storage can extend the product's shelf life.

- Ventilation: Some chemicals may emit fumes or gases that can be harmful when inhaled. Store chemicals in well-ventilated areas or use fume hoods to minimize exposure to harmful substances.

- Segregation: Store chemicals separately to prevent unwanted reactions or contamination. Follow the manufacturer's guidelines regarding compatibility and segregation.

- Labeling: Clearly label all containers with the name of the chemical, its contents, and any relevant safety information. This helps in quick identification and ensures safe handling.

- Handling Equipment: Use appropriate handling equipment and personal protective gear when working with construction chemicals. Safety measures should include wearing gloves, goggles, and protective clothing as necessary.

Correct Application Techniques

The proper application of construction chemicals is essential to achieve the desired results and maintain structural integrity. Here are key considerations:

- Surface Preparation: Ensure that the surfaces to which the chemicals will be applied are clean and free from contaminants. Proper preparation may involve cleaning, sanding, or other treatments.

- Mixing and Application: Follow the manufacturer's instructions for mixing ratios and application techniques. Some chemicals require precise mixing, while others may be ready to use. Apply chemicals evenly and consistently to avoid issues like streaking or uneven coverage.

- Curing Time: Allow adequate curing time, which varies depending on the type of chemical and environmental conditions. Rushing the curing process can compromise the chemical's effectiveness.

- Temperature and Weather Conditions: Consider the ambient temperature and humidity during application. Extreme temperatures or adverse weather conditions can impact the application and curing process. Special precautions may be needed in such situations.

- Tools and Equipment: Use appropriate tools and equipment for application. Whether it's brushes, rollers, sprayers, or trowels, the right equipment can make a significant difference in the quality of the application.

- Overapplication or Underapplication: Be cautious not to overapply or underapply construction chemicals. Follow the recommended application rates to avoid issues like excessive material consumption or insufficient coverage.

Ensuring Safety Measures

Safety should be a top priority when working with construction chemicals. Here are key safety measures:

- Personal Protective Equipment (PPE): Ensure that all personnel involved in handling or applying construction chemicals wear the appropriate PPE, including gloves, eye protection, respirators, and protective clothing.

- Ventilation: Maintain good ventilation in the work area to reduce exposure to fumes or airborne particles. Use exhaust fans or wear respirators as necessary.

- Emergency Response: Have an emergency response plan in place. Know the location of emergency showers, eye wash stations, and fire extinguishers. Train personnel in responding to chemical spills or accidents.

- Material Safety Data Sheets (MSDS): Keep MSDS for all chemicals on site and make them readily accessible. MSDS provide critical information on the hazards, handling, and first-aid measures for each chemical.

- Training: Provide proper training for all personnel involved in the handling and application of construction chemicals. This training should cover the safe use, storage, and disposal of these substances.

- Chemical Compatibility: Be aware of the potential for chemical reactions between different products. Some chemicals may react violently when mixed. Always consult MSDS and manufacturer guidelines.

Buy Online... Dr. Fixit 202 Crack-X Powder

Maintenance and Monitoring Guide when using Construction Chemical

Regular Inspections and Maintenance

Once construction chemicals are applied, regular inspections and maintenance are vital for long-term durability and performance:

- Scheduled Inspections: Implement scheduled inspections to assess the condition of surfaces treated with construction chemicals. This can help identify any signs of degradation, damage, or wear and tear.

- Maintenance Procedures: Develop a maintenance plan that includes procedures for reapplication or touch-ups when needed. Regular maintenance can extend the life of the treated surfaces.

- Cleaning: In some cases, cleaning may be necessary to remove contaminants that have accumulated on the treated surface. Use appropriate cleaning methods and chemicals that are compatible with the construction chemicals applied.

- Repairs: Address any damage promptly. If there are cracks, leaks, or other issues, use the appropriate repair materials and methods specified by the manufacturer.

Adapting to Changing Conditions

Construction projects can face changing environmental conditions and requirements over time. Consider the following:

- Environmental Changes: Climate change and environmental regulations may evolve. Ensure that your project remains compliant with any new environmental standards that arise.

- Upkeep of Protective Coatings: Protective coatings applied as construction chemicals may require periodic maintenance or reapplication to maintain their effectiveness.

- Structural Load Changes: As the load or usage of a structure changes over time, reevaluate whether the initially selected construction chemicals are still suitable for the new conditions.

Buy Online... Dr. Fixit 603 Newcoat

Related Article

Which Construction Chemical is used for Waterproofing?

6 BEST INDUSTRIAL CLEANING CHEMICALS IN NIGERIA 2023

Conclusion

Choosing the right construction chemicals is a critical aspect of any construction project, and it involves considering factors such as performance requirements, compatibility, long-term durability, cost, and environmental impact. By selecting the most suitable chemicals, you can enhance the structural integrity and longevity of the project while adhering to environmental standards and budget constraints.

This guide provides a comprehensive overview of the considerations and best practices for selecting, applying, and maintaining these chemicals. By following these guidelines and seeking expert advice when needed, individuals and professionals can ensure that construction projects are executed safely, efficiently, and with the highest level of quality and longevity in mind. Proper storage, handling, application, and monitoring are all critical aspects of achieving success in construction endeavors while minimizing risks and maximizing the benefits of construction chemicals.

Don't compromise on quality shop now at GZ Industrial Supplies and build with confidence!