Hydraulic Power Packs System Design and Maintenance

Proper system design and regular hydraulics maintenance are crucial for ensuring hydraulic power packs' efficient and reliable operation. By paying attention to these aspects, industries can optimize performance, extend the lifespan of their equipment, and minimize costly downtime. Let's explore the importance of system design and maintenance in detail.

Design Considerations

When designing a hydraulic power pack system, several factors should be considered. These include application requirements, energy efficiency, environmental sustainability, and overall design capability. The system must handle the demands of different applications, whether for a large-scale operation or a smaller engineering project. A well-designed system considers the dynamic world of hydraulic systems and provides the necessary power, control, and safety features. Designers must also consider the size and pressure capability of the components, such as the hydraulic pumps, motors, and cylinders, to ensure they can handle the required workload.

Standard Manual Hydraulic Stacker

Maintenance Practices

Regular maintenance is essential to keep hydraulic power packs operating at peak performance. Maintaining the system involves various tasks that help identify and prevent potential issues.

Routine maintenance tasks include monitoring fluid levels, checking for leaks, inspecting filters and valves, and ensuring the proper functioning of all components. Regular fluid analysis should also be conducted to assess the cleanliness and condition of the hydraulic fluid. By adhering to a comprehensive maintenance schedule, industries can detect and resolve problems before they escalate, preventing costly breakdowns.

Troubleshooting Common Issues

Despite proper design and maintenance, hydraulic power packs can still encounter issues. Common problems include fluid contamination, system overheating, component wear, and poor performance.

To address these issues, it's important to have a troubleshooting strategy in place. This includes identifying the root cause of the problem, inspecting affected components, and making the necessary repairs. Collaborating with experienced hydraulic technicians or seeking guidance from the power pack manufacturer can expedite the troubleshooting process and ensure proper resolution.

Professional Hydraulic Power Pack Suppliers

Working with reliable and reputable hydraulic power pack suppliers is critical in obtaining high-quality systems and components. Suppliers with years of hydraulic engineering experience have in-depth knowledge of the intricate world of hydraulic systems. They can provide expertise in system design, offer customized solutions, and recommend the most suitable power pack for specific applications.

Tend Industrial Supplies and its Torstarc Hydraulic and Bolting brand are trusted hydraulic power pack suppliers offering various options and designs. From custom power units to standard designs, they cater to diverse industries such as automotive, agriculture, fishing, and more. Collaborating with a reputable supplier ensures access to quality products and reliable customer support throughout the system's lifespan.

In conclusion, proper system design and regular maintenance are essential for maximizing the performance and longevity of hydraulic power packs. By considering design factors, conducting routine maintenance, and troubleshooting common issues, industries can ensure optimal operation and minimize costly downtime. Collaborating with reliable suppliers and seeking professional expertise further enhances system reliability and efficiency.

Hydraulic Hose Crimping 4KVA /220-415V HP51 KAIDA

Design Considerations

When designing a hydraulic power pack system, several factors should be carefully considered to ensure optimal performance and efficiency. Here are some key design considerations to keep in mind:

1. Operating Conditions:

Take into account the specific application requirements, including the desired pressure capability, flow rate, and temperature range. Understanding the operating conditions is crucial for selecting the right components and determining the appropriate size and capacity of the power pack.

2. Component Selection:

Choose reliable and high-quality components such as hydraulic pumps, motors, valves, and regulators. Consider factors such as compatibility, durability, and efficiency to ensure long-term functionality and performance.

3. System Layout:

Plan the layout of the power pack system to optimize space utilization and accessibility for maintenance. Proper arrangement of components, such as the reservoir, pump, motor, and control valves, can enhance efficiency and ease of operation.

4. Energy Efficiency:

Efficient energy consumption is essential for minimizing costs and promoting environmental sustainability. Select components and systems that are designed for energy efficiency to reduce power loss and overall energy consumption.

LubeMax Hydraulic Oil ISO 46

5. Environmental Considerations:

Consider environmental factors such as temperature variations, humidity levels, and possible exposure to contaminants. Use appropriate materials and protective measures to ensure reliable performance under challenging conditions.

6. Safety Measures:

Incorporate safety features and designs to protect both operators and the equipment. This may include pressure relief valves, emergency stop buttons, and proper shielding to prevent accidents and damage.

7. Maintenance Accessibility:

Design the power pack system with ease of maintenance in mind. Ensure that key components can be easily accessed and serviced, allowing for regular inspections, repairs, and replacements as needed.

8. Future Expansion:

Anticipate potential future needs or expansion of the hydraulic system. Leave room for additional components or upgrades to accommodate future requirements without significant redesign or system overhaul.

By considering these design factors, you can create a hydraulic power pack system that meets the specific application demands and ensures reliable performance, energy efficiency, and ease of maintenance. Consulting with experienced hydraulic engineers or working with reputable suppliers can provide valuable insights and guidance in designing an optimized system.

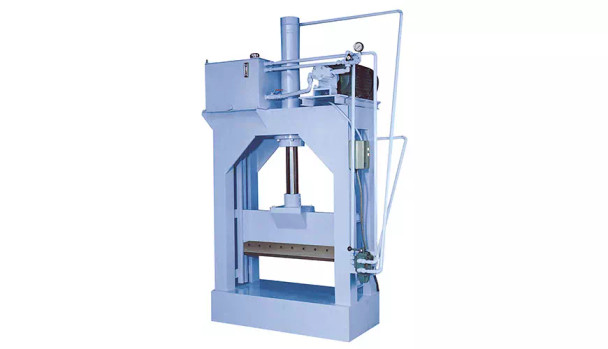

Hydraulic presser HP005 Hellog

Maintenance Practices of Hydraulic power packs

Regular maintenance is essential for ensuring hydraulic power packs' efficient operation and longevity. By following these maintenance practices, you can maximize the performance of your hydraulic system:

1. Fluid Inspection: Regularly check the hydraulic fluid levels to ensure they are at the correct viscosity and contamination-free.

2. Filter Replacement: Replace the filters at recommended intervals to prevent debris from entering the system and causing damage.

3. Seal Inspection: Check the seals for any signs of wear or leaks and replace them if necessary.

4. Pressure Checks: Monitor the system's pressure settings to ensure they are within the recommended range.

5. Component Lubrication: Apply lubricants to components that require it, such as hydraulic pumps and motors.

6. System Flushing: Periodically flush the system to remove any built-up contaminants and ensure optimal performance.

Adhering to these maintenance practices can enhance the reliability and lifespan of your hydraulic power pack, reducing the risk of costly downtime and repairs. Regular maintenance also improves overall system efficiency and minimizes the risk of performance degradation over time.

Troubleshooting Common Issues of Hydraulic Power Packs

For hydraulic power pack systems, encountering issues is inevitable. However, identifying and resolving these common problems is crucial for optimal performance. Here are some helpful tips to troubleshoot common problems in hydraulic power pack systems:

1. Leakages: Inspect all hydraulic connections and replace any damaged or worn-out seals or hoses.

2. Overheating: Check the hydraulic fluid level and quality, ensuring it matches the manufacturer's recommendations. Also, ensure proper cooling mechanisms are in place.

3. Inconsistent Pressure: Verify if the hydraulic pump is functioning correctly and make adjustments to pressure regulators if necessary.

4. Unusual Noises: Listen for any strange noises and consult the manufacturer's guidelines to pinpoint the source, which could involve air ingestion or worn-out components.

Remember, regular maintenance and periodic checks are crucial to prevent issues and ensure the longevity of your hydraulic power pack system.

NC1924, Hydraulic Nut Cutter, Hexagon ENERPAC

Professional Hydraulic Power Pack Suppliers

When it comes to hydraulic power pack systems, choosing the right supplier is crucial for ensuring reliable and efficient operation. Working with professional hydraulic power pack suppliers can offer several advantages for industrial operations.

Superior Product Quality

Professional suppliers have a reputation for delivering high-quality hydraulic power packs. They source components from trusted manufacturers and adhere to strict quality control standards. This ensures that the power packs are durable, reliable, and capable of handling heavy loads and high-pressure requirements.

Extensive Expertise

These suppliers have years of experience in the hydraulic industry and possess in-depth knowledge of different applications and requirements. They can provide valuable insights and guidance in selecting the most suitable power pack for specific applications, taking into account factors such as energy efficiency, environmental sustainability, and design capabilities.

Customization Options

Professional suppliers understand that each application may have unique demands. They offer custom hydraulic power pack solutions tailored to meet specific requirements. Whether it's for a large-scale engineering project, a mobile application, or a specialized industry like agriculture or automotive, they can design and manufacture power packs that precisely match the desired parameters.

Proven Track Record

Choosing a reputable supplier means having peace of mind that they have a track record of delivering reliable hydraulic power pack solutions. They have satisfied customers across various industries and can provide references or case studies to demonstrate their expertise and commitment to customer satisfaction.

Collaborating with professional hydraulic power pack suppliers ensures access to superior product quality, extensive industry expertise, customization options, and a proven track record. Conduct thorough research and choose a supplier that aligns with your needs, ensuring smooth and efficient hydraulic system operation.

Hydraulic cutting machine CV450 Kaida

Conclusion

In conclusion, hydraulic power packs are vital components in various industries and are crucial in ensuring efficient operation and productivity. Throughout this article, we have explored the typical applications, working principles, and the significance of proper system design and maintenance for hydraulic power packs. Hydraulic power packs find extensive use in hydraulic presses, where their exceptional power capability and precise control enable effective material shaping and forming processes. They are also essential in plastic injection molding machines, facilitating the accurate and efficient injection of molten plastic into molds.

Hydraulic excavators' functionality heavily relies on hydraulic power packs, which provide the necessary power for movement, lifting, and digging operations. Hydraulic power packs are also essential in drilling rigs, ensuring reliable and efficient drilling performance in various industries.

Understanding the key components of hydraulic power packs is crucial. The hydraulic reservoir serves as a storage and cooling system for hydraulic fluid, while the hydraulic pump generates the necessary hydraulic pressure. Hydraulic motors convert hydraulic power into mechanical energy, enabling the movement of machinery. Regulators and relief valves play a role in maintaining system stability and preventing excessive pressure.

Proper system design and regular maintenance are essential for hydraulic power packs' optimal performance and longevity. Design considerations include the specific application, energy efficiency, and environmental sustainability. Regular maintenance practices and troubleshooting common issues are essential to ensure smooth operation and prevent costly breakdowns. Working with reliable and reputable sources is crucial when seeking hydraulic power pack suppliers. Reputable suppliers offer quality products and exceptional customer support, ensuring your hydraulic power packs meet your specific requirements. Contact us at GZ Industrial Supplies for questions regarding the supply of hydraulic power packs.

Recent Posts

-

Comparing Different Coating Techniques: Pros and Cons

Coating techniques play a vital role in the longevity and functionality of products and structures b …May 06, 2024 -

The Ultimate Guide to Coating Painting Services: Everything You Need to Know

Coating painting services have become increasingly popular in recent years due to their ability to e …May 03, 2024 -

Choosing the Right Welding Services for Your Construction Project in Nigeria

Selecting the right welding services involves evaluating their capability to handle the specific req …May 03, 2024