What is the best Industrial cleaner? Water-based cleaners or solvent cleaners?

What is the best Industrial cleaner? Water-based cleaners or solvent cleaners?

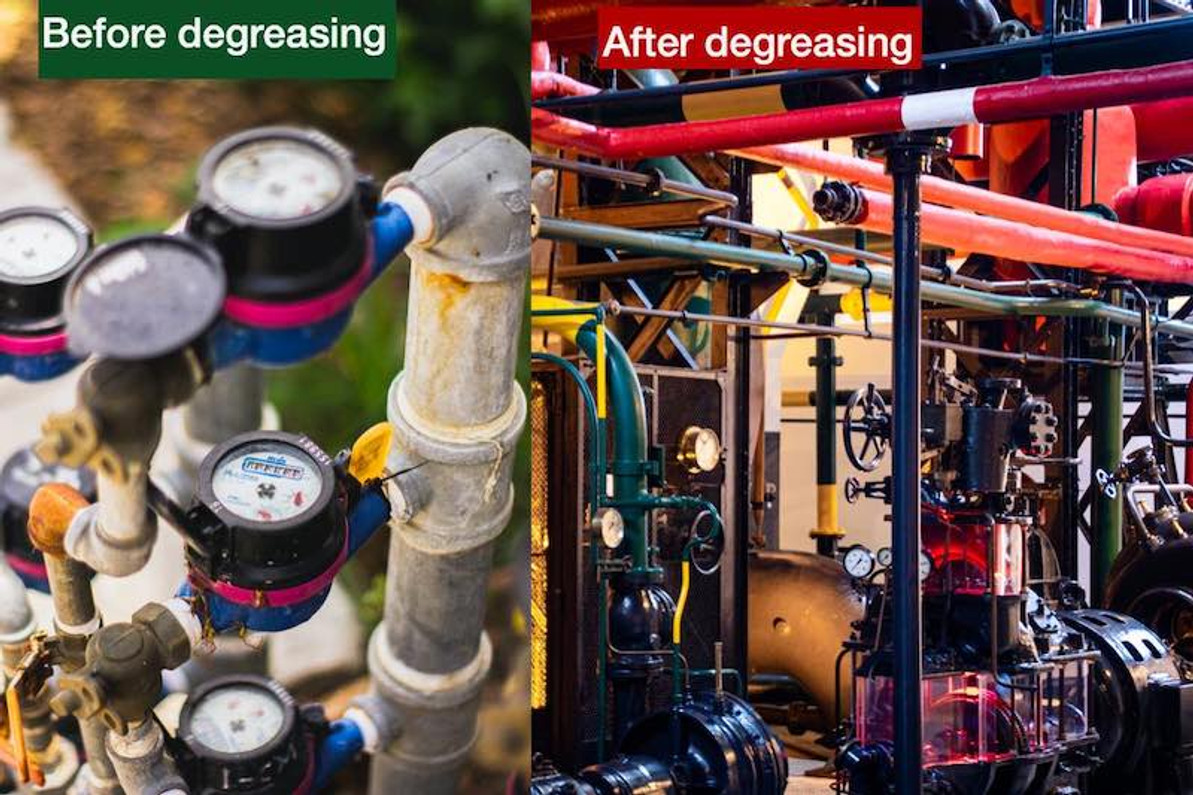

There is a growing popularity of water-based chemicals and new technologies; the reason underscores regulatory challenges and hurdles that the solvent cleaners will have to meet to get approvals. Companies with cleaning requirements such as industrial, precision, and specification-driven applications must decide which application they will have to use; what is the best application for their specific needs. This article is about the frequently asked question, "what is the best industrial cleaner? This article digs into if it is water-based cleaners or solvent cleaners?.

let us start by understanding and exploring their differences;

Why classify them as water-based cleaner or solvent cleaners?

For our discussion, a solvent cleaner or solvent degreaser uses a liquid to dissolve soil. It can utilize one solvent, a variety of solvents, or various solvents and compounds to maximize performance parameters for a specific application. Solvents is classified into their essential functional compounds, such as alcohols, ketones, aliphatic hydrocarbons, etc. Each chemical category has particular characteristics that lend to different solvency profiles, and the addition of other compounds and mixtures provides the range of solvency seen in commercial products. These different solvents and cleaning solutions can be tuned to remove a specific soil while leaving other materials relatively untouched. Some familiar solvents include acetone and butyl acetate, found in local hardware stores, alcohols such as isopropanol and ethanol, and even gasoline, a mixture of hydrocarbons.

Water is also a solvent and is a subsection of the solvent category. Water-based degreasers such as epochem 502 utilize water as the primary solvent. Still, they can also include any of the solvents mentioned above, plus detergents, pH modifiers, builders, chelating agents, and a variety of other compounds. When these other compounds are inclusive, Water-based cleaners can be powerful cleaners or mild, can be dangerous or relatively nontoxic, but usually require a rinse step. The variety and complexity of water-based cleaners are enormous. We can use the two degreasers in various ways, including degreasing, precision cleaning, ultrasonic cleaning, medical device assembly cleaning, and more.

SOLVENT CLEANERS

All solvents work by dissolving the soil, breaking it down into smaller particles, and carrying it into the solution and away from the cleaned surface. Many solvents offer an advantage of a quick cleaning, so the soils dissolve and flow off of the substrate without needing extended prep time, processing time, or drying time.

Solvent-based cleaners remain widespread in industrial applications due to their cleaning power; they remove thick, baked-on oils, dirt, containments, solder flux, and greases. Some examples of strong cleaning solvents are acetone, methyl ethyl ketone, toluene, nPB, and trichloroethylene (TCE). Common mild solvents include isopropyl alcohol, glycerin, and propylene glycol. In this case, the terms "strong" and "mild" are arbitrary designations. Solvent strength depends not only on the soils being removed but also on the amount of dirt to be removed and the required cleanliness level.

Solvent-based cleaners can be fast evaporating or slow evaporating, high in odor or low in odor, plastic safe, or very aggressive. The variety of solvents lends to creating particular cleaning chemistries for removing specific soils from substrates. Some cleaners are capable of firing a specific link on a plastic substrate while leaving others completely untouched.

FLAMMABLE SOLVENTS VERSUS NON-FLAMMABLE SOLVENTS

When choosing a solvent cleaner, one of the first questions is whether a flammable or non-flammable solution is preferable. Suppose volatile solvents can be safely used and there are no ignition sources. In that case, there is good air turnover and can follow all safety protocols. Flammable solvents tend to be much less expensive in general than non-flammable solvents. However, if any of the safety concerns are an issue, many non-flammable solvents are chosen.

EVAPORATION RATE OF SOLVENTS

Solvents evaporation rates are available that are immediate volatile, and others that only evaporate at elevated temperatures. Those that evaporate immediately may be better suited to minimizing process downtime, while those that evaporate much more slowly are better suited to high-temperature soak applications. There is not a single solvent that works for all applications. Those that evaporate more slowly are less likely to be VOC's but may need an additional drying process.

Understanding surface tension of Solvents.

Surface tension is a measurement of a liquid's ability to wet a surface or its ability to pull together into a cohesive droplet. The lower the surface tension of a material, the greater its ability to wet a surface and lay down a thin, even coat. When the surface tension is high, the liquid tends to pull together to form droplets. In general, solvents tend to offer lower surface tension than water-based cleaners, providing the ability to permeate into tight clearance areas to remove soils without being entrapped.

When dealing with chemicals, wear safety protections.

All solvents and cleaners, in general, should be handled while using personal protective equipment in well-ventilated areas to minimize exposure. Follow the recommendations offered by the manufacturer's SDS.

A growing concern with many solvents is whether they contain Volatile Organic Compounds or VOCs. VOC's are materials that readily evaporate and turn into the gaseous state at average room temperatures. VOC's ability to contribute to smog formation and the environmental and personal health impacts associated with them. No-VOC or low-VOC solvents are becoming such an important issue as companies use them to meet air quality standards to improve workers' safety.

Various tradeoffs can accompany the use of solvents that do not contain VOCs. One is the possible increase in the drying time of the cleaners. This is the case for both water-based and solvent-based systems. One way to decrease the VOC impact of a cleaner is to add slow evaporating solvents to the mixture that minimize the VOC contribution to the environment. This can be the addition of certain materials that act like oils or add water mixtures to the cleaner. In either case, additional processes, including rinsing, drying heat tunnels, or reclamation procedures, may be required to meet the required process parameters.

Another tradeoff can be the use of VOC exempt materials, such as acetone, siloxanes, and PCBTF. While these solvents are generally strong cleaners, they are flammable, and the acetone and PCBTF have high odor levels. Acetone is a relatively low cost, but the PCBTF and siloxanes are much more costly. Other VOC exempt materials, such as HFC-43-10mee, do not have sufficient cleaning ability to remove most soils when used by themselves and must be mixed with other stronger solvents to increase the cleaning ability.

Water-based cleaners

Water-based cleaners remove soils not only by dissolving contaminants, but they can also chemically react with the pollutants and make them more readily dissolvable in water. For example, some materials will react with or dissolve more readily into an acidic solution (pH of 7 or lower). We can find some common acidic materials in lemons (citric acid), vinegar (acetic acid), soft drinks (carbonic and phosphoric acid), and car batteries (sulfuric acid).

Other materials are more readily reacted with or dissolved into a solution with a pH above 7. These solutions are caustic or alkaline. Some common caustic materials are ammonia, bleach (sodium hypochlorite), lye (sodium hydroxide), and oven cleaners (more sodium hydroxide).

Most aqueous cleaners contain a variety of other components to enhance the cleaning profile. These other materials can include[2]:

- Detergents or surfactants; These are materials that have wetting and emulsifying properties and can carry soils into a solution that would not otherwise go.

- Builders; These are materials that increase the efficacy of detergents in water by adding alkalinity to solutions.

- Emulsifiers: These liquids can carry oils into water solutions, creating a liquid-in-liquid solution.

- Saponifiers: These are materials that will react with fatty acids and other carboxyl groups to form water-soluble soaps that can dissolve into the water solution.

- Sequestering agents: These are materials that bind with calcium, magnesium and other metals in hard water that detract from the cleaner's overall cleaning ability. Sequestering agents can bind with more than one metal ion at a time.

- Chelating agents: These similar to sequestering agents but bind to one metal ion only.

The combination of water, solvents, surfactants, and saponifiers can be as effective as solvent cleaning but often requires a change in the cleaning process. In a high precision application where residues cannot be tolerated, a rinsing process is often required with water-based chemistries. Batch or in-line cleaning systems generally have a rinse and dry cycles to overcome these issues.

Characteristics of water-based cleaners

Aqueous cleaners can achieve very similar cleaning levels as solvent-based cleaning chemistries, but there are specific differences:

- Evaporation Rate: Water-based cleaners function in a much narrow range of evaporation range when compared to solvent cleaners. While solvent cleaners' evaporation range can be instantaneously taking months, water-based degreasers are typically in a much narrower range. They usually are not left to evaporate independently and can commonly be used in a cold or hot soak application.

- Temperature Characteristics: Cleaning temperatures for water-based chemistries can range from room temperature up to about 80C, depending on the cleaner and formulation. Although this provides a great deal of process variability, this is much more limited than solvent cleaners. Solvent temperature cleaning range can be much more comprehensive based on the variety of solvents available, from below 0C to above 200C.

- Higher surface tension: In general, water-based cleaners have higher surface tensions when compared to solvents. Raising the temperature, using different surfactants and emulsifiers, and incorporating spray and drying systems can overcome much of this disadvantage. Still, solvents with low surface tension have a superior ability to wet into and evaporate out of tight spaces for the most closed clearance areas.

- Reactive additives: Some of the reactive additives incorporated into aqueous cleaners can be very aggressive to different metals, plastics, or inks. Once there is a plan to clean anything, we must check the validation of material compatibility with it; this includes ensuring no reactive material is left behind from the rinse process and verifying the product will function expectedly in all expected environments. Trace quantities of some of these materials may contribute to electrical leakage, coating dewetting, and various other defects.

- Rinse and Drying: As noted above, rinsing and drying removes any cleaner components and solubilized contaminants. While some solvent cleaning systems also require a rinse and dry process, water-based systems are usually more involved than vapor degreasing applications.

- Environmental Impact: Ecological impact concerns apply to both solvent and aqueous cleaners. Global, national, state, and municipal regulations continue to limit the cleaning choices available to manufacturers:

- Montreal and Kyoto protocols limit categories of substances like CFC's (chlorofluorocarbons), HCFCs (hydrochlorofluorocarbons), and HFC's (hydrofluorocarbons) due to ozone depletion, global warming, and other environmental concerns.

- EPA (Environmental Protection Agency) and state agencies like Cal-OSHA (California OSHA) limit personnel exposure to toxic chemicals.

- CARB (California Air Review Board) restricts smog-producing VOC's (volatile organic compounds) in cleaners based on specific cleaning categories.

- Hazardous Air Pollutants (HAP's). Hazardous air pollutants (HAPs) are known or suspected to cause cancer or other serious health effects, such as reproductive effects or congenital disabilities, or adverse environmental effects. Some solvents are considered HAP, and in general water-based chemistries do not contain HAPs.

- Priority Pollutant List. These are a set of chemicals that the EPA regulates and has analytical test methods for detecting under the Clean Water Act. Here again, several solvents are on this list, while aqueous cleaning chemistries are not.

These regulatory pressures force manufacturers to evaluate new cleaners and cleaning processes to overcome these hurdles. In response, water-based cleaners are becoming more common in the industry.

WHICH CLEANING CHEMISTRY IS BEST FOR YOU?

Both cleaning technologies can be beneficial in terms of performance. The cleaning ability depends on what is being cleaned off the surface, the substrate being cleaned, and the process constraints and requirements. All three parameters must work in together for the best cleaning results.

To choose between an aqueous cleaner vs. a solvent, one must evaluate your unique application, requirements, and goals. Then, you must consider the safety, performance, and cost of the solution. A good cleaning agent made specifically for removing handling soils may not remove machine greases. A cleaner that works well on stainless steel may not be compatible with glass lenses, and a cleaner that eliminates machining oil may not be clean enough for a liquid oxygen line.

The bottom line is that it's impossible to make an overall credible judgment of the superiority of solvent or water-based cleaners without evaluating the user's unique situation. Luckily, even with the ever-mounting regulations, there's still an array of choices that include both solvents and water-based cleaners.

Epochem brand of cleaning chemicals are currently the dominant brand in cleaning chemicals in Nigeria.

If you are interested in buying quickly, buy from the most popular online shop for industrial chemicals.

For your unique requirements, you may talk to our experts on industrial and general-purpose cleaning.

Recent Posts

-

How to Choose the Right Industrial Cleaning Service Provider

Key takeawayThoroughly Assess Your Needs and Providers: Understand your specific industrial cle …Jul 26, 2024 -

Floor Paint Maintenance: How to Keep Your Floors Looking Their Best

Maintaining your painted floors is essential for preserving their beauty and extending their lifespa …Jul 25, 2024 -

The Best Floor Paint for Different Types of Flooring

When it comes to revitalizing your home's flooring, choosing the right paint can make all the d …Jul 19, 2024