MECHANISM OF HYDRAULIC HOSE CRIMPING MACHINE

Key takeaway

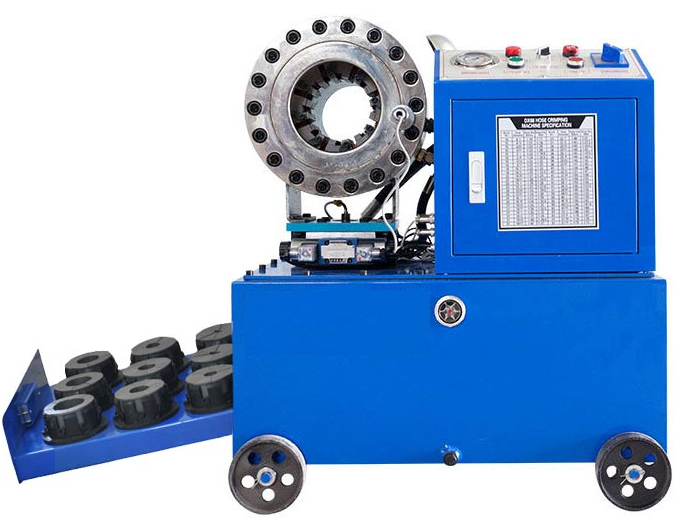

A hydraulic crimping hose machine is mainly used to fabricate hose assembly, and to connect to the end of a hose of many sizes. Two pieces of the hose are joined by crimping either one or both parts so that they hold on to each other. Hydraulic hose crimping machines are used for more demanding applications such as industrial hose crimping, metal forming, shop floor production runs, and machine shop maintenance. At the outer diameter of the metal or material that needs to be joined with the hose, a hydraulic hose crimping machine uses a force of 360 degrees.

Buy Online... Hydraulic Hose Crimping Machine 800W DF68 KAIDA

Introduction

In the dynamic world of hydraulic systems, the underpinning of reliability and safety often rests in the secure and precise connection of hydraulic hoses. At the heart of this fundamental process lies a remarkable piece of machinery – the hydraulic hose crimping machine. In this section, we will embark on a journey to unveil the essence of these machines, their pivotal role in hydraulic systems, and provide a sneak peek into the primary focus of this guide – unraveling the intricate mechanism behind their operation.

A hydraulic hose crimping machine, in its simplest form, is a specialized device engineered to create permanent, secure connections between hoses and connectors in hydraulic systems. These machines utilize a combination of force and precision to reshape the hose and connector, effectively "crimping" them together. This process ensures a leak-free connection that can withstand the immense pressures and demands of hydraulic systems, whether in heavy machinery, industrial equipment, or aerospace applications.

Hydraulic systems are the lifeblood of many industries, providing the power and control needed to perform tasks ranging from lifting heavy loads to steering aircraft. The integrity of these systems hinges on the quality of hose connections. A failure in hose crimping can lead to leaks, reduced system performance, and even catastrophic failures. In essence, the hydraulic hose crimping machine is the guardian of fluid power, ensuring that hydraulic systems function reliably and efficiently.

While the importance of hydraulic hose crimping machines in hydraulic systems is undeniable, our guide's primary focus is on uncovering the mechanism that makes these machines tick. We will take you on a detailed journey through the various components of these machines, their operation, and the role they play in creating precise and secure hose connections. By the end of this guide, you will gain a profound understanding of how these machines operate and the critical role they play in maintaining the integrity of hydraulic systems. Join us in exploring the fascinating world of hydraulic hose crimping machine mechanisms.

Buy Online... Hydraulic Hose Crimping Machine 220V DX68 KAIDA

Understanding Hydraulic Hose Crimping

Hydraulic hose crimping is a mechanical process used to create a secure and reliable connection between hoses and fittings within hydraulic systems. Hydraulic hoses are flexible tubes that carry pressurized fluid in hydraulic systems, such as those used in industrial, agricultural, construction, and automotive applications. Hydraulic fittings are metal connectors that attach to the ends of hydraulic hoses, allowing them to connect to other components, such as pumps, valves, cylinders, or machines. Hydraulic hose crimping ensures that the hydraulic system functions efficiently, with minimal or no leakage, even under high-pressure conditions. Understanding how this process works is crucial for maintaining the integrity and safety of hydraulic systems.

Importance of Secure Hose Connections

Secure hose connections are the lifeblood of hydraulic systems. These connections ensure that hydraulic fluid flows without leakage or loss of pressure. Any compromise in these connections can lead to system failure, posing operational risks and safety hazards. Thus, comprehending the significance of secure hose connections is vital in hydraulic applications. Hydraulic systems operate under high pressures and temperatures, which can cause fluid leaks, bursts, or blow-offs if the connections are not properly sealed. Therefore, it is essential to follow the proper crimping procedures and use the appropriate tools and equipment.

There are different types of hoses and connectors used in hydraulic systems, depending on the application requirements and specifications. Some of the common types are:

Rubber hoses:

These are flexible and durable hoses made of synthetic rubber, reinforced with steel wire or textile braid. They can handle a wide range of pressures and temperatures and are resistant to abrasion, oil, and weather. They are suitable for general-purpose applications, such as water, air, oil, or gas transfer.

Thermoplastic hoses:

These are lightweight and flexible hoses made of thermoplastic materials, such as nylon, polyurethane, or polyester. They can handle moderate to high pressures and temperatures and are resistant to chemicals, corrosion, and UV rays. They are suitable for specialized applications, such as hydraulic jacks, rescue tools, or marine steering.

PTFE hoses:

These are hoses made of polytetrafluoroethylene (PTFE), a synthetic fluoropolymer with excellent chemical resistance and low friction. They can handle high pressures and temperatures and are resistant to almost all solvents, acids, bases, and fuels. They are suitable for demanding applications, such as chemical transfer, steam cleaning, or food processing.

Metal hoses:

These are rigid and durable hoses made of metal alloys, such as stainless steel or bronze. They can handle extreme pressures and temperatures and are resistant to fire, corrosion, and vibration. They are suitable for high-performance applications, such as aerospace, nuclear power, or cryogenics.

Straight fittings:

These are fittings that connect two hoses or components in a straight line. They have a male or female thread on one end and a hose barb on the other end. They are suitable for simple connections that do not require any change in direction.

Elbow fittings:

These are fittings that connect two hoses or components at an angle. They have a male or female thread on one end and a hose barb on the other end. The angle can vary from 30° to 90°. They are suitable for connections that require a change in direction.

Tee fittings:

These are fittings that connect three hoses or components in a T-shape. They have a male or female thread on one end and two hose barbs on the other end. They are suitable for connections that require a branch or a split.

Flange fittings:

These are fittings that connect two hoses or components using a flange system. They have a flange on one end and a hose barb on the other end. The flange is a flat rim with holes that aligns with another flange on the opposite component. The flanges are secured with bolts or clamps. They are suitable for connections that require high pressure or large diameter.

Components of a Hydraulic Hose Crimping Machine

A hydraulic hose crimping machine is composed of several key components that work together to create a secure and leak-free connection between hydraulic hoses and fittings. These components are:

Hydraulic Pump and Motor:

The hydraulic pump and motor are the power source of the machine, providing the hydraulic pressure and force needed to crimp the fitting onto the hose. The hydraulic pump converts mechanical energy from the electric motor into hydraulic energy, which is transmitted through the hydraulic fluid to the crimping head. The hydraulic motor controls the speed and direction of the crimping head, allowing for precise and consistent crimps.

Die sets and tooling:

The die sets and tooling are the parts of the machine that directly contact and deform the fitting and hose during the crimping process. The die sets are metal pieces that have a specific shape and size that match the fitting and hose diameter. They are mounted on the crimping head and can be changed according to the type of fitting and hose being crimped. The tooling includes the accessories that assist in the crimping process, such as the die holder, die ring, die cone, die pusher, etc.

Control Panel and Safety Features:

Modern hydraulic hose crimping machines are equipped with user-friendly control panels that allow operators to adjust settings, such as crimping force and time. The control panel may have digital or analog displays, buttons, switches, or knobs that enable the operator to set and view the desired settings. Additionally, these machines incorporate various safety features, including emergency stop buttons, safety shields, and sensors to prevent accidents and injuries during operation. Understanding how to operate the control panel and adhere to safety protocols is essential for the safe and efficient use of the machine.

Buy Online... Hydraulic Hose Crimping Machine 800W DF68 KAIDA

The Crimping Process Step by Step

The crimping process is the mechanism of creating a secure and leak-free connection between hydraulic hoses and fittings by applying a specific amount of force to deform them. The crimping process involves the following steps:

Hose Preparation and Insertion:

The process begins with preparing the hydraulic hose. This includes selecting the appropriate hose size and type, trimming it to the required length, and ensuring the hose's ends are clean and cut squarely. After preparing the hose, the operator inserts it into the die set, ensuring that the hose's end reaches the fitting's base.

Positioning and Securing the Hose:

Once the hose is correctly positioned within the die set, it's time to secure it for crimping. The machine's tooling, which consists of two halves of a die that precisely match the hose and fitting, is adjusted to encase the hose-fitting junction. Careful positioning and alignment are essential to achieve a secure and leak-free connection.

The crimping operation itself:

The third step is to perform the actual crimping operation by activating the crimping tool, which can be manual or automatic. The crimping tool uses hydraulic power to generate crimping force, which is transmitted through the hydraulic fluid to the crimping head. The crimping head then compresses the die sets, which in turn deform the terminal and hose, creating a tight and secure connection. The crimping force, pressure, speed, and diameter can be monitored and adjusted using a control panel, which may have digital or analog displays, buttons, switches, or knobs.

Release and removal of the crimped hose:

The final step is to release and remove the crimped hose from the crimping tool. The crimping tool has a release mechanism that allows the die sets to retract and release the hose and terminal. The hose and terminal can then be removed from the die sets and inspected for quality and consistency. The inspection methods may include visual inspection, pull test, cross-section analysis, micrograph analysis, electrical test, or dimensional test.

Hydraulic System in Detail

Hydraulic systems play a pivotal role in the crimping operation. They provide the force and pressure needed to compress the hose and fitting together effectively. A hydraulic pump, powered by an electric motor or an engine, pressurizes hydraulic fluid, generating force that is precisely controlled to ensure a secure and consistent crimp.

- Hydraulic Fluid and Its Functions: Hydraulic fluid is the lifeblood of the hydraulic system. It serves multiple critical functions, including:

- Transmitting Force: Hydraulic fluid is incompressible and can transmit force effectively, ensuring that the crimping operation is precise and reliable.

- Lubrication: The fluid also acts as a lubricant for various moving parts in the hydraulic system, reducing friction and wear.

- Heat Dissipation: It helps dissipate the heat generated during the crimping process, preventing the system from overheating.

- Seal Lubrication: Hydraulic fluid aids in maintaining and lubricating the seals that prevent leaks.

- Cleaning and Cooling: Hydraulic fluid cleans and cools system components, ensuring they operate efficiently and safely.

Pressure Control and Maintenance:

Controlling and maintaining hydraulic pressure are critical to the proper functioning of the crimping machine. The hydraulic system is equipped with components like pressure control valves and regulators that allow operators to adjust and maintain the pressure at optimal levels. This precise pressure control is vital for achieving consistent and high-quality hose crimps. To ensure optimal performance and longevity of the hydraulic system, proper maintenance and care are essential. Some of the maintenance tips include:

Control the temperature:

Keep the temperature of the hydraulic fluid within the recommended range by using a reservoir or a heat exchanger to dissipate heat. Excessive or low temperatures can affect the viscosity, lubrication ability, stability, and compressibility of the fluid.

Keep systems clean:

Prevent contaminants such as dirt, water, metal particles, or air from entering or accumulating in the system by using filters, seals, breathers, etc. Contaminants can cause wear, corrosion, leakage, or malfunction of the system components.

Choose the correct die sets:

Select die sets that are compatible with the fitting and hose sizes that you intend to use, as mismatched sizes can result in improper crimping, leakage, or failure.

Check the crimping force and accuracy:

Verify the functionality and accuracy of the crimping tool by using a gauge, a micrometer, or a caliper to measure the crimping force, pressure, speed, and diameter. Adjust the settings if necessary to ensure that they match the specifications of the terminal manufacturer.

Replace worn or damaged parts:

Inspect the system components for any signs of wear or damage, such as cracks, dents, scratches, or leaks. Replace or repair any faulty parts as soon as possible to prevent further deterioration or failure.

Buy Online... Hydraulic Hose Crimping 4KVA /220-415V HP51 KAIDA

Die Sets and Tooling

Die sets and tooling are crucial components of a hydraulic hose crimping machine, responsible for shaping the hoses and connectors to create secure and leak-free connections. Understanding their role and customization options is essential for achieving quality hose crimps.

Understanding Die Sets and Their Significance

Die sets are the heart of a crimping machine. They consist of two matching parts, the inner and outer die, that enclose the hose and fitting. When hydraulic pressure is applied, the dies compress the hose and fitting, creating a secure connection. These dies are designed to match specific hose and fitting dimensions to ensure a precise and consistent crimp. The quality and precision of die sets directly impact the integrity of the crimped connection.

Customizing Die Sets for Different Hose Sizes

One of the key advantages of hydraulic hose crimping machines is their adaptability to a wide range of hose sizes and types. Die sets can be easily replaced or customized to accommodate different hose diameters and connector designs. This flexibility is essential for industries dealing with various hoses, connectors, and fittings, as it allows one machine to handle diverse crimping tasks.

Quality Control and Precision

Achieving precision and maintaining quality control in crimping is dependent on the die sets and tooling. Proper die maintenance, calibration, and regular inspections are essential to ensure that the crimped connections meet the required standards. Precise die sets not only contribute to the mechanical strength of the crimp but also minimize the risk of leaks or other connection failures.

Understanding the role and customization options of die sets and tooling is paramount in achieving consistent, high-quality crimps. It ensures that hoses in hydraulic systems maintain their structural integrity and prevent leakage, supporting the overall efficiency and safety of hydraulic operations.

Buy Online... Hydraulic Hose crimping machine YMC 10Lc

Control Panel and Safety Measures

The control panel and safety measures of a hydraulic hose crimping machine play a crucial role in ensuring safe and efficient operation. Understanding these aspects is vital for both the machine's users and the integrity of the hose crimps.

Exploring the Machine's Control Panel:

The control panel is the nerve center of a hydraulic hose crimping machine. It allows operators to set and adjust various parameters, including crimping pressure, time, and cycle count. Different machines may have varying control panel interfaces, which can range from simple manual controls to more advanced digital displays and programmable logic controllers (PLCs). Learning how to navigate and utilize the control panel is essential for achieving the desired crimping results.

Safety Features and Interlocks:

Hydraulic hose crimping machines are equipped with numerous safety features to protect users from potential hazards. These safety measures can include emergency stop buttons, two-hand operation requirements, interlocking mechanisms that prevent accidental machine activation, and guards to shield operators from moving parts during the crimping process.

Emergency Shutdown Procedures:

In the event of an unexpected situation or safety concern, operators must be familiar with the emergency shutdown procedures for the machine. Emergency shutdown procedures may vary depending on the type and model of the machine, but they generally include the following steps:

- Press the emergency stop button on the control panel or in the field to stop the crimping operation and release the hydraulic pressure.

- Turn off the main power switch on the machine or disconnect it from the power outlet.

- Close the main valve on the hydraulic pump or reservoir to cut off the hydraulic fluid supply.

- Open the bleed valve on the crimping head to drain any residual hydraulic fluid from the system.

- Remove any hoses or fittings from the machine and store them in a safe place.

- Notify the supervisor or maintenance personnel of the emergency situation and follow their instructions.

Related Article;

The Ultimate Guide to Choosing the Right Hose Crimping Machine

Making my own network cable using electrical crimping tools

Frequently Asked Questions

Q1 What is a hydraulic crimping machine?

A hydraulic crimping hose machine is primarily used for connecting to the end of a variety of hose sizes and fabricating hose assemblies. The hose is connected by crimping one or both ends to ensure that the two portions are held together.

Q2 How do hydraulic mechanisms work?

In order to generate fluid power, hydraulic systems require a pump to force hydraulic fluid through the system. After going through the valves, the fluid enters the cylinder, where it transforms from hydraulic energy into mechanical energy. The valves assist in controlling the liquid's flow and releasing pressure when necessary.

Q3 What are the defects of crimping?

Corrosion, sporadic or subpar connection performance, and even total connection failure might result from using crimps of low quality. A terminated wire needs to meet a number of requirements in order to pass quality control.

Buy Online... Hydraulic Hose crimping machine PM20

Conclusion

To sum up, hydraulic hose crimping machines are essential for creating secure and leak-free connections between hydraulic hoses and fittings, which are vital for the integrity and safety of hydraulic systems. This article has explained the basics of hydraulic hose crimping, including the importance, components, process, system, die sets, safety measures, and emergency shutdown procedures. By understanding these aspects, you can appreciate the role of precision and safety in hydraulic hose crimping, which is a crucial practice that supports various industries and applications. Hydraulic hose crimping is not just a preference; it’s a necessity for a smoothly functioning hydraulic systems.

At GZ Supplies, we pride ourselves in the quality of our workshop machinery. Whether you are looking for fixed machinery or a more portable alternative, you can find the perfect equipment from amongst our vast range of products.