Eco-Friendly Industrial Chemicals: The Future of Sustainability in Manufacturing

In the face of escalating environmental concerns, sustainability in the use of industrial chemicals for manufacturing has transitioned from a nice-to-have to a must-have strategy. The industrial sector, known for its substantial environmental footprint, faces intense pressure to reduce waste, manage chemical emissions, and conserve resources. Embracing eco-friendly practices, particularly in chemical use, not only helps protect the environment but also aligns manufacturers with global sustainability goals and improves their competitive edge in the market.

Dr Fixit 604 Primeseal 10 Litre: The go-to primer to protect your plastered walls and concrete surfaces.

Dr Fixit 604 Primeseal 10 Litre: The go-to primer to protect your plastered walls and concrete surfaces.

Eco-friendly industrial chemicals are defined as substances used in manufacturing processes that have a reduced environmental impact compared to their conventional counterparts. These chemicals are biodegradable, derived from renewable resources, and manufactured through processes that minimize pollution and energy consumption. Unlike traditional industrial chemicals that often contain harmful toxins and persist in the environment, eco-friendly alternatives offer a safer, more sustainable solution to industrial needs.

Drivers for the Shift Towards Eco-Friendly Chemicals

1. Regulatory Pressures

Globally, governments are tightening environmental regulations that dictate the use of chemicals in manufacturing, compelling companies to rethink their chemical strategies. In the EU, regulations such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) enforce strict guidelines on chemical use, pushing manufacturers towards safer, more environmentally friendly chemicals. Similar initiatives are gaining momentum in other parts of the world, including Nigeria, where environmental awareness and legislation are gradually taking center stage.

2. Market Demand

Consumer awareness and demand for sustainable products are reshaping the market landscape. Modern consumers are more informed and concerned about the environmental impact of their purchases, driving demand for products made with eco-friendly chemicals. Additionally, B2B clients are increasingly stipulating sustainability criteria in their procurement processes, requiring suppliers to demonstrate commitment to environmentally responsible manufacturing practices.

3. Technological Advancements

Technological innovations have made the production and application of eco-friendly chemicals more viable than ever before. Advances in green chemistry are leading to the development of chemicals that are as effective as traditional ones but with a fraction of the environmental impact. These technologies not only help in creating new eco-friendly chemical formulations but also enhance the efficiency of chemical processes, reducing waste and energy use.

Benefits of Eco-Friendly Industrial Chemicals

1. Environmental Benefits

The adoption of eco-friendly industrial chemicals significantly reduces the environmental impact of manufacturing processes. These chemicals typically feature lower toxicity levels, which minimizes pollution and improves air and water quality. Additionally, because many eco-friendly chemicals are biodegradable, they break down more easily in the environment, reducing long-term pollution and helping to preserve natural ecosystems.

2. Economic Benefits

Switching to eco-friendly chemicals can also offer substantial economic advantages to manufacturers. While the initial cost might be higher, the long-term savings are considerable. These come from reduced waste management costs, lower water and air purification costs, and compliance with regulatory standards that might otherwise result in fines or sanctions. Furthermore, using sustainable practices can open up new markets, attract eco-conscious customers, and increase competitiveness.

3. Social Benefits

The use of eco-friendly chemicals improves workplace safety by reducing exposure to toxic substances, thereby enhancing employee health and reducing the risk of chemical-related illnesses and accidents. This can lead to lower healthcare costs and less downtime due to worker sickness. Moreover, companies that are known for their commitment to sustainability often enjoy a more positive public image, which can enhance brand loyalty and community support.

Dr Fixit Polyplus CP: Lock out leaks with the ultimate defense against water, for concrete.

Dr Fixit Polyplus CP: Lock out leaks with the ultimate defense against water, for concrete.

Challenges in Adoption

1. High Initial Costs

The transition to eco-friendly chemicals often involves high upfront costs. These can include expenses related to the procurement of new materials, changes in production processes, and training for staff. However, these initial investments are frequently offset by the long-term savings and benefits discussed earlier.

2. Technological Barriers

While technological advances have facilitated the use of eco-friendly chemicals, significant barriers still exist, particularly in integrating these new chemicals into existing manufacturing systems without compromising product quality or process efficiency. Furthermore, in regions with limited technological advancement, accessing these innovations can be particularly challenging.

3. Lack of Awareness and Education

A significant hurdle in the adoption of eco-friendly industrial chemicals is the lack of awareness and understanding among stakeholders, from management to the factory floor. Misconceptions about the effectiveness and cost of eco-friendly chemicals can hinder their adoption. Effective educational campaigns and transparent communication are critical in overcoming these challenges.

Case Studies

Success Stories

One notable example Epoxy Oilserv Nigeria Limited, Water plant manufacturer in Nigeria that switched to using eco-friendly water treatment chemicals and processes. This shift not only resulted in a 40% reduction in their environmental waste but also enhanced their compliance with international export standards, leading to an expanded global market presence.

Future Trends and Predictions

1. Emerging Chemical Innovations

The future of manufacturing is poised to be significantly shaped by ongoing innovations in eco-friendly chemicals. Researchers are developing novel bio-based solvents and catalysts that promise to reduce harmful emissions and energy consumption even further. Moreover, the integration of nanotechnology is expected to enhance the efficiency and specificity of chemical reactions in manufacturing, minimizing waste products and improving the quality of the final goods.

2. Policy and Market Shifts

As global awareness of environmental issues increases, regulatory bodies are likely to impose stricter sustainability requirements. This regulatory shift, coupled with a growing consumer preference for sustainable products, is expected to drive substantial market growth in the eco-friendly sector. Manufacturers who anticipate and adapt to these changes will not only mitigate risks associated with compliance but also capitalize on the expanding market for green products.

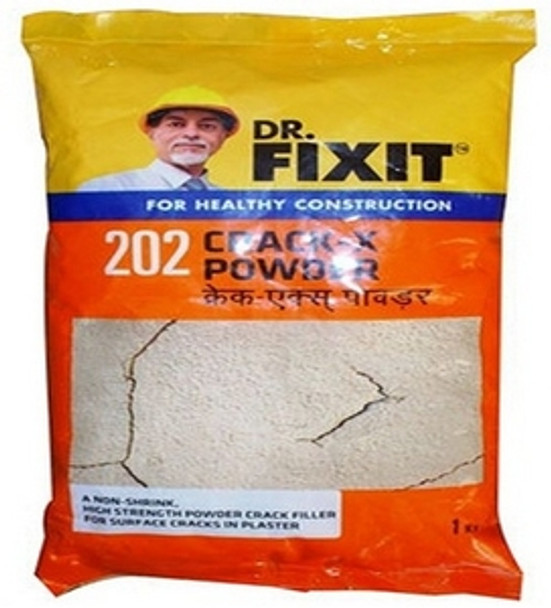

Dr. Fixit 202 Crack-X Powder: The ultimate crack-filler for a seamless and perfect finish.

Dr. Fixit 202 Crack-X Powder: The ultimate crack-filler for a seamless and perfect finish.

Strategies for Manufacturers

1. Implementing Eco-Friendly Practices

For manufacturers looking to transition to eco-friendly chemicals, the first step is conducting a comprehensive audit of current chemical usage and its environmental impact. Following this, manufacturers should explore alternative eco-friendly options that meet their specific needs. It is also crucial to engage with stakeholders, including suppliers and customers, to align expectations and foster collaborative efforts towards sustainability.

2. Leveraging Technology and Partnerships

Adopting new technologies that facilitate the use of eco-friendly chemicals can significantly enhance a manufacturer's sustainability profile. Collaborating with industry leaders and academic institutions for R&D can also accelerate the development and integration of innovative solutions. Additionally, partnerships with certification bodies can help validate the environmental benefits of new practices, enhancing credibility and consumer trust.

Frequently Asked Questions

1. What are the most common eco-friendly chemicals used in manufacturing today?

Common eco-friendly chemicals include bio-based solvents, organic acids, and recycled polymers, all of which provide sustainable alternatives to their synthetic counterparts.

2. How can manufacturers measure the impact of switching to eco-friendly chemicals?

Impact can be measured through reductions in carbon emissions, waste production, and energy usage, as well as improvements in worker safety and health outcomes.

3. Are eco-friendly chemicals as effective as traditional chemicals?

Yes, with advances in green chemistry, eco-friendly chemicals can be just as effective, if not more so, depending on the application. They are specifically formulated to provide the same functionality while reducing environmental impact.

4. What incentives are available for manufacturers adopting eco-friendly chemicals?

Incentives include tax breaks, subsidies, and grants from government bodies, as well as potential cost savings from improved efficiency and waste reduction.

5. Where can manufacturers find suppliers of eco-friendly chemicals?

Manufacturers can find suppliers through industry trade shows, green directories, and platforms that specialize in sustainable supply chain resources, such as GZ Industrial Supplies.

Dr. Fixit 302 Super Latex: The Bond That Never Breaks - 20Kg of superior adhesion, for repairs that last a lifetime.

Dr. Fixit 302 Super Latex: The Bond That Never Breaks - 20Kg of superior adhesion, for repairs that last a lifetime.

Conclusion

The shift towards eco-friendly chemicals is not just a trend but a fundamental change that is reshaping the manufacturing landscape. Companies that proactively integrate these practices are poised to lead the market in the coming years, achieving not only environmental and regulatory compliance but also securing a competitive edge.

This guide has highlighted the crucial role that eco-friendly industrial chemicals play in advancing sustainability within the manufacturing sector. By embracing these innovations, manufacturers can significantly reduce their environmental footprint, enhance operational efficiency, and improve social goodwill.

For a comprehensive selection of eco-friendly industrial chemicals and expert guidance on sustainable manufacturing practices, visit GZ Industrial Supplies. Equip your operations with the tools needed to thrive in the future of sustainable manufacturing. Explore our resources and take proactive steps towards a greener industrial environment today.

Recent Posts

-

The Ultimate Guide to welding and fabrication services in Nigeria

Welding and fabrication plays a vital role in Nigeria's economic development. These services are fun …Apr 30, 2024 -

Understanding Metal Properties and Their Impact on Welding Success

Specific Metal Characteristics Matter: Each metal's unique properties such as thermal conductivity …Apr 30, 2024 -

Dongcheng Rotary Hammer: A Comprehensive Guide for Contractors

Key takeaway;The DongCheng Rotary Hammer serves as an invaluable resource for contractors seeking to …Apr 26, 2024