What are Construction Chemicals ?

Key takeaway

Introduction

Construction chemicals have always been playing important roles in virtually all sorts of construction projects, be it industrial projects, residential building projects, commercial building projects and so on. These chemicals are often used in various elements of projects in order to achieve various important qualities such as workability, durability etc. Construction chemicals exist in many varieties from a large number of manufacturers worldwide.

Construction chemicals are chemical formulations used with masonry materials, cement, concrete or other construction materials at the time of construction to hold the construction materials together.

Available for Pickup... Dr. Fixit 302 Super Latex 20Kg

How construction chemicals affect the construction process and their Uses

Most construction chemicals are used as hardening agents either for surface application, coating or as repair materials and is also effective as a waterproofing chemical. Here below are different types of construction chemical.

Dr Fixit Raincoat 601 20L

1. Concrete Hardeners

These are chemicals added in floor concrete in order to render it denser and more durable. They also usually enhance chemical resistance, impact & abrasion resistance, waterproofing capability etc. besides reducing dusting. All these are required attributes especially for industrial, commercial or factory floors. Ultimately good quality floor hardeners reduce repairs and maintenance of concrete floors drastically besides making them long lasting thus adding to cost effectiveness as well. Floor hardeners can be liquid or solid, metallic or non metallic. Metallic floor hardeners (solid) are well graded ferrous aggregates. Liquid floor hardeners are water, silicate etc. based solutions. Pigmented floor hardeners also improve the appearance of floor surfaces. Floor hardeners are usually applied as per manufacturer’s specifications This construction chemical Improves the abrasion resistance of dusty or poorly cured concrete by up to 3 times. Has good resistance to alkali solution and petroleum solvents but poor resistance to strong acids.

2. Protective and Decorative coating

A protective coating is a layer of material applied to the surface of another material with the intent of inhibiting or preventing corrosion. A protective coating may be metallic or non-metallic. Protective coatings are applied using a variety of methods, and can be used for many other purposes besides corrosion prevention. Commonly used materials in non-metallic protective coatings include polymers, epoxies and polyurethanes. Materials used for metallic protective coatings include zinc, aluminum and chromium. Special materials are used in the finishing coats of plastering or over the plastered surfaces to meet one or more of specific requirements such as decorative appearance, high durability, fire – proofing, heat insulation, sound insulation, early completion, high strength etc.

3. Concrete Curing

Concrete curing compound consists essentially of waxes, natural and synthetic resins, and solvents of high volatility at atmospheric temperatures. The compound forms a moisture retentive film shortly after being applied on a fresh concrete surface. White or gray pigments are often incorporated to provide heat reflectance, and to make the compound visible on the structure for inspection purposes. Curing compound should not be used on surfaces that are to receive additional concrete, paint, or tile which require a positive bond, unless it has been demonstrated that the membrane can be satisfactorily removed before the subsequent application is made, or that the membrane can serve satisfactorily as a base for the later application.

Epoxy Resin Epochem 105, 5kg

4. Epoxy Coating

These can come as water or oil based solutions or as solvent-free. They can be single or two-component. Single-component epoxy paints are usually oil based. Two-component epoxy coatings are mixed in situ in proportions as prescribed by their manufacturers and they are quite suitable for factory, industrial or commercial building applications by dint of their excellent chemical & thermal resistant characteristics, hardness, durability, waterproofing characteristics etc. They are solvent-free. Epoxy coatings are also used in flooring for decorative purposes.

5. Mould Releasing Agents

Mould release agents come in handy when you have materials that are shaped and constructed in moulds. Without the releasing agent, your mould may become damaged or even break when it is time to remove it. Mould release agents come in a variety of textures with the most commonly used one being an oil type base. If you have never used a releasing agent before, it is similar to placing oil or butter in the bottom of a dish to remove your final baking product. Below, you will find the three most commonly used types and their purpose in the manufacturing industry.

6. Polymer Bonding Agent

Polymer Bonding Agent is an aqueous emulsion of a polymer and chemical admixtures. It is designed for use as a bonding agent with concrete and cement-based products in interior or exterior applications. Polymer Bonding Agent is also designed for use as a polymer modifier in mortars and concretes to develop increased tensile, flexural and bond strengths. The use of Polymer Bonding Agent in concrete and shotcrete also gives significant improvements in resistance to penetration by chlorides and de-icing salts.

Dr. Fixit Construction Foam 1 Carton

7. Ready Mix Plaster

Ready mix plaster is a factory mixed/premixed sand-cement based plaster. All the activities that are generally undertaken on-site are performed in a quality-controlled environment at the plant to ensure no-batch variation and optimum sand gradation, which is of utmost importance for any plaster. Other additives such as fly ash and polymers are also added to it, to improve its performance and various other properties. These are generally used for building houses or making solid structures of any sort. Apart from these, they can also be used for various other purposes that require you to put two or more things together that will hold strong for long. You can also use ready mix plaster to make models.

8. Polymer Modified Mortar

Polymer-modified mortar is made by replacing a portion of the traditional binders with polymers. Polymers are added to mortar to increase characteristics that may include adhesion, toughness, flexural or tensile strength, and resistance to chemicals. Polymers act to improve the workability and adhesion of non-hardened mortar and often require less added water than does traditional mortar, which results in fewer pores and stronger cements, subsequently reducing water ingress and permeability to salts. Polymer-modified mortar is often commercially available with all ingredients already included in the mixture.

9. Waterproofing Chemicals

These chemicals can be quite useful when a structure’s waterproofing capability is to be given a boost which is especially required for structures constantly dealing with liquids. There are many varieties. Some of them are crystalline waterproofing chemicals, liquid acrylic elastomeric waterproofing compounds, polymer modified waterproofing compounds, cementitious waterproofing compounds etc. Many of these compounds form membranes on the concrete surfaces to protect them from ingress of water.

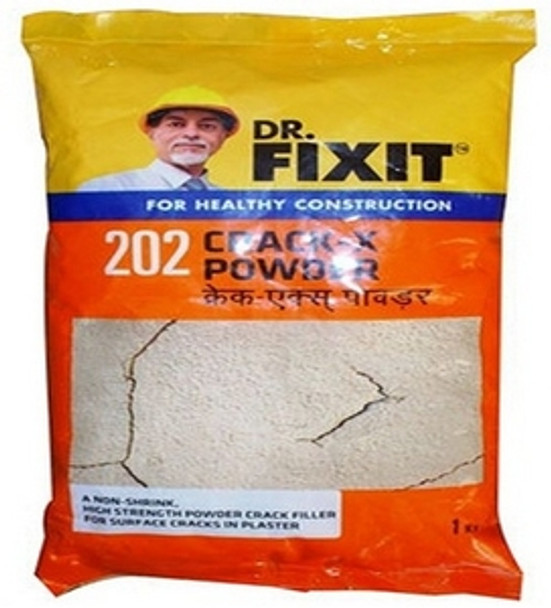

Dr. Fixit 202 Crack-X Powder

There are other types and uses of construction chemicals, but these ones are more prevailing. GZ Industrial Supplies prides in the distribution and services of construction chemicals, contact us for more information.

How to Choose the Right Construction Chemical for a Particular Project

Choosing the right construction chemical for a project is crucial for ensuring durability, safety, and effectiveness. Here’s a step-by-step guide to help you make an informed decision:

1. Understand the Project Requirements

- Assess the Project Scope: Determine the scale and nature of the project. Is it residential, commercial, or industrial?

- Identify the Specific Needs: What are the primary requirements? Waterproofing, strengthening, bonding, or protection against environmental factors?

2. Evaluate the Environmental Conditions

- Climate Considerations: Consider the local climate conditions, such as humidity, temperature variations, and exposure to chemicals or pollutants.

- Substrate Compatibility: Ensure the chemical is compatible with the materials being used, like concrete, steel, or wood.

3. Determine the Desired Properties

- Strength and Durability: Choose chemicals that enhance the structural integrity and longevity of the construction.

- Setting Time: Consider the required setting time based on project deadlines.

- Chemical Resistance: Ensure the chosen product can withstand exposure to harsh chemicals if applicable.

4. Research Product Options

- Manufacturer Reputation: Opt for products from reputable manufacturers known for quality and reliability.

- Technical Specifications: Review the technical datasheets to understand the chemical composition and performance characteristics.

5. Consult with Experts

- Professional Advice: Seek guidance from civil engineers, architects, or construction chemical experts to ensure you select the right product.

- Case Studies and Testimonials: Look for case studies or testimonials of similar projects to see what products were successfully used.

6. Cost-Benefit Analysis

- Budget Considerations: Balance between cost and quality. Sometimes, investing in a more expensive product can save money in the long run by reducing maintenance costs.

- Longevity and Maintenance: Consider the long-term benefits and maintenance requirements of the chemical.

Safety Precautions Necessary When Using Construction Chemicals

Using construction chemicals safely is paramount to protect workers and ensure the effectiveness of the chemicals. Here are essential safety precautions:

1. Personal Protective Equipment (PPE)

- Wear Appropriate Gear: Always wear gloves, safety goggles, masks, and protective clothing to prevent direct contact with chemicals.

- Use Respiratory Protection: When dealing with volatile or dusty chemicals, use respirators to avoid inhaling harmful substances.

2. Proper Handling and Storage

- Read Labels and Datasheets: Always read and follow the manufacturer's instructions and safety data sheets (SDS) for proper handling and usage.

- Secure Storage: Store chemicals in a cool, dry place away from direct sunlight and incompatible substances. Ensure containers are tightly sealed.

3. Ventilation

- Ensure Adequate Ventilation: Work in well-ventilated areas to avoid the buildup of fumes. Use exhaust fans or open windows to increase airflow.

- Avoid Confined Spaces: Minimize the use of chemicals in confined spaces without proper ventilation.

4. Safe Mixing and Application

- Use Proper Tools: Utilize appropriate tools and equipment for mixing and applying chemicals to avoid spills and splashes.

- Follow Mixing Instructions: Adhere to the recommended ratios and mixing procedures to ensure the chemical's effectiveness and safety.

5. Emergency Preparedness

- First Aid Kits: Keep first aid kits readily available on-site, along with instructions for treating chemical exposure.

- Emergency Contacts: Have emergency contact numbers and procedures posted clearly in case of accidents or spills.

6. Training and Awareness

- Educate Workers: Provide regular training on the safe use, handling, and storage of construction chemicals.

- Safety Meetings: Conduct safety meetings to review procedures and reinforce the importance of using PPE and following safety protocols.

7. Disposal of Chemicals

- Follow Regulations: Dispose of chemical waste according to local regulations and guidelines to avoid environmental contamination.

- Use Designated Containers: Utilize designated containers for chemical waste and ensure they are clearly labeled.

By following these guidelines, you can select the right construction chemicals for your project and ensure their safe and effective use. Prioritizing safety not only protects workers but also ensures the longevity and success of the construction project.

Conclusion

Construction chemicals play a crucial role in modern construction projects, enhancing the performance, durability, and aesthetics of structures. These specialized products are essential for various applications, including waterproofing, concrete admixtures, surface treatments, and protective coatings. By leveraging construction chemicals, builders and engineers can address specific challenges, improve the quality of construction, and extend the lifespan of buildings and infrastructure.

Contact us to learn more about Construction chemicals and how you can make a purchase.

Recent Posts

-

HOW TO RESOLVE WATER PUMP FAILURE

Water pumps are little heroes in our homes but are usually forgotten until we have a problem. As lon …Oct 21, 2024 -

Epoxy vs. Polyurethane Flooring: Which is Best for Your Space?

Key Takeaway Epoxy flooring is highly durable, chemical-resistant, and ideal for industrial and hig …Oct 18, 2024 -

Understanding Cable Types: Applications and Uses in Industry

Key Takeaway Different cable types serve various industrial applications, including power transmi …Oct 18, 2024